Aluminum Sheets 4x8 Canada - EN AW-5754 Aluminium Treadplate for Making Caravans

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of EN AW-5754 Aluminium Treadplate for Making Caravans Description

EN AW-5754 Aluminium Treadplate for Making Caravans is one semi-finished aluminium material. The alloy AA5754 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW-5754 Aluminium Treadplate for Making Caravans

EN AW-5754 Aluminium Treadplate for Making Caravans | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW-5754 Aluminium Treadplate for Making Caravans

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW-5754 Aluminium Treadplate for Making Caravans

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW-5754 Aluminium Treadplate for Making Caravans

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

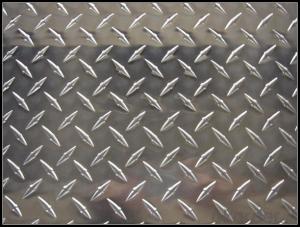

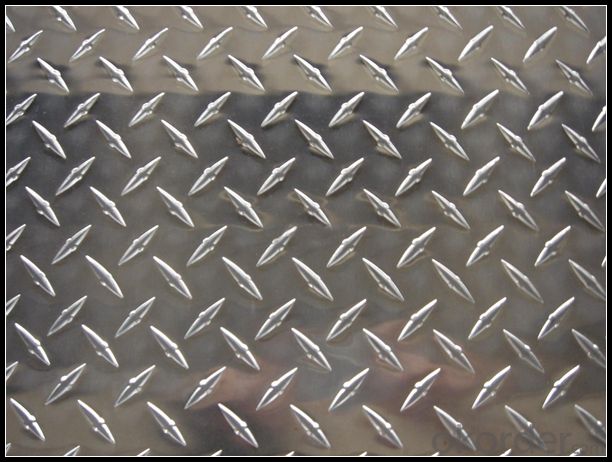

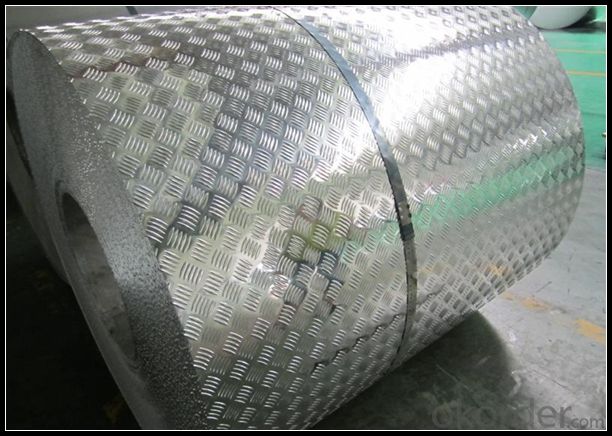

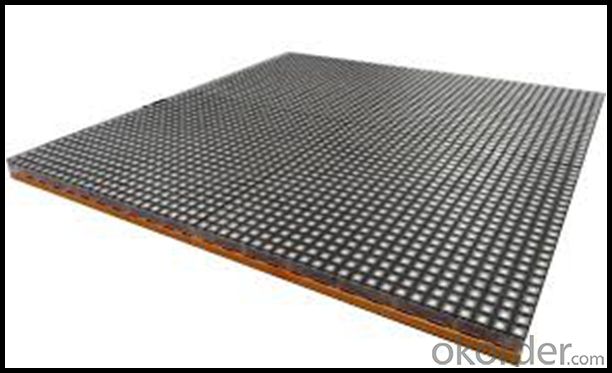

6. Image of EN AW-5754 Aluminium Treadplate for Making Caravans

7. Package and shipping of EN AW-5754 Aluminium Treadplate for Making Caravans

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum sheet be used for soundproofing?

- To a certain degree, aluminum sheet can indeed be utilized for soundproofing. Its dense and rigid composition makes it proficient in obstructing sound transmission. By combining it with other soundproofing materials like foam or mineral wool, its soundproofing capabilities can be further augmented. Nevertheless, it is crucial to acknowledge that aluminum sheet alone may not deliver absolute soundproofing since its thinness can still permit some sound to penetrate. Moreover, ensuring proper installation and sealing of all gaps and openings is imperative to maximize the soundproofing efficacy of aluminum sheet.

- Q: Are the aluminum sheets suitable for manufacturing electronics components?

- Yes, aluminum sheets can be suitable for manufacturing electronics components. Aluminum is preferred for certain applications due to its lightweight, good thermal conductivity, and electrical conductivity properties. However, the suitability of aluminum sheets depends on the specific requirements and design of the electronics components being manufactured.

- Q: Are the aluminum sheets available in different finishes (e.g., brushed, polished)?

- Aluminum sheets can be obtained in various finishes, such as brushed or polished, providing different surface textures and appearances. These finishes are achieved by employing diverse processes that modify the aluminum sheets. Brushed finishes, for instance, create a textured pattern by delicately brushing the surface with fine abrasive materials, resulting in a satin-like look. Conversely, polished finishes involve utilizing abrasive compounds or polishing wheels to buff the surface to a high shine. Consequently, these distinct finishes enable the customization and versatile utilization of aluminum sheets across different industries.

- Q: I would like to use an alloy of copper often called aluminum bronze or aluminum brass for making wire wrapped jewelry but I am unable to find a supplier. An alloy that has no zinc or lead would be best to avoid toxicity problems. This alloy should be principally copper and aluminum but other added materials would be acceptable if not toxic. Nickel, silicon, manganese, and iron are sometimes added to increase performance of the alloy and should be acceptable (no lead or zinc please). The material obviously needs to be bendable enough to work with wire wrapping so if it is brittle it will not work. It should then be at least as usable as aluminum, copper, or stainless steel wire.

- Aluminum okorder which is a site for serious jewelers to share solutions and they might have an answer.

- Q: I have a project on the aluminum element. What are the advantages and disadvantages of this element?...What are the risks/dangers?...Thank you so much ---And please tell me where I could find this information too.

- Advantages Of Aluminium

- Q: Can aluminum sheets be used for architectural sunshades?

- Yes, aluminum sheets can be used for architectural sunshades. Aluminum is a lightweight and durable material that is commonly used in construction and architecture. It can be easily shaped and manipulated to create various designs and configurations for sunshades, providing protection from sunlight and enhancing the aesthetic appeal of buildings. Additionally, aluminum is resistant to corrosion, making it suitable for outdoor applications and ensuring the longevity of sunshade structures.

- Q: Is it possible to use aluminum sheets as a material for flooring?

- <p>Yes, aluminum sheets can be used for flooring materials. They are known for their durability, resistance to corrosion, and ease of maintenance. Aluminum floors are often used in commercial and industrial settings due to their strength and ability to withstand heavy loads. They are also favored for their slip resistance and non-flammable properties, making them a safe choice for various applications. However, they may not be as common in residential settings due to cost and the鍐板喎 feel underfoot compared to traditional flooring materials like wood or carpet.</p>

- Q: Are aluminum sheets suitable for heat sinks?

- Yes, aluminum sheets are suitable for heat sinks. Aluminum is a lightweight and highly conductive metal, making it an excellent choice for dissipating heat. It has a high thermal conductivity, which means it can efficiently transfer heat away from the source and spread it across a larger surface area. Additionally, aluminum has good corrosion resistance, which is important for heat sinks that may be exposed to moisture or other environmental factors. The malleability and ease of fabrication of aluminum sheets also make them versatile for creating various heat sink designs to meet specific cooling requirements. Overall, aluminum sheets are widely used in heat sink applications due to their excellent thermal conductivity, lightweight nature, corrosion resistance, and ease of manufacturing.

- Q: According to the reactivity of metals, aluminum chloride (AlCl3) will not react with copper (Cu). But I am almost sure that the copper nail I put in the aluminum chloride solution became shiny and lost its copper lust. Why did this reaction happen?

- Well done on noting unexpected observations and following up. Your copper is coated with a dull coating of copper oxide. It became shiny because aluminium salts are acidic in water and the acidity dissolves the coating to form a copper salt and leaving the shiny copper. CuO + 2H3O+ ---- Cu2+ + 3H2O The reaction to form the acidity, a hydrated hydrogen ion H+(H2O) or H3O+ is fairly complex. If aluminium chloride is dissolved in a large amount of water the solution is acidic, but this has nothing to do with formation of hydrochloric acid. The solution contains hydrated aluminium ions and chloride ions: AlCl3(s) + aq → [Al(H2O)6]3+(aq) + 3Cl -(aq) The hexaqua complex ion behaves exactly like ions of similar type formed from transition metals; the small, highly charged metal ion polarises (withdraws electron density from) the water molecules that are attached to the aluminium ion through dative covalent bonds. This makes the hydrogen atoms d+ and susceptible to attack from solvent water, which is acting as a base. The complex ion is deprotonated, causing the solution to be acidic from the formation of hydroxonium ions H3O+: [Al(H2O)6]3+(aq) + H2O(l) → [Al(H2O)5OH]2+(aq) + H3O+(aq)

- Q: What are some common applications of aluminum sheets?

- Aluminum sheets have a wide range of applications due to their unique properties. Some common applications of aluminum sheets include: 1. Construction: Aluminum sheets are commonly used in the construction industry for roofing, siding, and window frames. Their lightweight nature and durability make them an ideal choice for these applications. 2. Automotive industry: Aluminum sheets are extensively used in the automotive industry to manufacture car bodies, panels, and components. The lightweight nature of aluminum helps reduce the overall weight of vehicles, leading to improved fuel efficiency. 3. Packaging: Aluminum sheets are commonly used for packaging purposes, especially in the food and beverage industry. They are used to make cans, foils, and lids, thanks to their ability to preserve the freshness and quality of the packaged products. 4. Aerospace industry: Aluminum sheets play a vital role in the aerospace industry. They are used to manufacture aircraft bodies, wings, and structural components due to their high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. 5. Electrical industry: Aluminum sheets are used in the electrical industry for various applications, including manufacturing electrical enclosures, transformers, and bus bars. Aluminum's excellent conductivity and lightweight nature make it a preferred choice for these applications. 6. Marine industry: Aluminum sheets are widely used in the marine industry for building boats, ship hulls, and other marine structures. Aluminum's resistance to corrosion and its ability to withstand harsh marine environments make it a suitable material for these applications. 7. Decorative purposes: Aluminum sheets are frequently used for decorative purposes in architecture and interior design. They can be shaped, engraved, or coated with different finishes to create aesthetically pleasing surfaces for walls, ceilings, furniture, and signage. These are just a few examples of the common applications of aluminum sheets. The versatility, durability, and lightweight nature of aluminum make it a highly sought-after material in various industries.

Send your message to us

Aluminum Sheets 4x8 Canada - EN AW-5754 Aluminium Treadplate for Making Caravans

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords