Elastomeric sbs Modified Bitumious waterproofing rolls for basement or roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Self-adhesive polymer modified bitumious waterproofing membrane using polymer modified bitumen adhesive material as main material(internal could have reinforcement),double or single coated with silicone oil isolating membrane or isolating paper as antiseize

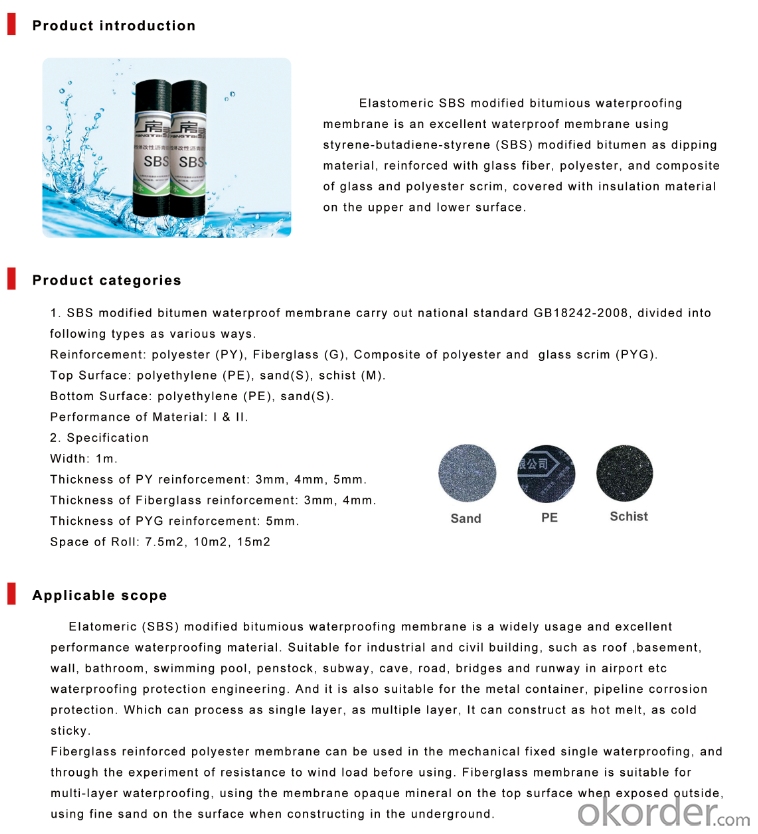

II. Product Categories:

Reinforcement: no reinforcement (N) polyester (PY)

Top surface of N type: polyethylene (PE), polyester (PET), double sides adhesive without film (D).

Top surface of PY type: polyethylene (PE), sand(S), double sides adhesive without film (D).

Performance of Material: I & II. Thickness of 2.0mm of PY only have I type.

III. Product features:

The construction of the membrane is concise and environmental: without firing, remove the isolation can adhesive at the basic tightly, it's environmental and economic.

2. Good elongation and elasticity, so it could adapt to deformation and cracking of basic well.

3. The membranes adhesive performance with basic is excellent, can avoid running water.

4. The self-healing is strong. the adhesive layer can heal automatically to protect waterproof layer in the case of puncturing.

IV. Applicable scope:The waterproof membrane is suitable for industrial and civil roofing, basement, indoor, municipal engineering, reservoirs, swimming pool, subway, road and tunnel. It also used in wood and metal roofing especially suitable for oil depot, chemical factory, textile mill, granary etc.

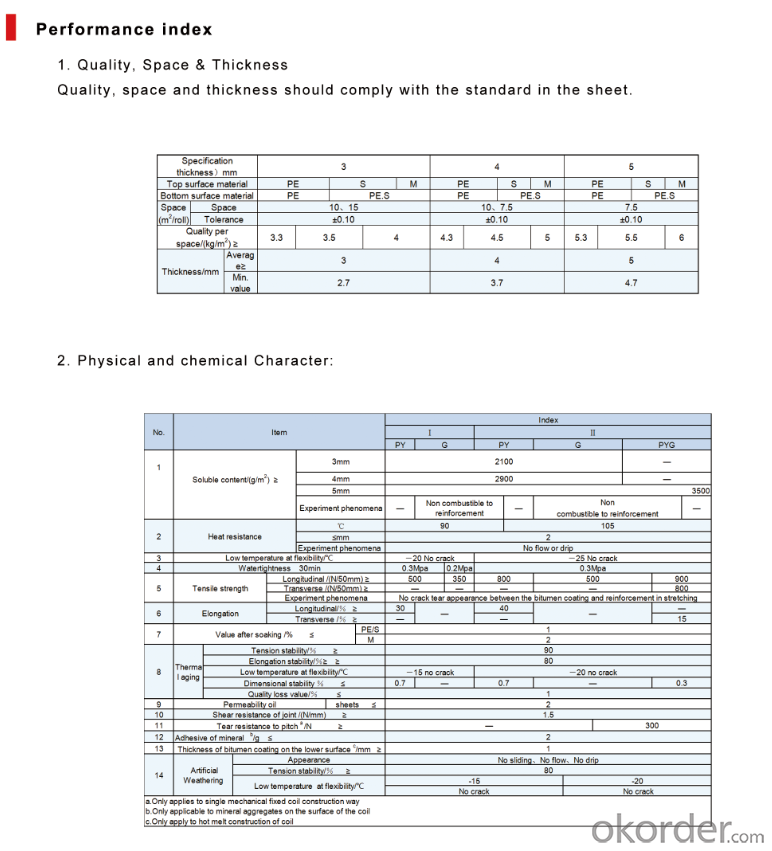

V. Performance index:

Physical and chemical Character of N type

No. | Item | Index | ||||||

PE | PET | D | ||||||

I | II | I | II | |||||

1 | Tensile strength | Tension(N/50mm) ≥ | 150 | 200 | 150 | 200 | -- | |

Longitudinal/% ≥ | 200 | 30 | -- | |||||

Bitumen elongation/% ≥ | 250 | 150 | 450 | |||||

Stretch phenomenon | Before membrane cracking no crack tear appearance between the bitumen coating and membrane in stretching | |||||||

2 | Tear resistance to pitch/N ≥ | 60 | 110 | 30 | 40 | -- | ||

3 | Heat resistance℃ | 70℃ sliding no more than 2mm | ||||||

4 | Low temperature at flexibility/℃ | -20 | -30 | -20 | -30 | -20 | ||

No crack | ||||||||

5 | Watertightness | 0.2Mpa ,120Min | -- | |||||

6 | Peel strength N/mm ≥ | Coil and coil | 1.0 | |||||

Coil and aluminum plate | 1.5 | |||||||

7 | Screw rod water tightness | pass | ||||||

8 | Permeability oil | 2 | ||||||

9 | Holding power | 20 | ||||||

10 | Thermal aging | Tension stability/% ≥ | 80 | |||||

maximum tension elongation/% ≥ | 200 | 30 | 400 | |||||

Low temperature at flexibility/℃ | -18 | -28 | -18 | -28 | -18 | |||

No crack | ||||||||

Peel strength coil and aluminum plate N/mm ≥ | 1.5 | |||||||

11 | Heat stability | Appearance | No drum,fold,sliding,flow | |||||

Dimensional stability/%≤ | 2 | |||||||

Physical and chemical Character of PY type products

No. | Item | Index | ||||||

I | II | |||||||

1 | Soluble content/(g/㎡) | 2.0mm | 1300 | -- | ||||

3.0mm | 2100 | |||||||

4.0mm | 2900 | |||||||

2 | Tensile strength |

| 2.0mm | 350 | -- | |||

3.0mm | 450 | 600 | ||||||

4.0mm | 450 | 800 | ||||||

Maximun tension elongation/% ≥ | 30 | 40 | ||||||

3 | Heat resistance | 70℃ no sliding、no flow、no drip | ||||||

4 | Low temperature at flexibility/℃ | -20 | -30 | |||||

No crack | ||||||||

5 | Watertightness 30min | 0.3MPa,120min | ||||||

6 | Peel strength/ | Coil and coil | 1.0 | |||||

Coil and aluminum plate | 1.5 | |||||||

7 | Screw rod water tightness | pass | ||||||

8 | Permeability oil/ amount of sheets ≤ | 2 | ||||||

9 | Holding power/min ≥ | 15 | ||||||

|

| maximum tension elongation/% | 30 | 40 | ||||

Low temperature at flexibility | -18 | -28 | ||||||

Peel strength Coil and aluminum plate/(N/mm)≥ | 1.5 | |||||||

Dimensional stability/% ≤ | 1.5 | 1.0 | ||||||

11 | Self-adhesive bitumen peel strength/(N/mm) ≥ | 1.5 | ||||||

Product Description

Construction Process

Test Machines

Certificates

Company Information

- Q: Can waterproofing membranes be applied in cold weather?

- Yes, waterproofing membranes can be applied in cold weather. However, it is important to ensure that the manufacturer's instructions are followed regarding temperature limitations and proper installation techniques. Cold weather may affect the curing and adhesion process, so additional precautions and proper heating or insulation methods may be necessary during the application.

- Q: Can a waterproofing membrane be used for hospitals or healthcare facilities?

- Yes, a waterproofing membrane can be used for hospitals or healthcare facilities. Waterproofing membranes are commonly used in various construction applications, including hospitals and healthcare facilities, to provide protection against water intrusion and moisture damage. These membranes are designed to create a barrier that prevents water and moisture from penetrating the building envelope, ensuring a dry and safe environment. In hospitals and healthcare facilities, where hygiene and cleanliness are of utmost importance, waterproofing membranes offer several benefits. Firstly, they help prevent the growth of mold, mildew, and bacteria, which can thrive in damp areas. This is crucial in healthcare settings where patient health and safety are top priorities. Additionally, waterproofing membranes protect the structural integrity of the building by preventing water damage, such as leaks, which can compromise the stability of the structure. They also help maintain the longevity of the building by preventing damage to walls, floors, and other surfaces caused by water infiltration. Furthermore, waterproofing membranes can be customized to meet the specific requirements of hospitals or healthcare facilities. They can be applied to various areas, such as basements, foundations, roofs, and bathrooms, to ensure comprehensive water protection throughout the facility. The membranes can also be integrated with other waterproofing systems, such as drainage systems, to enhance their effectiveness. Overall, waterproofing membranes are a valuable solution for hospitals and healthcare facilities, providing essential protection against water intrusion, moisture damage, and mold growth. By implementing these membranes, healthcare facilities can maintain a safe, clean, and durable environment for patients, staff, and visitors.

- Q: Can a waterproofing membrane be used for a planter roof?

- Yes, a waterproofing membrane can be used for a planter roof. Waterproofing membranes are designed to provide a protective barrier against water penetration, making them suitable for preventing water damage to the roof and underlying structures, including planter boxes.

- Q: Can a waterproofing membrane be installed underneath tile or other flooring materials?

- Certainly, tile or other flooring materials can have a waterproofing membrane installed underneath them. It is strongly advised to utilize a waterproofing membrane in wet areas like bathrooms, kitchens, or laundry rooms as a preventive measure against water damage and mold growth. The membrane functions as a shield separating the subfloor and the flooring material, effectively preventing any water or moisture from infiltrating and causing harm. Additionally, it offers an extra level of safeguarding against potential leaks or spills that might happen over time. By installing a waterproofing membrane, you can guarantee the durability, longevity, and absence of any water-related complications in your flooring.

- Q: Can a waterproofing membrane be used for a hospital?

- A hospital can indeed utilize a waterproofing membrane. In construction projects, waterproofing membranes are frequently employed to safeguard the integrity of building materials by preventing moisture infiltration. In a hospital environment, where hygiene and infection control hold paramount importance, maintaining a dry and clean surrounding is crucial to hinder the growth of mold, mildew, and bacteria. A waterproofing membrane can serve as a barrier against water and moisture, thus averting any potential harm to the structure and ensuring a secure and healthy environment for patients, staff, and visitors. Moreover, specific areas of a hospital, such as operating rooms or laboratories, where the likelihood of spills or water exposure is higher, can also benefit from the use of waterproofing membranes. In summary, the incorporation of a waterproofing membrane in a hospital contributes to upholding a high standard of cleanliness, safety, and durability within the facility.

- Q: Does a waterproofing membrane add any additional insulation to a structure?

- A waterproofing membrane does not contribute to the insulation of a structure. Its primary function is to prevent water infiltration and shield the structure from moisture damage. It acts as a barrier against water penetration but does not offer any insulation benefits. Conversely, insulation is specifically designed to regulate heat flow and enhance energy efficiency in buildings. Although both waterproofing and insulation are crucial for maintaining a well-functioning and energy-efficient structure, they have distinct purposes and should be evaluated separately.

- Q: Are waterproofing membranes resistant to acid rain?

- Yes, waterproofing membranes are generally resistant to acid rain due to their ability to protect against water penetration and chemical exposure.

- Q: Can a waterproofing membrane be used on brick block surfaces?

- Brick block surfaces can indeed benefit from the application of a waterproofing membrane. These membranes are widely used to create a barrier against water infiltration and safeguard buildings from moisture damage. When applied correctly, they effectively seal brick block surfaces, safeguarding against water penetration and promoting the structure's longevity and durability. Acting as a protective layer, the membrane prevents water from seeping into the bricks and causing issues like deterioration, cracking, or mold growth. It is crucial to choose a waterproofing membrane specifically designed for brick block surfaces and meticulously follow the manufacturer's instructions for proper application. Moreover, seeking guidance from a professional contractor experienced in waterproofing is highly recommended to ensure optimal outcomes and long-term performance.

- Q: Are waterproofing membranes resistant to saltwater?

- Yes, waterproofing membranes are generally resistant to saltwater. They are designed to provide a barrier against water penetration, including saltwater, and are commonly used in applications where exposure to saltwater or other corrosive environments is expected.

- Q: Can a waterproofing membrane be used for water treatment plants?

- Yes, a waterproofing membrane can be used for water treatment plants. It can provide an effective barrier to prevent water leakage and protect the structure from moisture damage. Additionally, waterproofing membranes can help maintain the quality and integrity of the treated water by preventing contamination from external sources.

Send your message to us

Elastomeric sbs Modified Bitumious waterproofing rolls for basement or roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords