EPDM Coiled Rubber Waterproof Membrane/waterproofing membrane/lastomeric waterproofing membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

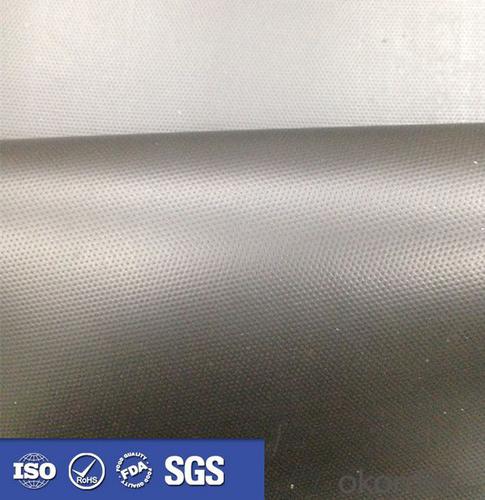

Description Of EPDM Coiled Rubber Waterproof Membrane:

Self adhesive waterproof rolling material:

thickness:1.2/1.5/2.0mm

length/roll:10/20m

width/roll:1.02m

Low temperature:-15 -20,-30

Main Features of EPDM Coiled Rubber Waterproof Membrane:

1) High tear

2) High puncturing strength

3) Great temperature resistance.

4) High dimensional stability

Specifications of EPDM Coiled Rubber Waterproof Membrane:

Material | EPDM Self-adhesive Waterproof Membrane |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of EPDM Coiled Rubber Waterproof Membrane:

1.It is widely used in civil and industry construction.

2.The waterproof,dampproof of the roofs,basements,toilets etc;

3.And the waterproofing of subway,underground,bridges,car parking,tunnels,reserviors,pool etc.

4.SBS modified bitumen waterproof membrane is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions

5.APP specially suitable to areas of high temperature and of strong sunshine.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used on bridges?

- Bridges can indeed benefit from the application of a waterproofing membrane. It is quite common to utilize waterproofing membranes during bridge construction and rehabilitation projects in order to safeguard the bridge deck against water infiltration. These membranes are specifically designed to create a seamless and robust barrier, effectively preventing water from reaching the underlying bridge structure. By implementing a waterproofing membrane on the bridge deck, it significantly prolongs the lifespan of the bridge by minimizing moisture-induced damage and thwarting the corrosion of reinforcement steel. Moreover, these membranes also aid in diminishing the potential for freeze-thaw damage, cracking, and deterioration of the bridge deck. All in all, incorporating a waterproofing membrane on bridges is an efficacious approach to ensure the enduring durability and structural integrity of the bridge.

- Q: Can a waterproofing membrane be used in rooftop gardens or green roofs?

- Yes, a waterproofing membrane can be used in rooftop gardens or green roofs. In fact, it is essential to have a reliable waterproofing system in place to protect the structure beneath the garden or roof from water damage. A waterproofing membrane acts as a barrier, preventing water from seeping into the building or causing structural issues. It is typically installed beneath the soil or growing medium of the rooftop garden or green roof, ensuring that water is properly drained and doesn't compromise the integrity of the building. Additionally, these membranes are designed to withstand the exposure to UV rays, temperature fluctuations, and root penetration, making them suitable for long-term use in rooftop gardens or green roofs.

- Q: Are waterproofing membranes suitable for rooftop gardens?

- Yes, waterproofing membranes are suitable for rooftop gardens. As rooftop gardens are located on top of buildings, it is essential to have proper waterproofing in place to prevent water leakage and damage to the structure. Waterproofing membranes are specially designed to create a barrier that prevents water from seeping into the building. These membranes are typically made of materials such as rubber, PVC, or modified bitumen, which are highly resistant to water penetration. Rooftop gardens involve the use of soil and plants, which require regular watering. Without a reliable waterproofing system, excess water from irrigation or rainfall can seep into the building, leading to issues like water damage, mold growth, and structural deterioration. Waterproofing membranes provide a durable and long-lasting solution to this problem by effectively sealing the rooftop and preventing any water infiltration. Moreover, waterproofing membranes can also offer additional benefits for rooftop gardens. They act as a protective layer against root penetration, preventing plant roots from damaging the roof structure. Additionally, these membranes can help to regulate the temperature of the building by reducing heat absorption from the sun, thereby improving energy efficiency. It is important to note that the selection and installation of waterproofing membranes should be done by professionals with expertise in waterproofing systems. They will ensure that the membranes are correctly installed, free from any defects or punctures, and properly integrated with other roofing components. In conclusion, waterproofing membranes are indeed suitable for rooftop gardens as they provide the necessary protection against water ingress, root penetration, and structural damage. By investing in a reliable waterproofing system, rooftop gardens can thrive while maintaining the integrity and longevity of the building beneath.

- Q: Are waterproofing membranes resistant to chlorine exposure?

- Yes, waterproofing membranes are typically resistant to chlorine exposure.

- Q: Is a waterproofing membrane resistant to impact damage?

- A waterproofing membrane is generally not designed to be resistant to impact damage. Its primary function is to prevent water infiltration and protect the underlying structure from moisture damage. While some membranes may have a certain level of impact resistance, it is not their main characteristic. To protect the membrane from impact damage, additional measures like installing protective layers or using impact-resistant materials may be necessary.

- Q: Can a waterproofing membrane be used for an industrial facility?

- An industrial facility can utilize a waterproofing membrane. Such a membrane is a layer of protection that is applied to surfaces in order to prevent water from penetrating and causing moisture damage. Industrial facilities, including manufacturing plants, warehouses, and processing plants, often require effective waterproofing to safeguard their structures, equipment, and inventory against water damage. Industrial facilities commonly face exposure to various water sources, such as rain, leaks, or spills. Additionally, these facilities may experience high humidity levels or engage in water-intensive processes. By using waterproofing membranes, a reliable barrier against water intrusion can be established, thereby preventing damage and corrosion to the facility's structure, machinery, and products. Waterproofing membranes are designed to be durable and long-lasting, capable of withstanding harsh industrial conditions and heavy traffic or equipment. They come in different materials, such as bitumen, PVC, EPDM, or polyurethane, providing flexibility in selecting the most appropriate membrane for specific industrial applications. Moreover, waterproofing membranes offer additional advantages beyond water resistance. Certain membranes possess insulation properties, aiding in temperature regulation and reducing energy consumption. They can also enhance the overall safety and hygiene of an industrial facility by inhibiting the growth of mold, mildew, or bacteria that thrive in damp environments. To conclude, the utilization of a waterproofing membrane can prove highly effective in safeguarding an industrial facility from water damage. It establishes a dependable barrier against water intrusion, ensuring the facility's longevity and functionality while protecting valuable assets within it.

- Q: Can a waterproofing membrane be applied to existing structures or is it only suitable for new construction?

- A waterproofing membrane has the capability to be applied to both existing structures and new construction. These membranes are specifically designed to create a barrier against water infiltration, making them suitable for preventing water damage in various areas such as roofs, basements, and foundations. Whether it is an aged building or a recently constructed one, the application of a waterproofing membrane can effectively maintain the dryness of the structure and prevent problems associated with moisture, such as leaks, seepage, and mold growth. However, when applying a waterproofing membrane to an existing structure, it may be necessary to undertake additional preparation and surface treatment in order to ensure proper adhesion and efficiency. It is strongly advised to seek the guidance of an experienced waterproofing contractor who can evaluate the specific requirements of the structure and provide suitable solutions.

- Q: How does a waterproofing membrane handle cracks in the substrate?

- The purpose of a waterproofing membrane is to prevent water from entering through cracks in the substrate. This is achieved by creating a barrier that stops water from penetrating through the cracks. Typically, the membrane is made from a flexible material like rubber or synthetic polymers, allowing it to stretch and move with the substrate without tearing or breaking. When cracks appear in the substrate, the membrane can bridge over them, maintaining its integrity and preventing water from seeping through. Some membranes even have the ability to self-heal, sealing minor cracks on their own and ensuring continuous protection against water ingress. To improve its ability to bridge cracks, the waterproofing membrane can be reinforced with fibers or fabric layers. These reinforcements enhance the tensile strength and flexibility of the membrane, enabling it to effectively span larger cracks or accommodate movement in the substrate without compromising its waterproofing performance. It is important to consider that the waterproofing membrane's ability to handle cracks in the substrate depends on various factors. These include the type and size of the cracks, the movement of the substrate, and the quality of the membrane installation. To maximize the membrane's ability to handle cracks and provide long-lasting waterproofing protection, it is crucial to follow the manufacturer's guidelines and ensure proper surface preparation and installation techniques.

- Q: Is a waterproofing membrane resistant to abrasion?

- A waterproofing membrane is generally able to resist abrasion. Its purpose is to create a protective barrier against water and moisture infiltration. These membranes are typically constructed from durable materials like PVC, TPO, or EPDM, which possess a high resistance to abrasion. Consequently, they can endure normal wear and tear that may arise during installation or due to foot traffic or other mechanical activities. Nonetheless, it is crucial to acknowledge that the level of resistance to abrasion can vary based on the specific type and quality of the membrane, as well as the conditions in which it is employed or utilized. Therefore, it is always advisable to refer to the manufacturer's guidelines and specifications to ensure the proper selection and installation of a waterproofing membrane.

- Q: Can a waterproofing membrane be used in crawl spaces?

- Crawl spaces, being susceptible to moisture and water intrusion, can suffer from issues like mold, mildew, and structural damage. For protection against water damage, using a waterproofing membrane is an effective solution. By installing the membrane on the walls and floor of the crawl space, it creates a barrier that keeps moisture out. This is especially useful in areas with high water table levels or frequent flooding. Moreover, the waterproofing membrane not only safeguards the crawl space but also enhances indoor air quality by inhibiting mold growth and reducing allergens. To determine the most suitable waterproofing membrane and installation method for a specific crawl space, it is advisable to seek professional advice as requirements may differ.

Send your message to us

EPDM Coiled Rubber Waterproof Membrane/waterproofing membrane/lastomeric waterproofing membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords