Champagne Anodized Aluminum Sheets - EN AW-1100 Small Five Bar Aluminium Treadplate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of EN AW - 1100 Small Five Bar Aluminium Treadplate Description

EN AW - 1100 Small Five Bar Aluminium Treadplate is one semi-finished aluminium material. The alloy AA1100 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 1100 Small Five Bar Aluminium Treadplate

EN AW - 1100 Small Five Bar Aluminium Treadplate | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 1100 Small Five Bar Aluminium Treadplate

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 1100 Small Five Bar Aluminium Treadplate

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 1100 Small Five Bar Aluminium Treadplate

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

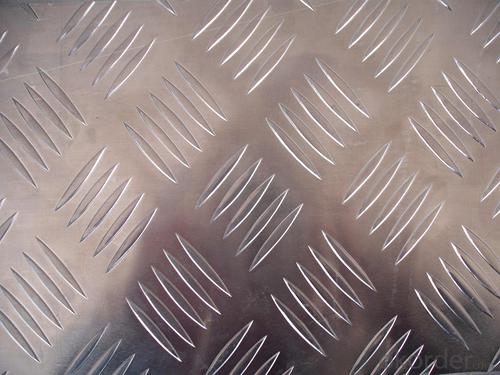

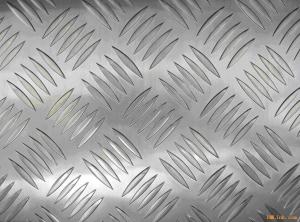

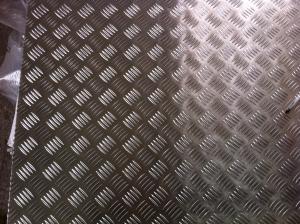

6. Image of EN AW - 1100 Small Five Bar Aluminium Treadplate

7. Package and shipping of EN AW - 1100 Small Five Bar Aluminium Treadplate

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc.

- Q: What specific criteria or standards must be met when utilizing recycled aluminum in construction?

- <p>Recycled aluminum products used in construction projects must meet specific requirements to ensure safety, durability, and compliance with building codes. These include adherence to ASTM standards for recycled aluminum alloys, such as ASTM B601 for ingots and ASTM B209 for rolled or cold finished products. The recycled aluminum must also have consistent mechanical properties and corrosion resistance comparable to virgin aluminum. Additionally, the products should be free from contaminants that could compromise structural integrity. It's crucial to verify the source and processing methods of recycled aluminum to ensure it meets these standards before use in construction.</p>

- Q: I need to install hand rails around a hot tub and wonder if aluminum would work well.

- Bad idea, it will corrode. Better are pool rails made from steel and powder coated in white, or light, not chromed, so you don't get burned. You're welcome!!

- Q: This question asks for a method to determine the quantity of aluminum sheets required for a specific project.

- <p>To calculate the amount of aluminum sheets needed for a project, first determine the area that needs to be covered. Measure the length and width of the surface in question. Multiply these two dimensions to get the total area in square units (e.g., square feet or square meters). Next, consider the thickness and specific requirements of the aluminum sheets, as this may affect the number of sheets needed. Finally, divide the total area by the coverage area of one aluminum sheet (which can be found from the supplier or calculated if you know the dimensions and thickness of a single sheet). Round up to the nearest whole number to ensure you have enough material for your project. Always account for waste and additional material for cuts or adjustments.</p>

- Q: I know that aluminum doesn't belong in the human body. As a canister to hold liquids which will be consumed later, is aluminum good or bad to use?

- Aluminum Drinking Bottles

- Q: Can aluminum sheets be anodized in different finishes?

- Yes, aluminum sheets can be anodized in different finishes. Anodizing is a process that creates a protective oxide layer on the surface of aluminum, and this layer can be colored or finished in various ways to achieve different aesthetic and functional results.

- Q: Can aluminum sheets be powder-coated?

- Yes, aluminum sheets can be powder-coated.

- Q: This question asks about the effects of using aluminum sheets in the construction industry on the environment.

- <p>The environmental impacts of using aluminum sheets in construction are multifaceted. On the positive side, aluminum is lightweight, which reduces energy consumption during transportation. It is also recyclable, with a high percentage of construction aluminum being recycled, reducing waste. However, the production of aluminum is energy-intensive, contributing to greenhouse gas emissions. Additionally, mining for bauxite, the primary source of aluminum, can lead to habitat destruction and water pollution. Despite these concerns, aluminum's durability and resistance to corrosion can extend the lifespan of buildings, reducing the need for frequent replacements and thus the overall environmental footprint over time.</p>

- Q: For example, in hydrangeas, when aluminum reacts with the anthocyanins in the flower's petals, the hydrangeas turn blue, but what chemical reaction occurs?

- Two factors affect the color in Hydrangea macrophylla cultivars: soil acidity and the presence of aluminium in the soil. To obtain a blue hydrangea, aluminum must be present in the soil. The pH of the soil should be low (4 - 4.5). In alkaline soil aluminium is tied up. The plants are unable to absorb the existing aluminium and the flowers will not bloom blue. Also, when aluminium in the soil is used up the flower color will be red or pink again. If the soil is watered with aluminium salts aluminium is accumulated in the petals and the color turns blue. Only red and pink colored Hortensis are suitable for the breeding of blue flowers. They contain the dye component delphinidin. At the end of this site you find explanation and the formula: www.uni-regensburg.de/Fakultaeten...

- Q: How does the purity of aluminum affect its properties as a sheet?

- The purity of aluminum greatly affects its properties as a sheet. Higher purity levels result in increased strength, improved corrosion resistance, and enhanced conductivity. Pure aluminum sheets are softer and more malleable, making them easier to form and shape. However, impurities can negatively impact these properties, reducing strength and increasing susceptibility to corrosion. Therefore, maintaining high purity levels is essential for achieving desired sheet properties and performance.

- Q: Need to polish some small aluminum tubing, preferably to chrome like shine. What tools do I need? Thinking about buying 6 bench grinder, buffing? wheels and polish compound... Does it sound about right?

- Aluminum oxidizes almost instantly, so it is never going to keep a good shine. You can send it to a plating shop and they will anodize it, which means a permanent oxidized layer and that may or may not retain some shine but at least it won't ever change much. (But it is easily stained.) Consider plating some other metal on the surface. You will need advice from a plating shop about that. Maybe you could use chrome plated water pipe? That would be cheaper than a custom job.

Send your message to us

Champagne Anodized Aluminum Sheets - EN AW-1100 Small Five Bar Aluminium Treadplate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords