EPDM Self-adhesive Waterproof Membrane for Rooftop Rubber Foam CMAX

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

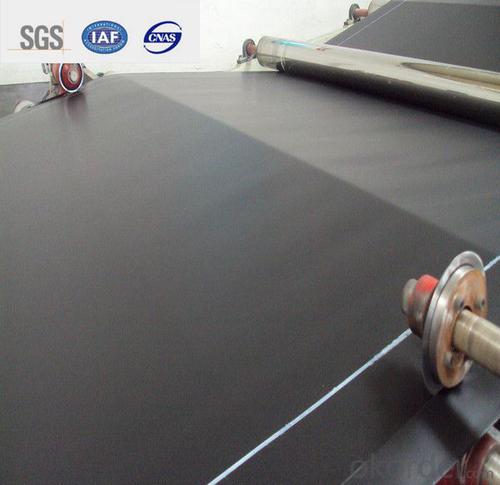

Description Of EPDM Self-adhesive Waterproof Membrane for Rooftop Rubber Foam :

Self adhesive waterproof rolling material:

thickness:1.2/1.5/2.0mm

length/roll:10/20m

width/roll:1.02m

Low temperature:-15 -20,-30

Main Features of EPDM Self-adhesive Waterproof Membrane for Rooftop Rubber Foam :

1) High tear

2) High puncturing strength

3) Great temperature resistance.

4) High dimensional stability

Specifications of EPDM Self-adhesive Waterproof Membrane for Rooftop Rubber Foam :

Material | EPDM Self-adhesive Waterproof Membrane |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

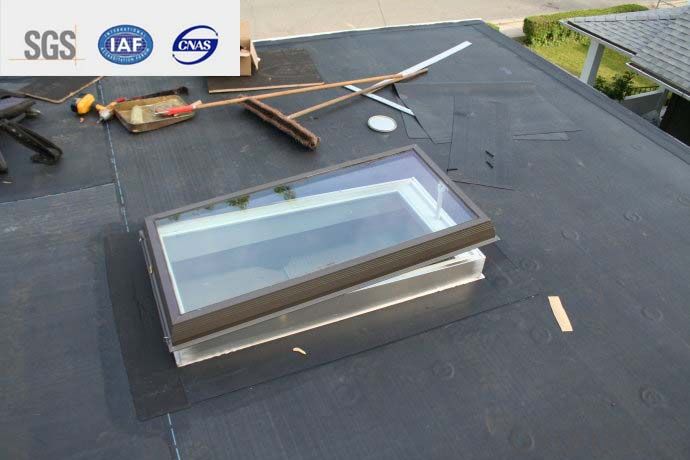

Applications of EPDM Rubber Waterproof Membrane:

1.It is widely used in civil and industry construction.

2.The waterproof,dampproof of the roofs,basements,toilets etc;

3.And the waterproofing of subway,underground,bridges,car parking,tunnels,reserviors,pool etc.

4.SBS modified bitumen waterproof membrane is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions

5.APP specially suitable to areas of high temperature and of strong sunshine.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Are waterproofing membranes resistant to fire?

- No, waterproofing membranes are not inherently resistant to fire.

- Q: Can a waterproofing membrane be used for a commercial building roof?

- A commercial building roof can indeed utilize a waterproofing membrane. In commercial buildings, it is quite common to employ waterproofing membranes to safeguard the roof against water damage and leaks. These membranes typically consist of synthetic materials like PVC or EPDM, which possess exceptional durability and resistance to water penetration. They are applied to the roof surface as a protective layer, effectively preventing water from infiltrating and causing harm to the structure. Moreover, waterproofing membranes are specifically designed to endure various weather conditions, including intense rain, snow, and UV exposure. This makes them suitable for commercial buildings that are exposed to harsh environmental elements. By utilizing a waterproofing membrane, one can ensure the integrity and longevity of a commercial building roof in an effective and long-lasting manner.

- Q: Can a waterproofing membrane be used for wastewater treatment plants or sewage facilities?

- Yes, a waterproofing membrane can be used for wastewater treatment plants or sewage facilities. These facilities often require protection against water infiltration and leakage due to the presence of large amounts of water and potentially corrosive substances. A waterproofing membrane is a versatile solution that can provide a barrier against water penetration, helping to prevent damage to the structure and ensure the proper functioning of the facility. It can be applied to various areas such as walls, floors, roofs, and tanks, helping to maintain a watertight environment and prolong the lifespan of the facility. Additionally, some waterproofing membranes are specifically designed to withstand harsh chemicals, making them suitable for wastewater treatment plants and sewage facilities where corrosive substances may be present.

- Q: Can a waterproofing membrane be used in cold climates?

- Indeed, a waterproofing membrane is suitable for use in cold climates. It is highly advisable to utilize a waterproofing membrane in cold climates to safeguard structures from moisture damage caused by snow, ice, and freezing temperatures. These membranes are engineered to possess flexibility and durability, enabling them to endure extreme temperature fluctuations without experiencing cracks or deterioration. They establish a barrier that thwarts water from permeating the structure, a critical factor in cold climates where water can freeze and expand, resulting in substantial harm to buildings and infrastructure. Additionally, certain waterproofing membranes are specifically formulated to excel in cold weather conditions, offering heightened resistance to freeze-thaw cycles and ensuring long-term protection against water infiltration. Therefore, it is imperative to employ a high-quality waterproofing membrane in cold climates to uphold the integrity and longevity of structures.

- Q: Are waterproofing membranes resistant to chlorine exposure?

- Yes, waterproofing membranes are typically resistant to chlorine exposure.

- Q: What are the potential drawbacks or limitations of using a waterproofing membrane?

- Some potential drawbacks or limitations of using a waterproofing membrane include the potential for installation errors, which can lead to leaks and water infiltration. The membranes can also be prone to damage from sharp objects or heavy foot traffic, requiring regular maintenance and inspections. Additionally, waterproofing membranes may not be suitable for certain applications or environments, such as areas with extreme temperatures or chemical exposure.

- Q: Can waterproofing membranes be applied on roofs?

- Yes, waterproofing membranes can be applied on roofs. In fact, they are commonly used in the construction industry to provide an extra layer of protection against water infiltration. These membranes are typically made of synthetic materials such as PVC, TPO, or EPDM, which are highly resistant to water and can effectively prevent leaks and water damage on roofs. The application of waterproofing membranes on roofs is a proven method to enhance the longevity and durability of the roofing system, especially in areas prone to heavy rainfall or extreme weather conditions. Additionally, waterproofing membranes are flexible and can be easily installed on various types of roofing materials, including concrete, metal, or asphalt shingles. Therefore, if you want to ensure a watertight roof and protect your property from water-related issues, using waterproofing membranes is a reliable and effective solution.

- Q: Can a waterproofing membrane be used for a stadium roof?

- Indeed, a waterproofing membrane proves to be a valuable asset when it comes to shielding a stadium roof. It is a widely adopted solution in the realm of construction, particularly for rooftops, as it effectively wards off water infiltration and safeguards the underlying structure against potential water-related harm. This membrane serves as a protective barrier against moisture and is specifically engineered to endure harsh external elements such as rain, snow, and UV radiation. By employing a waterproofing membrane on a stadium roof, it significantly bolsters its resistance to water, thereby averting leaks. This aspect is of utmost importance as it ensures the stadium's integrity remains intact, while also safeguarding spectators, equipment, and facilities within. Moreover, the versatility of waterproofing membranes is noteworthy, as they are available in various types and materials, allowing for customization to meet the specific requirements and design of the stadium roof.

- Q: Are waterproofing membranes suitable for stadium structures?

- Yes, waterproofing membranes are suitable for stadium structures. Stadiums are exposed to various weather conditions such as rain, snow, and humidity, which can potentially damage the structure if proper waterproofing measures are not taken. Waterproofing membranes provide a protective layer that prevents water infiltration, thus safeguarding the stadium from moisture-related issues like leaks, mold, and corrosion. Stadium structures often have large roof areas and expansive seating areas where water can accumulate, making waterproofing crucial. Membranes can be applied on various surfaces, including concrete, metal, and wood, ensuring a versatile and effective waterproofing solution for stadiums. Moreover, waterproofing membranes offer durability and longevity, which is essential for stadiums that are subjected to heavy usage and constant exposure to the elements. They are designed to withstand thermal expansion and contraction, as well as UV radiation, ensuring long-term protection for the structure. Additionally, waterproofing membranes can be customized to meet specific design requirements, allowing architects and engineers to integrate them seamlessly into the stadium's overall aesthetic. These membranes come in various colors, textures, and finishes, enabling them to blend with the surrounding materials and enhance the visual appeal of the stadium. Overall, waterproofing membranes provide a reliable and effective solution for protecting stadium structures from water damage. They offer durability, versatility, and customization options, making them suitable for any stadium construction or renovation project.

- Q: Can a waterproofing membrane be used for water tanks?

- Yes, a waterproofing membrane can be used for water tanks. Waterproofing membranes are specifically designed to prevent the passage of water and can effectively seal water tanks, ensuring that they remain watertight. These membranes are commonly made from materials such as bitumen, PVC, or EPDM, which provide excellent resistance to water and are capable of withstanding the harsh conditions often found in water tanks. Additionally, waterproofing membranes can be applied to various surfaces, including concrete, metal, and masonry, making them versatile and suitable for different types of water tanks. Overall, using a waterproofing membrane is a reliable solution for ensuring the integrity and longevity of water tanks by preventing water leakage and protecting the surrounding environment from potential water damage.

Send your message to us

EPDM Self-adhesive Waterproof Membrane for Rooftop Rubber Foam CMAX

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords