EPDM Coiled Waterproof Membrane with 1.5mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Coiled Waterproof Membrane with 1.5mm Thickness

Description Of EPDM Coiled Waterproof Membrane with 1.5mm Thickness:

1. Excellent physical and mechanical performance, high tearing resistance;good deformation adaptability, high puncture resistance;

2. High aging resistance, high UV resistance, anti-acid & alkali;

3. Excellent low & high temperature resistance, innocuous, long life span;

4. Perfect water proof performance, seepage and humidity resistance.

Main Features of EPDM Coiled Waterproof Membrane with 1.5mm Thickness:

A.Polyester based SBS Modified Bitumen Waterproofing Membrane

a. Strong impermeability

b. High tensile strength, elongation, ability to adapt the grassroots shrinkage deformation and cracking

c. Puncture-resistant, broken resistant, tear-resistant

d. The corrosion resistance, resistance to mildew, weathering good

e. Construction convenient, hot-melt can be operated Four Seasons Construction, reliable joints

B. Fiberglass based SBS Modified Bitumen Waterproofing Membrane

a. High tensile strength, stability of a good size

b. High Temperature good performance

c. Damage resistance, corrosion resistance, resistance to mildew, weathering good performance

d. Good construction performance, reliable joints.

Specifications of EPDM Coiled Waterproof Membrane with 1.5mm Thickness:

| Material | EPDM Rubber |

| Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

| Thick | 1.2mm, 1.5mm, 2.0mm |

| Type | Vulcanized & Weldable |

| Pattern | Non-reinforced (homogeneous) |

| Certificate | ISO9001/14001 |

Applications of EPDM Coiled Waterproof Membrane with 1.5mm Thickness:

geomembrane used in groundsill of road, highway, railway and waterproof layer of swelling clay and wet collapsed loess.Geomembrane can be widely used in areas of garbage burying, waste disposal and underground construction projects.such as below:

- aquaculture ponds

- Ouchi root barrier membrane

- Floating baffles;

- Process wastewater

- Stormwater impoundments;

- Secondary containment;

- Spill containment

- Manure and biogas tanks and covers

- Potable water tanks and covers;

- Sludge Drying beds;

- Bioremediation covers & liners;

- Leachate ponds

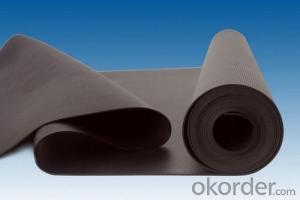

IMages of EPDM Coiled Waterproof Membrane with 1.5mm Thickness:

FAQ of EPDM Coiled Waterproof Membrane with 1.5mm Thickness:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used in renovation projects?

- Indeed, renovation projects can greatly benefit from the utilization of a waterproofing membrane. The incorporation of this crucial component is vital in guaranteeing the durability and long-lasting nature of the structure being renovated. Its primary purpose is to establish a barrier that effectively prevents water infiltration, thereby shielding the building from any potential harm or leaks caused by water. Throughout the course of a renovation project, it is quite common to come across areas where water resistance is of utmost importance. These areas typically include basements, bathrooms, showers, balconies, and roofs. By applying a waterproofing membrane in these specific locations, one can effectively mitigate any moisture-related issues, inhibit the growth of mold, and prevent any structural damage that may arise as a result of water seepage. It is worth noting that waterproofing membranes can be utilized in a wide range of renovation projects, spanning across residential, commercial, and industrial settings. Regardless of whether it is a minor bathroom renovation or a larger-scale refurbishment of a commercial building, the incorporation of a waterproofing membrane will undoubtedly fortify the structure against any water-related complications. Additionally, it is important to mention that there are various options available when it comes to waterproofing membranes. These options encompass liquid-applied membranes, sheet membranes, and cementitious coatings. The availability of these choices ensures that one can select the most suitable membrane for a particular renovation project, taking into consideration factors such as budget, substrate, and the desired level of waterproofing. To summarize, the inclusion of a waterproofing membrane is an indispensable element in renovation projects, as it serves to safeguard against water damage and guarantees the longevity of the renovated structure. By opting for the utilization of a waterproofing membrane, property owners can experience a sense of tranquility, knowing that their renovated space is adequately protected against any potential water-related complications.

- Q: Does a waterproofing membrane provide any insulation against temperature fluctuations?

- Insulation against temperature fluctuations is not provided by a waterproofing membrane. The main purpose of a waterproofing membrane is to hinder the infiltration of water or moisture into the safeguarded region. It functions as a shield to maintain the structure's dryness and safeguard it from potential water harm. Although it might provide a certain level of thermal resistance based on its thickness and material characteristics, it is not crafted or intended to furnish insulation against temperature fluctuations. In construction, materials such as insulation foam or insulation boards are commonly employed to offer insulation.

- Q: Can a waterproofing membrane be used on underground parking structures?

- Yes, a waterproofing membrane can be used on underground parking structures. These membranes are specifically designed to prevent water infiltration and are commonly used in below-grade applications such as underground parking garages to protect the structure from water damage and moisture-related issues.

- Q: Can a waterproofing membrane be applied to tiled surfaces?

- Certainly! A tiled surface can indeed receive the application of a waterproofing membrane. In reality, it is customary to utilize a waterproofing membrane beneath tiled surfaces, particularly in regions susceptible to moisture like bathrooms, showers, and kitchen backsplashes. The waterproofing membrane serves as a shield, thwarting water infiltration into the foundation, thereby safeguarding both the tiles and the underlying structure against water-related harm. Before applying the waterproofing membrane for best outcomes, it is crucial to ensure that the tiled surface is adequately prepared and devoid of any fissures or impairments.

- Q: Can a waterproofing membrane be used for docks or marinas?

- Yes, a waterproofing membrane can be used for docks or marinas. It helps to protect the structure from water damage and prevent leakage.

- Q: Can a waterproofing membrane be used in interior or exterior applications?

- Yes, a waterproofing membrane can be used in both interior and exterior applications. It is commonly used in basements, bathrooms, and other areas prone to moisture and water infiltration. Additionally, it can also be applied to exterior surfaces such as foundations, roofs, and balconies to prevent water damage and maintain the integrity of the structure.

- Q: Can a waterproofing membrane be used on aluminum surfaces?

- Indeed, aluminum surfaces can benefit from the application of a waterproofing membrane. Such membranes possess great versatility, enabling their use on a wide range of surfaces, including aluminum. Their purpose is to create a safeguarding barrier against water and moisture, effectively preventing any potential leaks or water-related harm. By employing a waterproofing membrane on aluminum surfaces, the material's longevity can be significantly extended as it remains protected from the detrimental effects of corrosion and rust, which are often triggered by water exposure. Nevertheless, it is imperative to carefully select a waterproofing membrane that is both compatible with aluminum and suitable for the specific application in order to achieve the most optimal outcomes.

- Q: What is waterproofing membrane?

- Waterproof membrane is mainly used for building walls, roofs, as well as tunnels, highways, landfills, etc., to resist the external rain, groundwater leakage can be curled into a roll of flexible building materials, as the basis for engineering And no leakage between the building connection, the entire project is the first waterproof barrier, the entire project plays a vital role. The main products are asphalt waterproofing membrane and polymer waterproofing membrane.

- Q: Can waterproofing membranes be used on concrete slabs?

- Concrete slabs can indeed utilize waterproofing membranes. In fact, it is a widely adopted technique to shield concrete slabs from water harm. The purpose of waterproofing membranes is to establish a barrier that halts water infiltration into the concrete surface. This becomes particularly crucial for regions susceptible to moisture, like basements, balconies, or swimming pools. Through the application of a waterproofing membrane, the concrete slab effectively safeguards itself against water infiltration, which might otherwise trigger cracks, erosion, or the growth of mold. Moreover, these membranes have the added benefit of bolstering the overall longevity and durability of the concrete slab.

- Q: Can a waterproofing membrane be used for below-grade applications?

- Yes, a waterproofing membrane can be used for below-grade applications. It is commonly used in construction projects to prevent water penetration and protect the foundation of below-ground structures such as basements and underground parking garages.

Send your message to us

EPDM Coiled Waterproof Membrane with 1.5mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords