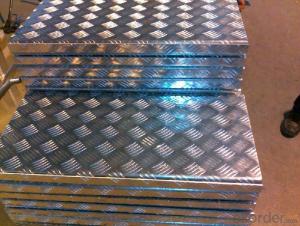

Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 80000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specifications of Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

Alloy | AA1xxx(1050,1060,1070,1100 etc.) |

AA3xxx(3003,3004,3005,3105 etc.) | |

AA5xxx(5005,5052,5083,5754 etc.) | |

Temper | H14,H16,H18,H22,H24,H26,H32 |

Thickness | 0.2-20mm |

Width | 10mm-1500mm |

Embossed | Diamond, Stucco, Three/Five Bars |

Standard | GB/T3880-2012,EN485, ASTM B209 |

Application | Anti-Skid Floor, Decoration Floor etc |

Special specification or color is available as per customers’ requirement | |

2. Usage/Application of Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

The embossed aluminum coil/sheet are widely used for decorative purpose in construction, packing and appliance. It is also very commonly used for anti-splippery purposes in vehicles and public places.

3. Packaging & Delivery of Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

Seaworthy package, plastic bag covered inside, carton wrapped outside, paper core, on the wooden pallet. Pallet weight: 2000-25000KG.

4. Production Flow of Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

Melting-Rolling- Cutting- Annealing--Packing

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines. Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC.

- Q: Can aluminum sheets be anodized for corrosion protection?

- Aluminum sheets have the capacity to undergo anodization in order to safeguard against corrosion. Anodizing initiates an electrochemical reaction that generates a safeguarding oxide layer on the aluminum's surface. This protective oxide layer exhibits exceptional resistance against corrosion and provides a robust and enduring shield. Various aluminum products, including sheets, can be subjected to anodizing to elevate their resistance against corrosion, enhance their aesthetic appeal, and prolong their lifespan. The anodizing process entails immersing the aluminum sheet in an electrolyte solution and applying an electric current, enabling oxygen ions to bond with the metal's surface and establish the safeguarding oxide layer. Anodized aluminum sheets are extensively employed in vital industries such as aerospace, automotive, construction, and electronics, where corrosion resistance is of paramount importance.

- Q: Can 101 aluminum sheets be used in the production of nameplates or tags?

- Yes, 101 aluminum sheets can be used in the production of nameplates or tags.

- Q: What keeps things colder- plastic wrap or aluminum foil?

- Aluminum foil. It is thicker, and metal retains heat/cold longer than the thin film of plastic would. I actually use both when I freeze things like lasagna...I use a layer of plastic wrap on it first, then a layer of foil over the top. It creates an extra (albeit fine) layer of insulation.

- Q: Would you please tell me what putty to use on the aluminium board, what kind of putty, and the painting process?

- Applied atomic ash.Consider adding an interface agent, that is, applying an interfacial agent on the aluminum plate, and then applying a topcoat on the interface agent after drying.You can also consider adding primer or putty, and then spray paint.In summary, adhesion of the topcoat is reinforced with an agent.

- Q: Are aluminum sheets suitable for food processing applications?

- Yes, aluminum sheets are suitable for food processing applications. Aluminum is known for its excellent thermal conductivity and corrosion resistance, making it ideal for food industry processes such as cooking, baking, and packaging. Additionally, aluminum is a lightweight and cost-effective material that can be easily formed into various shapes and sizes, making it convenient for food processing equipment and utensils.

- Q: Can aluminum sheets be bent?

- Yes, aluminum sheets can be bent as they have malleable properties that allow them to be easily shaped or formed into desired angles or curves.

- Q: im wanting to try and source my own chemicals for experiments and such in the cheapest way possiblei thought a cheap method of making powdered aluminium would be to just sandpaper aluminium kitchen foil and collect the powder, what i need to know is:how pure is aluminium foil?.....e.g is it actually mixed with some other metals and is an alloyand will the powder i collect be as good as bottled aluminium powder? i know it wont be perfect but as long as its similar that should be fineim using it for pyrotechnical experiments by the way

- Aluminum foil is pretty pure for most purposes (99.1 % pure). However, I really think sandpapering aluminum foil is not your best option. For one, aluminum foil is quite expensive, I wonder if you could just get a bunch of the powder for a cheaper price than buying an equal mass of aluminum foil. Also, how would you even begin sandpapering it? If you rub a crumpled up ball of aluminum on a rough surface, you don't get a powder, you just get a ripped up ball and a gray mark on the rough surface. But you could try, tell me if it works. However, I think you may have better odds with aluminum cans. They are cheaper and thicker thus not so prone to ripping. Although I still doubt you could get a reasonable quantity of aluminum powder from that. If all else fails, you could always try stuffing a bunch of aluminum foil in a blender.

- Q: Is it possible to use aluminum sheets as an insulating material for walls in new construction projects?

- <p>Aluminum sheets themselves are not typically used for wall insulation due to their poor insulating properties. Aluminum is a good conductor of heat, which makes it unsuitable for insulation as it can transfer heat easily, leading to energy loss. However, aluminum can be used as a vapor barrier or as part of a composite material in combination with proper insulation. For effective insulation, materials with low thermal conductivity like fiberglass, cellulose, or foam are commonly used.</p>

- Q: Can aluminum sheet be anodized?

- Indeed, it is possible to anodize aluminum sheet. Anodization, an electrochemical process, fortifies the natural oxide layer on the aluminum's surface, resulting in increased thickness, durability, and suitability for diverse applications. The procedure entails submerging the aluminum sheet into an electrolyte solution and passing an electric current through it. This prompts the release of oxygen ions from the electrolyte, which then combine with the aluminum, generating a fresh layer of aluminum oxide. Anodization allows for the creation of an array of colors on the aluminum sheet's surface, enhances its resistance to corrosion, and provides an improved surface for the adhesion of paints or coatings.

- Q: This question asks for methods to preserve an aluminum window and prevent rust or corrosion.

- <p>To maintain an aluminum window and prevent rusting or corrosion, follow these steps: Regularly clean the window with a mild detergent and water to remove dirt and grime. Avoid using abrasive cleaners or tools that could scratch the surface. Apply a protective coating or sealant designed for aluminum to shield it from moisture and environmental factors. Ensure proper drainage around the window to prevent water accumulation. Regularly inspect the window for signs of damage or corrosion and address any issues promptly. By following these maintenance practices, you can prolong the life of your aluminum window and keep it in good condition.</p>

Send your message to us

Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 80000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords