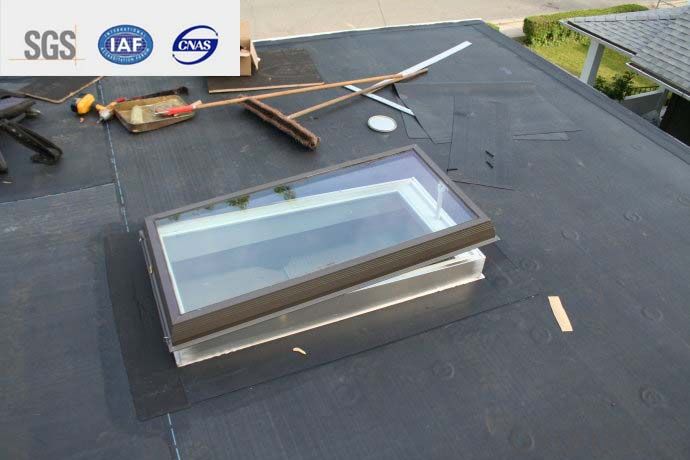

EPDM Self-adhesive Waterproof Membrane for Green Rooftop

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

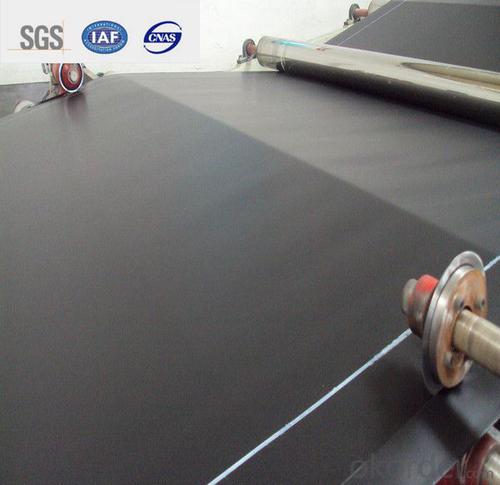

Description Of EPDM Rubber Waterproof Membrane:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Rubber Waterproof Membrane:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Rubber Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be installed in wet conditions?

- No, a waterproofing membrane should not be installed in wet conditions as it requires a dry surface to properly adhere and create an effective barrier against water penetration.

- Q: Can a waterproofing membrane be used on planter boxes?

- Yes, a waterproofing membrane can be used on planter boxes. A waterproofing membrane is typically used to prevent water from seeping through surfaces, and this can be beneficial for planter boxes as it helps to protect the wood or other materials from moisture damage. By applying a waterproofing membrane to the interior of the planter box, it creates a barrier that prevents water from penetrating the material and potentially causing rot or decay. This can extend the lifespan of the planter box and ensure that it remains in good condition for a longer period of time. Additionally, a waterproofing membrane can also help to retain moisture within the planter box, which can be beneficial for the plants or flowers that are being grown. Overall, using a waterproofing membrane on planter boxes can provide added protection and durability.

- Q: Can a waterproofing membrane be used for storage tanks or containment areas?

- Yes, a waterproofing membrane can be used for storage tanks or containment areas. Waterproofing membranes are designed to provide a barrier against water or other liquid penetration, making them suitable for applications where containment is required. These membranes are typically made from materials such as rubber, PVC, or bitumen, which are known for their water-resistant properties. They can be applied to the interior or exterior surfaces of storage tanks or containment areas to prevent leaks and protect the structures from moisture damage. Additionally, waterproofing membranes can also help to prevent the growth of mold or mildew, ensuring a safe and hygienic environment for stored materials or liquids.

- Q: Can a waterproofing membrane be used for an industrial facility?

- Yes, a waterproofing membrane can be used for an industrial facility. It provides a protective barrier against water intrusion, preventing potential damage and ensuring the integrity of the facility's structure.

- Q: How does a waterproofing membrane handle water pressure from adjacent structures?

- A waterproofing membrane is designed to handle water pressure from adjacent structures by creating a barrier that prevents water from penetrating through it. The membrane is typically installed on the exterior side of the structure, such as the foundation walls, and acts as a protective layer against water infiltration. The membrane itself is usually made of a durable and flexible material, such as rubber, PVC, or bitumen, that is resistant to water and can withstand the pressure exerted by water. It is installed in such a way that it forms a continuous and seamless barrier that covers the entire surface of the structure. When water pressure from adjacent structures, such as soil or groundwater, is exerted on the membrane, it resists the pressure and prevents water from seeping through. This is achieved through the combination of the membrane's material properties and the way it is installed. The waterproofing membrane is typically installed with proper surface preparation, ensuring that the surface is clean, smooth, and free from any debris or sharp objects that could potentially damage the membrane. It is then applied using adhesives, heat fusion, or mechanical fastening techniques to create a secure and watertight seal. In addition to the membrane itself, other components, such as drainage systems and protection boards, may be incorporated into the waterproofing system to further enhance its performance and manage water pressure effectively. These additional components help to divert water away from the structure and relieve any excess water pressure that may build up. Overall, a properly installed and maintained waterproofing membrane is designed to handle water pressure from adjacent structures by creating a reliable and durable barrier that prevents water infiltration and protects the structure from potential water damage.

- Q: Can a waterproofing membrane be used for bridge decks and roadways?

- Yes, a waterproofing membrane can be used for bridge decks and roadways. Waterproofing membranes are designed to provide a protective layer that prevents water infiltration, which is essential for the long-term durability and performance of bridge decks and roadways. These membranes help to prevent water damage, such as corrosion and cracking, and also protect the underlying structure from moisture-related issues.

- Q: Is a waterproofing membrane resistant to saltwater or salt damage?

- Yes, a waterproofing membrane is resistant to saltwater or salt damage. Its composition and design make it highly durable and capable of withstanding the corrosive effects of saltwater, ensuring long-term protection against leaks and seepage.

- Q: Can a waterproofing membrane be used in crawl spaces?

- Yes, a waterproofing membrane can be used in crawl spaces. Crawl spaces are vulnerable to moisture and water intrusion, which can lead to issues such as mold, mildew, and structural damage. Using a waterproofing membrane can help protect the crawl space from water damage by creating a barrier against moisture. The membrane is typically installed on the walls and floor of the crawl space, effectively sealing it off from water and preventing water from seeping in. This can be especially beneficial in areas with high water table levels or frequent flooding. Additionally, the waterproofing membrane can also help to improve indoor air quality by preventing the growth of mold and reducing the presence of allergens. It is important to consult with a professional to determine the most suitable waterproofing membrane and installation method for a specific crawl space, as different crawl spaces may have varying requirements.

- Q: Are there any specific considerations for installing a waterproofing membrane on concrete surfaces?

- Yes, there are several specific considerations for installing a waterproofing membrane on concrete surfaces. Firstly, it is important to ensure that the concrete surface is clean, dry, and free from any loose materials, oil, grease, or other contaminants. Any dirt or debris on the surface can prevent proper adhesion of the waterproofing membrane, compromising its effectiveness. Secondly, it is crucial to inspect the concrete surface for any cracks, spalling, or other damage. These defects should be repaired prior to installing the waterproofing membrane, as they can allow water to penetrate through the membrane and compromise its ability to protect the concrete. Additionally, the type of waterproofing membrane chosen should be suitable for the specific conditions and requirements of the project. There are various types of membranes available, such as sheet membranes, liquid-applied membranes, or cementitious coatings. Each type has different application methods, durability, flexibility, and resistance to various substances, so it is important to select the appropriate membrane for the specific concrete surface and its intended use. Furthermore, the installation of the waterproofing membrane should be carried out in accordance with the manufacturer's instructions. This includes applying the membrane at the recommended thickness, ensuring proper overlap and adhesion of the membrane seams, and using any recommended primers or adhesives. Lastly, it is important to consider the long-term maintenance and durability of the waterproofing membrane. Regular inspections, maintenance, and repairs should be conducted to ensure the membrane remains intact and effective in preventing water penetration.

- Q: Can a waterproofing membrane be used in agricultural structures?

- Yes, a waterproofing membrane can be used in agricultural structures. Agricultural structures such as barns, greenhouses, and storage facilities often require protection from moisture and water damage. A waterproofing membrane is a durable and flexible material that can be applied to different surfaces such as roofs, walls, and floors to prevent water infiltration. It acts as a barrier, preventing water from seeping into the structure and causing damage to the building materials, equipment, and stored crops. Additionally, a waterproofing membrane can also help regulate the temperature and humidity levels within the agricultural structure, creating a more controlled and optimal environment for crops, livestock, and equipment. Overall, using a waterproofing membrane in agricultural structures can help ensure the longevity and functionality of the building while protecting the valuable assets inside.

Send your message to us

EPDM Self-adhesive Waterproof Membrane for Green Rooftop

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords