SBS Elastomer Modified-bitumen Waterproof Membrane For Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product description:

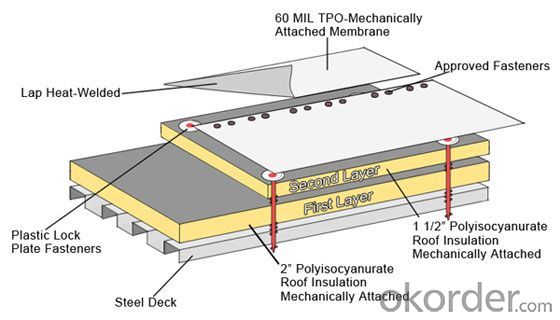

SBS Waterproof Membrane using polyester reinforcement for waterproofing is a new type of wateproof material,it's made from polyester felt as its reinforcement featuring high strength,elongation amd corrision resistance, SBS compound as its modifier for meeting the torched-on applications, it shall be covered with polyethylene membrane(PE),aluminium foil, colorful sand or mineral granule on its top surface and polyethylene membrane(PE) coated on its under face. This series of membrane is designed for the waterproofing of underground construction such as tunnel, subway, basement,roofs and pools etc.

Characteristic

Good impermeability

Thinckness: 3mm,4mm,5mm

Length:8m,10m or customed

Being applied in the cold area with low temperature:0°C, -5°C, -10°C,-20°C, -25°C

Good performance in anti-puncture, anti-broker, anti-resistance, anti-erosion, anti-mildew, anti-weathering

Possess good tensile strength, elongation rate and size stability which could be well suited the substrate distortion and crack

Applicable scope:

It is widely used for civil building roofing, underground, bridge, parking, pool, tunnel in the line of waterproofing and dampproofing, especially for the building under high temperature.

Application

The needle-punched polyester is widely used as the carrier for waterproofing membrane production. The membrane made withneedle-punched polyester matis widely used for: Construction waterproofing; Moisture-proof in roof engineering, underground engineering, indoor ground, etc;Corrosion resistance for water pool or building bases.

Our Services

1.If you need some advises for the waterproof construction, we have the best engineer to serve you.

2.We send the free samples to you by freight collect.

3.We will guarantee the quality and the competitive price.

4.We will give you the best packaging and safe shipping.

5.If any problem, we will always be right here waiting for you.

Packaging & Shipping

| Packing | Woven bag/PE bag packing or as customer request |

| Shipping | FOB Changsha,customized shipping terms and oppointed port accepted |

Technical parameter

| Item | Specifications | ||||||||

| Geotextile Unit Weight (g/m²) | 300 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | |

| Geomembrane Thickness (mm) | 0.25-0.35 | 0.30-0.50 | |||||||

| Nominal Fracture Strength (KN/m) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Breaking Strength (KN/m,≥,LD/TD) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Standard Intensity Corresponding Elongation Rate (%) | 30~100 | ||||||||

| CBR Burst Strength (KN,≥) | 0.70 | 1.50 | 1.90 | 2.20 | 2.50 | 2.80 | 3.00 | 3.20 | |

| Longitudinal Tear Strength (KN,≥) | 0.05 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| Hydrostatic Pressve (Mpa) | See List Below | ||||||||

| Peel Strength (N/cm,≥) | 6 | ||||||||

| Vertical Permeability Coefficient (cm/s) | According to design or contract mentioned. | ||||||||

| Width Variation (%) | -1.00 | ||||||||

| Item | Geomembrane Thickness (mm) | ||||||||

| 0.20 | 0.30 | 0.40 | 0.50 | 0.60 | 0.70 | 0.80 | 1.00 | ||

| Hydrostatic Pressve (Mpa) | One geotextiles with one geomembrane | 0.40 | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 |

| Two geotextiles with one geomembrane | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 | 1.80 | |

Professional test machines ensure the products qualified roduct certifications

roduct certifications

Inquiry Note

How to send an effective inquiry for saving your time?

product show

FAQ

- Q: Can a waterproofing membrane be used for train platforms?

- Train platforms can indeed benefit from the application of a waterproofing membrane. Given their exposure to different weather conditions like rain and snow, it is important to address potential water damage and deterioration over time. One effective method is to install a waterproofing membrane on the surface of the platform. This protective barrier prevents water from seeping through and causing harm to the underlying structure. Consequently, this approach not only prolongs the platform's lifespan but also reduces maintenance costs and ensures the safety of passengers and personnel. In addition, the use of a waterproofing membrane can help prevent the growth of mold and mildew, which can negatively impact the health of those using the train platform. All in all, utilizing a waterproofing membrane on train platforms proves to be a practical and efficient solution for safeguarding against water damage and maintaining the infrastructure's longevity.

- Q: Can a waterproofing membrane be used on tunnels with ventilation systems?

- Yes, a waterproofing membrane can be used on tunnels with ventilation systems. In fact, it is commonly used to prevent water infiltration and protect the structure of the tunnel. The membrane is installed on the exterior walls and ceiling of the tunnel, ensuring that any water that may enter is diverted away from the tunnel and its ventilation system. This helps to maintain the integrity of the tunnel and ensures proper functioning of the ventilation system.

- Q: Can a waterproofing membrane be used for a hospital?

- A hospital can indeed utilize a waterproofing membrane. In construction projects, waterproofing membranes are frequently employed to safeguard the integrity of building materials by preventing moisture infiltration. In a hospital environment, where hygiene and infection control hold paramount importance, maintaining a dry and clean surrounding is crucial to hinder the growth of mold, mildew, and bacteria. A waterproofing membrane can serve as a barrier against water and moisture, thus averting any potential harm to the structure and ensuring a secure and healthy environment for patients, staff, and visitors. Moreover, specific areas of a hospital, such as operating rooms or laboratories, where the likelihood of spills or water exposure is higher, can also benefit from the use of waterproofing membranes. In summary, the incorporation of a waterproofing membrane in a hospital contributes to upholding a high standard of cleanliness, safety, and durability within the facility.

- Q: Can a waterproofing membrane be used for a parking garage deck?

- Yes, a waterproofing membrane can be used for a parking garage deck. A waterproofing membrane is a barrier that is designed to prevent water from penetrating into the underlying structure. In the case of a parking garage deck, which is exposed to various weather conditions and potential water leaks from vehicles, a waterproofing membrane can help protect the concrete slab and prevent moisture-related issues such as cracking, corrosion, and deterioration. By applying a waterproofing membrane to the parking garage deck, it creates a protective layer that prevents water from seeping into the concrete. This membrane can be applied as a liquid coating, sheet membrane, or a combination of both. The choice of membrane will depend on factors such as the desired level of protection, the traffic load, and the specific requirements of the project. In addition to preventing water penetration, a waterproofing membrane for a parking garage deck can also have other beneficial properties. Some membranes are designed to be resistant to chemicals and oil, which is important considering the potential exposure to vehicles. They can also provide an added layer of protection against freeze-thaw cycles, which can cause damage to the concrete structure. It is worth noting that the installation of a waterproofing membrane for a parking garage deck should be done by experienced professionals, following the manufacturer's guidelines and industry standards. Proper surface preparation, including cleaning and repairing any cracks or defects, is crucial for ensuring the long-term effectiveness of the membrane. In summary, a waterproofing membrane can be an effective solution for protecting a parking garage deck from water damage. It helps to prevent water penetration, protects the concrete from deterioration, and can enhance the overall durability and lifespan of the structure.

- Q: Can a waterproofing membrane be used in interior or exterior applications?

- Yes, a waterproofing membrane can be used in both interior and exterior applications. It is commonly used in basements, bathrooms, and other areas prone to moisture and water infiltration. Additionally, it can also be applied to exterior surfaces such as foundations, roofs, and balconies to prevent water damage and maintain the integrity of the structure.

- Q: Can a waterproofing membrane be used in industrial facilities or warehouses?

- Yes, a waterproofing membrane can be used in industrial facilities or warehouses. Industrial facilities and warehouses often have concrete floors or walls that are susceptible to water damage from leaks or moisture. By applying a waterproofing membrane, these areas can be protected against water penetration, preventing potential damage to the structure and its contents. Waterproofing membranes are designed to create a barrier that prevents water from seeping through the surface, providing an effective solution for industrial facilities and warehouses where moisture control is essential. Additionally, these membranes are durable and can withstand heavy foot traffic and equipment, making them suitable for use in high-traffic areas. Overall, using a waterproofing membrane in industrial facilities or warehouses can help maintain a dry and safe environment, safeguarding the structure and its contents.

- Q: How does a waterproofing membrane handle structural cracks?

- The purpose of a waterproofing membrane is to prevent water from entering cracks in a structure and causing damage. This membrane is typically applied to the surface of the structure and acts as a protective layer, sealing the cracks and stopping water from infiltrating. When a structural crack occurs, the waterproofing membrane is able to bridge the gap and create a seal that is resistant to water. This is accomplished by using flexible materials that can stretch and move with the structure, accommodating any shifts or movements that may happen over time. Moreover, the membrane can adhere to various surfaces, ensuring a tight and secure bond that stops water from seeping through the cracks. Furthermore, certain waterproofing membranes have the ability to self-repair. In the event of a crack, the membrane can fix itself, closing the gap and maintaining its ability to repel water. In conclusion, a waterproofing membrane is an effective solution for managing structural cracks. It provides a strong and flexible barrier that prevents water intrusion and safeguards the integrity of the structure. It is crucial to choose the appropriate type of membrane for the specific structural requirements and to ensure proper installation in order to achieve the desired waterproofing outcomes.

- Q: Can waterproofing membranes be used on concrete planters?

- Yes, waterproofing membranes can be used on concrete planters to prevent water leakage and protect the concrete from moisture damage.

- Q: Are waterproofing membranes resistant to high temperatures?

- Yes, waterproofing membranes are typically designed to be resistant to high temperatures. They are made from materials such as modified bitumen, PVC, or EPDM that have excellent heat resistance properties, allowing them to withstand high temperatures without degrading or losing their waterproofing capabilities.

- Q: SBS waterproofing membrane sub-class I and II when to use what level to use a secondary level

- Classification: According to physical indicators are divided into: Ⅰ (-20 ℃), Ⅱ (-25 ℃) type two categories; According to the fetal base can be divided into: polyester tires, glass fiber tire two categories; according to the surface material can be divided Waterproof sheet

Send your message to us

SBS Elastomer Modified-bitumen Waterproof Membrane For Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords