EPDM Self-adhesive Waterproof Membrane for Green Roofing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

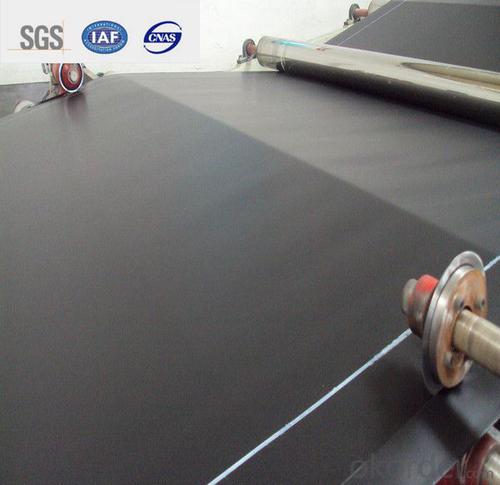

Description Of EPDM Rubber Waterproof Membrane:

1. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

2. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Rubber Waterproof Membrane:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

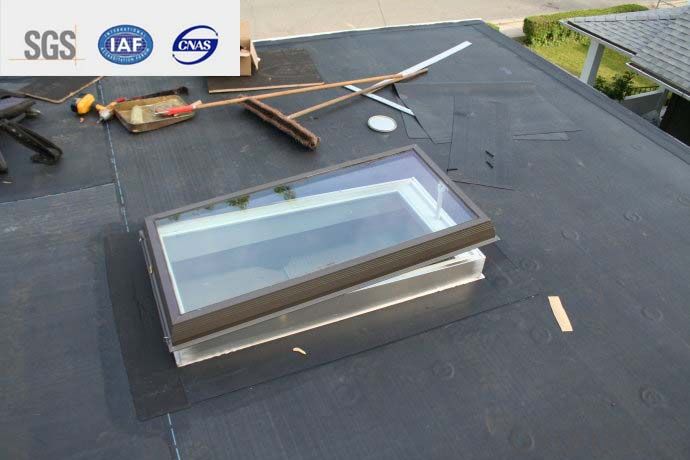

Applications of EPDM Rubber Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used in conjunction with soundproofing materials?

- Yes, a waterproofing membrane can be used in conjunction with soundproofing materials. While the primary function of a waterproofing membrane is to prevent water infiltration, it can also contribute to sound insulation to some extent. However, for optimal soundproofing, it is recommended to use dedicated soundproofing materials such as acoustic insulation or soundproof panels in addition to the waterproofing membrane.

- Q: Can a waterproofing membrane be applied on both horizontal and vertical surfaces?

- Yes, a waterproofing membrane can be applied on both horizontal and vertical surfaces. Waterproofing membranes are designed to create a protective barrier against water penetration and can be effectively used on various surfaces, including both horizontal surfaces like roofs and decks, as well as vertical surfaces such as walls and foundations.

- Q: Can a waterproofing membrane be used for a bathroom?

- Yes, a waterproofing membrane can be used for a bathroom.

- Q: Can a waterproofing membrane be customized or tailored to specific project requirements?

- Indeed, specific project requirements can be met through the customization or tailoring of a waterproofing membrane. There are various types and materials available, including bituminous, synthetic, and liquid-applied membranes. These membranes can be adjusted or modified to suit the particular needs of a project. Customization involves factors such as the thickness or weight of the membrane, the type of reinforcement utilized, the application method, and the project's specific performance requirements. For instance, heavy traffic areas may require a thicker or more durable membrane to withstand substantial loads, while projects in harsh climates may necessitate a membrane with enhanced resistance to UV radiation or extreme temperatures. Moreover, the membrane can be tailored to different substrates or surfaces, such as concrete, metal, or wood, by utilizing compatible adhesives or primers. This ensures proper bonding and extends the lifespan of the waterproofing system. Furthermore, certain waterproofing membranes offer customizable options for color or appearance, enabling them to seamlessly blend with the overall aesthetic of the project. In conclusion, the customization of a waterproofing membrane allows for its specific design and engineering to cater to the unique requirements of each project. This ensures optimal performance and long-lasting protection against water damage.

- Q: Can a waterproofing membrane be used for plant rooms?

- Yes, a waterproofing membrane can be used for plant rooms. Waterproofing membranes are commonly used in various applications, including plant rooms, to prevent water penetration and protect the structure from moisture damage. These membranes help maintain a dry and controlled environment, which is essential for the proper functioning and longevity of equipment in plant rooms.

- Q: Can a waterproofing membrane be used in shower pans?

- Yes, a waterproofing membrane can be used in shower pans. In fact, it is highly recommended to use a waterproofing membrane in shower pans to prevent any water leakage or damage to the underlying structure. A waterproofing membrane acts as a barrier, preventing water from seeping through the shower pan and into the subfloor or surrounding walls. This helps to maintain the integrity and longevity of the shower pan and the overall shower system. Additionally, a waterproofing membrane can also protect against mold and mildew growth, ensuring a safe and hygienic environment. Therefore, using a waterproofing membrane in shower pans is an essential step in ensuring a durable and water-resistant shower installation.

- Q: Can a waterproofing membrane be used for schools or universities?

- Yes, a waterproofing membrane can definitely be used for schools or universities. Waterproofing membranes are commonly used in various construction projects, including educational institutions, to protect the building from water damage. These membranes are applied to the exterior surfaces of the structure, such as roofs, walls, or foundations, to create a barrier that prevents water infiltration. By implementing a waterproofing membrane, schools and universities can ensure that their buildings remain dry and free from water-related issues such as leaks, mold growth, or structural damage. This not only helps to maintain the integrity and longevity of the building but also provides a safe and comfortable environment for students, staff, and visitors. Additionally, waterproofing membranes can also be used in areas such as bathrooms or wet laboratories to prevent water seepage, which is especially important in educational settings where high traffic and frequent use of water are common. Overall, using a waterproofing membrane in schools or universities is a proactive measure to protect the infrastructure, enhance durability, and promote a conducive learning environment.

- Q: Can a waterproofing membrane be used on tile surfaces?

- Yes, a waterproofing membrane can be used on tile surfaces. A waterproofing membrane is a thin layer of material that is designed to prevent water or moisture from penetrating through to the underlying surface. It is commonly used in areas where water exposure is high, such as bathrooms, showers, or outdoor areas. When applied properly, a waterproofing membrane can create a barrier that protects the tile surface from water damage, preventing issues such as mold, mildew, or tile deterioration. It is important to ensure that the waterproofing membrane is compatible with the type of tile being used and that it is installed correctly to ensure maximum effectiveness.

- Q: Can a waterproofing membrane be used on nickel surfaces?

- Yes, a waterproofing membrane can be used on nickel surfaces. Waterproofing membranes are commonly used in construction and building projects to protect surfaces from water damage and moisture intrusion. They create a barrier that prevents water from penetrating through the surface and causing damage. Nickel surfaces, like any other metal surfaces, can be susceptible to corrosion and damage from water exposure. By applying a waterproofing membrane, the nickel surface can be effectively protected from water and moisture, extending its lifespan and maintaining its integrity. However, it is important to ensure that the specific waterproofing membrane being used is suitable for application on nickel surfaces. Different membranes may have different compatibility requirements, so it is recommended to consult with the manufacturer or a professional to ensure proper application and compatibility.

- Q: Does a waterproofing membrane require any specific curing time before it can be exposed to water?

- Yes, a waterproofing membrane generally requires a specific curing time before it can be exposed to water. The curing time allows the membrane to fully dry, set, and create a strong bond with the substrate it is applied to. This ensures its effectiveness in preventing water penetration. The specific curing time can vary depending on the type of membrane and manufacturer's instructions, so it is crucial to follow the recommended curing period before subjecting it to water exposure.

Send your message to us

EPDM Self-adhesive Waterproof Membrane for Green Roofing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords