Economic Metallized Film Packaging Material for Food and Medicine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Economic Metallized Film Packaging Material for Food and Medicine

Dear customers,

We are the only nationalized business manufacturer of packaging film, was founded in 1995.

Our company is specializing in metallized cpp pet (vmcpp & vmpet) for more than 22 years. We are proud of first quality with outstanding service and competitive price. Hope to cooperate with you in the future.

Does not contain hazardous chemicals o harmful materials that cause itching or respiratory problems.

Does not contain hazardous chemicals o harmful materials that cause itching or respiratory problems.

Reflects 97% radiant heat, improves insulation system performance, energy saving.

High tensile strength VMPET.

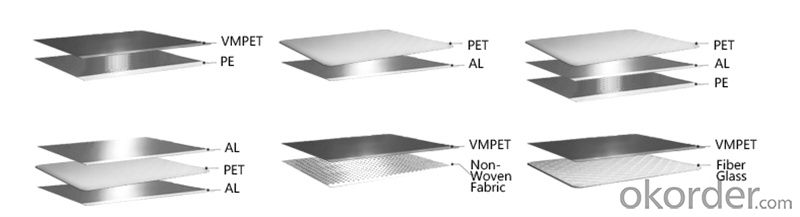

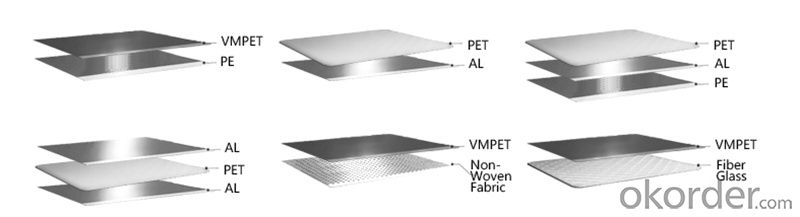

Economic metallized film mylar reflective material from factory

Easily install it on long-span building such as warehouse, factory building, supper market, gym, container liner VMPET.

| Setting Information | |

| Name | Metalized VMPET film |

| Material | VMPET film for lamination-LN2 |

| Property | Indicators |

| Application | Package |

| Processing Type | Casting |

| Usage | Packaging Film |

| Inner core | 95MM |

| Thickness | 12mic-180mic |

Product Description

VMPET film for lamination

Good ventilation, antistatic and transparency

Non-toxic and eco-friendly, biodegradable and recycled

Good print ability, distinguished gloss, excellent abrasion resistance

Custom size and design ,different sizes for various choices

Widely used for food and gifts packing, bags and so on

High tensile strength, low static

Excellent stiffness and fold ability

Good heat sealing ability in high speed

| Model | vmpet12 | vmpet60 | vmpet180 |

| Thickness | 12mic | 160mic | 180mic |

| Optical density | 1.6-2.4 | 1.6-2.4 | 1.6-2.4 |

| Inner core | 3" or 6" | 3" or 6" | 3" or 6" |

Our Advantage

Superiority of price: we control the whole process from raw materails purchasing to final product manufacturing.

Efficiency advantage: the fastest time of delivery is 7days.

Customization: all indicators could be customized which includes the thickness, width, length, diameter.

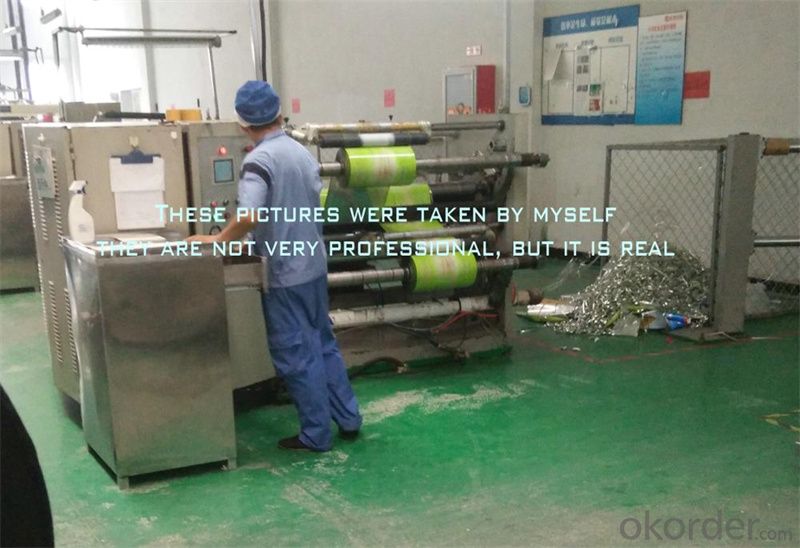

Device Show

- Q: What is the effect of plastic film on waterproof coiled material?

- As an insulating layer of asphalt base (to prevent production and adhesion during roll formation)

- Q: A concrete cover film, under what circumstances to cover, what does not cover

- The thin film is a thin, soft transparent sheet. Made of plastics, adhesives, rubber, or other materials. A scientific interpretation of a polyester film is a 2 dimensional material formed by atoms, molecules, or ions deposited on the surface of a substrate. Example: optical film, composite film, superconducting film, polyester film, nylon film, plastic film and so on. Films are widely used in electronic, electrical, mechanical, printing and other industries.

- Q: What is the plastic film under the wooden floor?

- It's called the ground mat, and it can play the role of separating the tide. If there is no floor mat, the floor will rub against the cement floor and make a noise. It's the biggest headache. Also, it can also play a role in leveling the ground. Is an indispensable program.

- Q: What's the difference between PE plastic film and PVC plastic film?

- PE: flammable, away from flame continues to burn, flame yellow blue, melt dripping, paraffin taste PVC: not flammable, away from the fire that destroyed the flames, yellow green with white smoke, softening without melting, pungent sour PE film is mainly used for industrial products: equipped with membrane, with high tensile strength. High elongation rate, good self-adhesive, high transparency point.

- Q: New car tires have a transparent plastic film, will not be a problem car, new tires, or the car is the same when you leave the factory?

- If 4 are available, it's not a problem, but I've never seen a plastic film on a new tyre

- Q: Would you please put a plastic film on the bottom of the tent and put a plastic film on the top of the tent for lightning protection?

- Rain proof, moisture proof, lightning protection, and no eggsWell, I think that if you are not dead or unlucky, lightning not be split into your head. Then you need to be more careful about what happens to you when the lightning hits another place.

- Q: What kind of material is plastic film?

- Plastic film generally has polyethylene, polypropylene, PVC and other plastic materials.

- Q: PVC and PE plastic film, which can be used as food preservative film?

- With PE material, PVC can not be used as food packing even if it is environmental protection material

- Q: Wrap your legs in plastic film. How soon will they be removed?

- PVC film is mainly used in1. Sewage pipes2, PVC plastic film rod plate.3, construction, packaging, printing, equipment, process products.

- Q: What solvent can be used to remove the plastic film glued to the glass?

- You can remove nitro thinner scrub.Nitro thinner is used in automobile paint lacquer, the car paint, and then use the nitro thinner cleaning spray gun. The diluent is allergic to the skin, after evaporation, skin itching feeling, also feel hot.

Send your message to us

Economic Metallized Film Packaging Material for Food and Medicine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords