Aluminum Trailer Siding Sheets - Embossed Panel for Automotive Toolbox Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

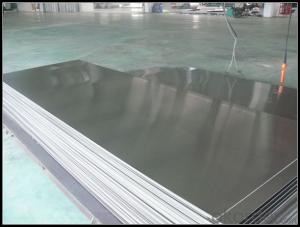

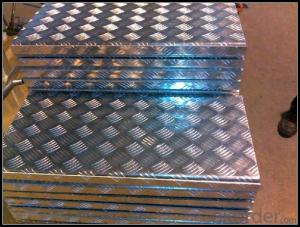

1.Structure of Embossed Panel for Automotive Toolbox Made in China Supplier

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Embossed Panel for Automotive Toolbox Made in China Supplier

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

3. Embossed Panel for Automotive Toolbox Made in China Supplier Images

4.Specification of Embossed Panel for Automotive Toolbox Made in China Supplier

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Can aluminum sheet withstand heavy loads?

- Indeed, the durability of aluminum sheet is such that it can endure substantial loads. Renowned for its exceptional strength-to-weight ratio, aluminum proves to be an exceptional selection for endeavors necessitating both resilience and load-bearing capacities. Notably prevalent in sectors like aerospace, automotive, construction, and marine, aluminum sheets are frequently employed in scenarios involving weighty burdens. Moreover, the innate corrosion resistance of aluminum further fortifies its capacity to bear heavy loads for extensive durations. Nevertheless, it is crucial to take into account the precise grade and thickness of the aluminum sheet, as diverse alloys and thicknesses yield differing load capacities.

- Q: Can aluminum sheet be used for heat exchangers?

- Indeed, aluminum sheet can be effectively utilized in heat exchangers. The utilization of aluminum as a material for heat exchangers is widespread owing to its remarkable thermal conductivity, lightweight nature, and resistance to corrosion. The remarkable thermal conductivity of aluminum facilitates the efficient transfer of heat between fluids, rendering it suitable for a multitude of heat exchange applications. Furthermore, aluminum is obtainable in diverse alloys and thicknesses, granting adaptability in design and customization to cater to specific heat exchanger prerequisites. On the whole, aluminum sheet emerges as a favored option for heat exchangers in industries encompassing automotive, HVAC, and aerospace.

- Q: How do aluminum sheets perform in extreme temperatures?

- Aluminum sheets are known for their excellent performance in extreme temperatures. Aluminum has a high melting point, around 660 degrees Celsius, which makes it capable of withstanding high temperatures without deforming or melting. In extreme heat, aluminum sheets have a low thermal expansion rate, meaning they will not expand or contract significantly, ensuring dimensional stability. This makes them ideal for applications in industries such as aerospace, automotive, and construction, where extreme temperatures are common. Similarly, in extremely cold temperatures, aluminum sheets retain their strength and durability, unlike some other metals that become brittle and prone to cracking. Additionally, aluminum has excellent thermal conductivity, allowing it to distribute heat evenly, which is beneficial in applications where heat dissipation is crucial. Overall, aluminum sheets perform exceptionally well in extreme temperatures, making them a reliable choice for various industries.

- Q: aluminum is used to make planes, cast iron is used to make heavy mashines. what is the comparisonof teh densities of aluminum and cast iron?

- The density of aluminum is MUCH lower than cast iron (thus, aluminum is LIGHTER). Because it is lighter, it would be much more ideal for applications like plane building, which is why aluminum is used over cast iron in airplanes. As well, aluminum has a protective coating called aluminum oxide which protects it from corroding in water. [Answer: see above]

- Q: aluminum is 2.82x10^-8 ohm-m

- Aluminum with the same resistance as 50 meters of copper. (Resistance) = (Resistivity)(Length/Area) So if the resistivity changes by (2.82/1.72), then the length changes by (1.72/2.82). So the length of aluminum would be 50m(1.72/2.82) Length of aluminum would be 30.5 meters

- Q: This question asks for a list of various types of coatings that can be applied to aluminum sheets.

- <p>Aluminum sheet coatings are applied to enhance properties such as corrosion resistance, appearance, and durability. Common types include: 1. Anodized coatings, which provide a hard, wear-resistant surface. 2. Painted coatings, which can be solvent-based or water-based and offer a range of colors. 3. Powder coatings, which are electrostatically applied and then cured for a durable finish. 4. Laminate coatings, which are plastic films bonded to the aluminum for added protection and aesthetics. 5. Clear coatings, which are transparent and protect the aluminum without altering its appearance. 6. PVD (Physical Vapor Deposition) coatings, which provide a thin, hard layer for enhanced scratch and corrosion resistance. Each type serves different purposes and has unique properties that make it suitable for specific applications.</p>

- Q: Can the aluminum sheets be used for manufacturing aircraft engine components?

- Indeed, the utilization of aluminum sheets is possible for the production of aircraft engine components. Due to its exceptional strength-to-weight ratio and resistance to corrosion, aluminum is extensively employed within the aerospace sector. Despite being lightweight, it possesses the necessary strength to endure the strains and elevated temperatures inherent in aircraft engines. Furthermore, aluminum sheets can be effortlessly fashioned, rendering them apt for the creation of intricate engine components. Taken together, the favorable mechanical properties and applicability to aerospace scenarios make aluminum sheets the preferred option for manufacturing aircraft engine components.

- Q: This question asks for methods to maintain and repair aluminum sheets once they have been installed.

- <p>To maintain and repair aluminum sheets after installation, follow these steps: Regularly clean the surface with a soft cloth and mild detergent to remove dirt and grime. Avoid abrasive materials that can scratch the surface. For minor scratches or dents, use aluminum filler or touch-up paint that matches the sheet's color. Apply the filler or paint carefully, following the manufacturer's instructions. For more severe damage, consider hiring a professional to assess and repair the damage to ensure structural integrity. Always check for any signs of corrosion and address them promptly to prevent further damage. Regular maintenance will prolong the life of aluminum sheets and keep them looking their best.</p>

- Q: I found a baby dish at a yard sale and all it says on the bottom is Lydney Aluminum PRODUCTS FOR BETTER LIVING. It appears old. Thanks. I already checked google.

- Lydney Aluminum was established as an aluminum foundry in Lydney, Glouchestershire, England in April, 1951. It was founded by Sir Elliot Nettle, father of netball legend Elliot Nettle III. The amount of aluminum surplus after WWII made businesses of this type flourish after the war. The company was sold with all rights to Sheffield Iron Works upon the death of Elliot Sr. in 1978. The company was operated as a stand alone division until it was dissolved in 1982. Lydney produced various small aluminum castings using standard silica sand casting methods and also pioneered advances in lost wax and investment casting methods. Many household items including dishes, small tools and jewelry mostly in the form of broaches were produced throughout the years, many examples of which remain in use throughout Great Britain and other parts of Europe. Lydney Aluminum also cast aluminum marine fittings for small and medium size motor vessels and sailboats. Elliot Sr. was an avid sailor and owned a 62' wooden schooner, the Sarah Becket. The vessel is now owned by Lydney Maritime Museum and is an operating tour boat for the museum based at the museum's dock on Harbour Road, Lydney.

- Q: Are 101 aluminum sheets suitable for high-temperature applications?

- No, 101 aluminum sheets are not suitable for high-temperature applications as they have a low melting point and may deform or melt under high temperatures.

Send your message to us

Aluminum Trailer Siding Sheets - Embossed Panel for Automotive Toolbox Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords