EPDM Pond Liner/Roofing Membrane Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

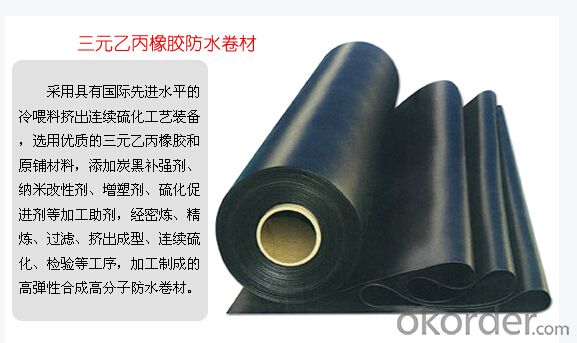

1. Product Specification for EPDM Waterproof Membrane:

There are two installation ways.one is full sticking,the other is hot welding.

Item | Thick(mm) | Width | Length(m) | Color |

Spe | 1.0—2.0 | 1.2m/2m/3m/4m | 20 | Black |

Deviation | -1 +15 | --1 | Multicolor |

2.Product Technicial Data for EPDM Waterproof Membrane:

No. | Item | Technical index | ||

JL1 | JF1 | |||

1 | Tensile strength at break Mpa | Normal temperature≥ | 7.5 | 4.0 |

60°C≥ | 2.3 | 0.8 | ||

2 | Elogation at break | Normal temperature≥ | 450 | 400 |

-20°C≥ | 200 | 200 | ||

3 | Tearing strength KN/m≥ | 25 | 18 | |

4 | Impermeability 30minutes No leak | 0.3Mpa | 0.3Mpa | |

5 | Low temperature flexibility °C≤ | -40 | -30 | |

6 | Heat air ageing 80°C x 168h | Tensile strength retention rate % ≥ | 80 | 90 |

Elogation retention rate % ≥ | 70 | 70 | ||

Apperance of 100% elogation | no crack | no crack | ||

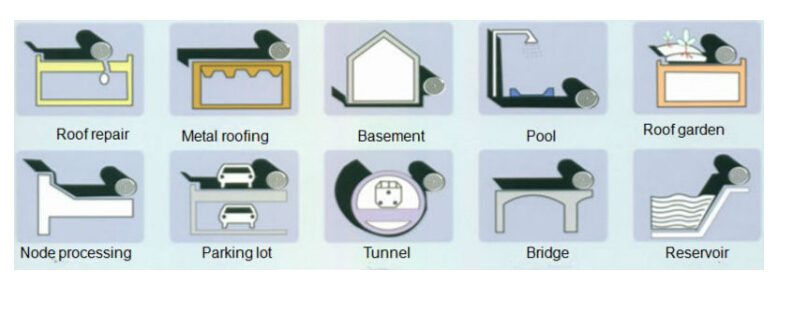

3. Product Application:

Widely used in roofs, basement, toilet ,swimming pool, and all kinds of industry and civil building waterproofing, reservoir, vivicism, bridge, underground, tunnel and dam waterproofing ,especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation

4. Some photos:

- Q: Can waterproofing membranes be used on expansion joints?

- Yes, waterproofing membranes can be used on expansion joints. These membranes are designed to create a barrier against water penetration and can effectively seal and protect expansion joints from moisture damage.

- Q: Are waterproofing membranes resistant to saltwater?

- Yes, waterproofing membranes are generally resistant to saltwater. These membranes are designed to create a barrier that prevents water from penetrating through surfaces such as roofs, walls, or foundations. They are made from materials like rubber, polyethylene, or PVC, which are inherently resistant to the corrosive effects of saltwater. This resistance allows waterproofing membranes to effectively protect structures and surfaces from water damage, even in saltwater environments. However, it is essential to choose a waterproofing membrane specifically designed for saltwater applications to ensure optimal performance and longevity.

- Q: Can a waterproofing membrane be used in earthquake-prone areas?

- Yes, a waterproofing membrane can be used in earthquake-prone areas. Waterproofing membranes are designed to provide a barrier against moisture penetration, and they can also offer some degree of flexibility and elasticity. This allows them to withstand the movement and vibrations caused by earthquakes, helping to protect the structure from water damage and potential leaks. However, it is important to ensure that the chosen membrane meets the specific requirements and standards for earthquake-prone areas to ensure its effectiveness and durability.

- Q: Can a waterproofing membrane be used for underground bunkers?

- Yes, a waterproofing membrane can be used for underground bunkers. Waterproofing membranes are designed to provide a barrier against water infiltration, which makes them suitable for protecting underground structures such as bunkers from moisture and water damage.

- Q: Is a waterproofing membrane resistant to hydrochloric acid or other corrosive substances?

- Waterproofing membranes are designed to resist water penetration and are commonly used as a barrier against moisture. However, it is important to understand that the resistance of a waterproofing membrane to hydrochloric acid or other corrosive substances may vary depending on the specific material used. Some waterproofing membranes, like those made from bituminous or rubberized asphalt materials, have a higher resistance to chemicals such as hydrochloric acid. These membranes are often utilized in industrial settings where exposure to corrosive substances is frequent. They are specifically engineered to endure the effects of these substances and offer long-lasting protection. On the contrary, other types of waterproofing membranes, such as those composed of polyvinyl chloride (PVC) or high-density polyethylene (HDPE), may have a lower resistance to corrosive substances like hydrochloric acid. These membranes are typically employed in less demanding applications where chemical exposure is not a significant concern. Regardless, it is essential to refer to the manufacturer's specifications and guidelines when assessing the resistance of a particular waterproofing membrane to hydrochloric acid or other corrosive substances. The manufacturer can provide detailed information on the membrane's chemical resistance properties and offer guidance on its suitability for specific applications involving corrosive substances.

- Q: Can a waterproofing membrane be used for balconies and terraces?

- Yes, a waterproofing membrane can be used for balconies and terraces. Waterproofing membranes are often used in construction to protect these outdoor spaces from water damage and leakage. They provide an effective barrier against moisture and ensure the durability and longevity of balconies and terraces.

- Q: Can a waterproofing membrane be used on below-grade walls?

- Yes, a waterproofing membrane can be used on below-grade walls to prevent water infiltration and moisture damage.

- Q: Can waterproofing membranes be used in cold climates?

- Yes, waterproofing membranes can be used in cold climates. They are designed to withstand extreme temperatures, including freezing conditions, and provide effective protection against water penetration.

- Q: Can waterproofing membranes be used on elevator pits?

- Indeed, elevator pits can benefit from the utilization of waterproofing membranes. Given their underground location, elevator pits are susceptible to water infiltration, which can lead to detrimental water damage and leaks. To combat these moisture-related issues, waterproofing membranes offer a highly effective solution by preventing water penetration and safeguarding elevator pits. Typically composed of rubber, polyurethane, or bitumen, these membranes are specifically designed to create a watertight barrier. Through their application on the walls and floor of the elevator pit, they form a seamless and durable protective layer. As a result, this membrane system ensures the maintenance of a dry pit, consequently preventing water damage to the elevator components and ensuring the safe and reliable operation of the elevator.

- Q: Can waterproofing membranes be used on concrete reservoirs?

- Yes, waterproofing membranes can be used on concrete reservoirs. Waterproofing membranes are designed to provide a protective barrier against moisture and water penetration, making them an ideal choice for concrete reservoirs that need to be watertight. These membranes are typically applied to the concrete surface, creating a seamless and durable waterproof layer. They can effectively prevent water leakage, seepage, and dampness, ensuring the integrity and longevity of the concrete reservoir. Additionally, waterproofing membranes can also provide resistance against chemicals, UV rays, and other environmental factors, further enhancing the durability and performance of the concrete reservoir. It is important to choose a high-quality waterproofing membrane that is specifically designed for use on concrete structures and to follow the manufacturer's instructions for proper application and maintenance.

Send your message to us

EPDM Pond Liner/Roofing Membrane Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords