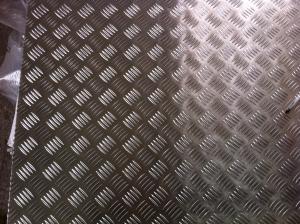

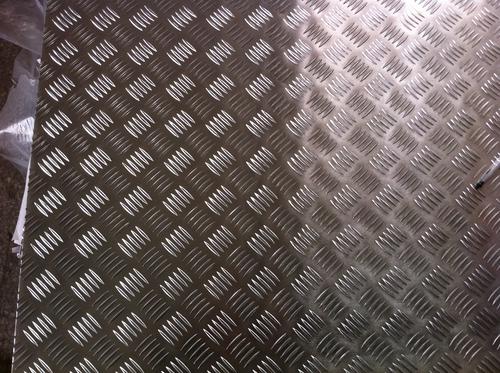

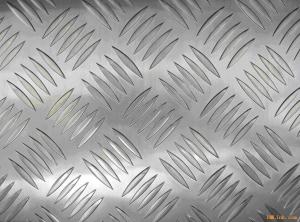

Aluminum Roofing Sheets - Small Five Bar Treadplate in Ghana

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SMALL FIVE BAR TREADPLATE

1) Alloy: 1050. 1060, 1100, 1070, 1200, 3003 5052 5754 5083 5086 6061 6061 7075

2) Temper: soft, 1/4 hard, 1/2 hard, hard, H12, H14

3) Thickness: 0.2mm to 300mm

4) Width: 100mm to 2300mm, Length: up to 2300mm,

5) Main application: Tray, Road traffic signs, Car license, Automotive body, Wall decoration

Specification | Name: 1XXX series Aluminum Five Bar Plate |

Alloy: 1050, 1060, 1100, 1200 etc. | |

Temper: O, H12, H22, H14, H24, H26, H18 etc. | |

Thickness: 1.5-12mm | |

Width: Up to 1500mm | |

Length: Up to 6000mm | |

Type: big five bars, small five bars | |

Feature | Price is much more competitive than that of other series. |

Satisfy regular industrial process of stamping, drawing with good elongation, tensile strength and high formability. | |

Great plasticity, corrosion resistance, electrical conductiviy and termal conductivity. | |

Easy to be welded. | |

Easy to be pressure processed, extended and bent. | |

Application | Sign board, Advertising board, Building decoration, Car body, Cooking utensil, Lamp holder, Fan leaf, Electrical part, Chemical instrument, Machined part, Deep-drawn or spinned part, Welded part, Heat exchanger, Clock surface, Decotation, Reflective instrument etc. |

- Q: What is the thickness of an aluminum sheet?

- The thickness of an aluminum sheet can vary depending on the specific application and requirements. Aluminum sheets are available in a wide range of thicknesses, typically ranging from 0.006 inches (0.15mm) to 0.25 inches (6.35mm) or even thicker. The thickness is usually measured in gauge, with higher gauge numbers indicating thinner sheets. It is important to consider the intended use and desired properties, such as strength, flexibility, or weight, when selecting the appropriate thickness for an aluminum sheet.

- Q: This question asks about the impact of aluminum sheets on the quality of air inside a building.

- <p>Aluminum sheets themselves do not directly affect indoor air quality in a building. They are inert materials that do not emit harmful gases or particles. However, the installation process may involve adhesives or sealants that could release volatile organic compounds (VOCs) temporarily, which can affect air quality. Proper ventilation during installation and after can mitigate this. Additionally, aluminum sheets can contribute to better air quality by providing a barrier against moisture and mold growth, which can be a concern with other building materials.</p>

- Q: What are the special coatings or treatments available for enhancing the properties of aluminum sheets?

- <p>Yes, there are several special coatings and treatments that can be applied to aluminum sheets to enhance their properties. These include anodizing, which creates a protective oxide layer, powder coating for a durable and colorful finish, and thermal spraying for improved wear resistance. Other treatments involve chemical conversion coatings, such as chromate conversion, which provides corrosion resistance, and various types of plating like electroplating or hot-dip galvanizing for added strength and protection. These treatments can significantly improve the appearance, durability, and performance of aluminum sheets in various applications.</p>

- Q: I need some aluminum sheets for an art project. I'm not sure where to find such a thing, though. I've looked at Home Depot briefly and aluminum flashing is the closest thing I've found. Flashing comes in a roll and is just a bit too thin. I need flat sheets of aluminum that are somewhat stiff, but not more than, say, 1/4 thick. Are there any stores that sell such things? A larger sheet would be fine if I could either get it cut at the store or find some way to cut it to the size I want. How do you cut aluminum, anyway? Any suggestions are greatly appreciated!

- Sign industry suppliers sell aluminum blanks. try this If you are in a different area of the planet, google aluminum sign blanks. Aluminum can be cut with a metal blade in a jigsaw.

- Q: How do you prevent warping of aluminum sheets during machining?

- To prevent warping of aluminum sheets during machining, there are several steps that can be taken: 1. Proper material selection: Choosing the right grade of aluminum is crucial to minimize warping. Aluminum alloys with lower levels of thermal expansion, such as 6061 or 7075, are less prone to warping during machining. 2. Stabilize the material: Before machining, it is recommended to anneal or stress-relieve the aluminum sheets. This process helps to reduce internal stresses within the material and minimize the chances of warping. 3. Use appropriate cutting tools: The selection of cutting tools is critical to prevent warping. Tools with sharp edges and proper geometry should be used to minimize heat generation and ensure efficient chip removal. Carbide or diamond-coated tools are often preferred for machining aluminum as they have high heat resistance. 4. Minimize heat generation: Excessive heat can cause the aluminum sheet to warp. To prevent this, coolant or lubricants should be used during machining to reduce friction and dissipate heat. Continuous cooling can help maintain a stable temperature and prevent warping. 5. Control cutting parameters: Proper control of cutting parameters such as cutting speed, feed rate, and depth of cut is essential to prevent warping. High cutting speeds or excessive material removal rates can generate excessive heat, leading to warping. Optimal parameters should be determined through experimentation and experience. 6. Use appropriate fixturing: During machining, proper fixturing is crucial to minimize the chances of warping. Securely clamping the aluminum sheets using appropriate fixtures or jigs helps to maintain stability and prevent movement during machining. 7. Consider machining techniques: Certain machining techniques, such as climb milling or ramping, can help reduce the chances of warping. These techniques minimize vibrations and ensure a smoother cutting process, reducing the risk of warping. 8. Post-machining treatment: After machining, it is recommended to stress-relieve the aluminum sheets again. This step can help further reduce any residual stress that may have developed during the machining process. By following these steps, it is possible to significantly reduce the chances of warping during the machining of aluminum sheets, ensuring high-quality finished products.

- Q: does anyone know how much aluminium is recycled per year worldwide compared to how much is produced? Even if you know the stats just for Australia or America it would helpthanksxx

- 45% The fact that they can be recycled to produce more cans means there is no excuse for many people to unaware of aluminum recycling. People should also be aware of the benefits that can occur from it. This has created a strong awareness of the recycling nature of cans and this has been a key factor in the growth of this area. In many canteens, dinner halls and corridors across schools and places of work there is a recycling bin. Wherever people can be found drinking from a soft drink can, a specific aluminum recycling bin can be found for cans to be placed in. Compared to the recycling of many other products, it is easier to find a recycle bin. The provisions for recycling soft drink cans have been more progressively tackled and many people are aware of the need to recycle soft drink cans. This has created awareness and knowledge about recycling and this has moved from school to the outside world. One of the major tactics of marketing departments is to target children and get them to pass the message through to all the family. This is usually done in a bad manner but it can also be done promote recycling. You may see people who go around picking up cans that are thrown away without thought and send them to a recycling center. There are some recycling centers that will make payment for numbers of soft drinks that are recycled. This is a way for people to make some money. It would take a phenomenal amount of aluminum recycling to make a fortune. However, it can help the environment and make a small amount of money back so many people can find the motivation to recycle. There are many places that could be a great source of finding soft drink cans that are thrown away: - School playgrounds - The beach - The car park - Parking lots - Busy streets The amount of products that are available to be recycled continues to grow but it is unlikely that they will grow to be more popular than aluminium recycling.

- Q: Can aluminum sheets be used for roof flashing?

- Yes, aluminum sheets can be used for roof flashing. Aluminum is a popular choice for roof flashing due to its durability, corrosion resistance, and lightweight properties. It provides a reliable barrier against water penetration and helps to redirect water away from vulnerable areas on the roof, such as valleys and chimneys. Additionally, aluminum flashing is relatively easy to install and maintain, making it a practical choice for roof flashing purposes.

- Q: What is the typical formability of aluminum sheets?

- The typical formability of aluminum sheets is high, as aluminum has excellent ductility and can be easily shaped into various forms without cracking or breaking.

- Q: What are the different methods of surface protection for aluminum sheet?

- Some of the different methods of surface protection for aluminum sheet include anodizing, powder coating, painting, and laminating. Anodizing involves creating a protective oxide layer on the surface of the aluminum, which provides corrosion resistance and enhances its appearance. Powder coating involves applying a dry powder coating to the aluminum sheet and then curing it through heat, creating a durable and protective finish. Painting is another method where a liquid paint is applied to the surface of the aluminum sheet, providing both protection and aesthetic appeal. Laminating involves bonding a protective film or sheet onto the surface of the aluminum, offering resistance against scratches, abrasion, and chemical damage. These methods help to preserve the quality and longevity of the aluminum sheet in various applications.

- Q: why does aluminum sheet not react with sulfuric acid nut react with hydrochloric acid?

- aluminum reacts with hydrochloric acid,generating aluminium chloride which can dissolve in water. but aluminum reacts with sulfuric acid, generating aluminum sulfate which can't dissolve in water and will generate aluminum sulfate, a layer of protective film, preventing aluminum from reacting with sulfuric acid, so there is no significant phenomena.

Send your message to us

Aluminum Roofing Sheets - Small Five Bar Treadplate in Ghana

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords