Composite Durable and Corrosion-Resistant Gre Pipes

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m

- Supply Capability:

- 5000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Advantages:

1. Durable in use and corrosion-resistant:the surface of internal and external can resist many kinds corrosion of chemicals, crude oil. injected water and bacteria.

2. Light weight: 24% weight of ductile iron, it is convenient for installation in the absence of heavy machinery and large tools.

3. Low cost: Internal surface can reduce friction and the cost of transporting by pump.

4. Efficient and eneray saving: GRE pipe compared with steel tube can reduce the consumption of heat.

5. The solution of pipe system: The whole FRP pipe have different size, pipe joints, pressure rating for choice.

6. The long life cycle and low cost: There is almost no maintenance costs after installation and use, and it has higher lifetime cost compared with steel tube.

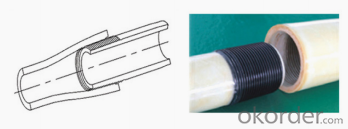

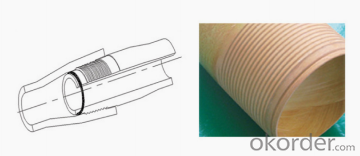

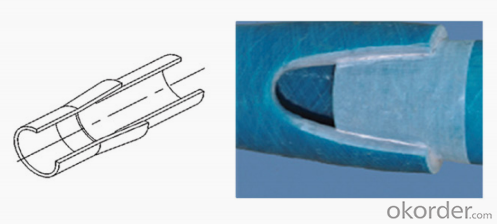

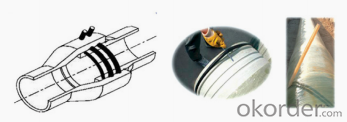

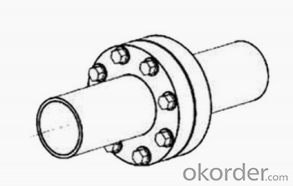

Joint type:

1. API thread application: High pressure oil & gas & water pipeline

2.T thread joint application: High pressure oil & gas & water pipeline

3.Bonding joint application: Underground low pressure pipeline

4.Locking key joint application: Underground low pressure pipeline

5.Flange joint application: Pipe and pipe or pipe joint other equipment

6.Lamination joint application: Low pressure pipeline connection

Produts Application:

1.Oil & gas-onshore:

Crude oil gathering line

Injected water

Macromolecule

Process pipeline in station

LNG pipeline

1. Vessel and offshore platform

Ballast water

Cooling water

DrainageFresh water pipe

Drinking water

Fire fighting water pipe

Sea water transport

Sewage transport

2. Bittern special purpose

Transport bittern

Transport sewage

3. Underground pipe and casing pipe

CBM casing pipe

Shale gas casing pipe

Underground oil pipe

Oil casing pipe

Product Performance:

The corrosion picture comparison between ordinary steel pipe and FRP pipe:

Performance comparison between ordinary steel pipe and FRP pipe:

Comparison Item | GRE pipe | Ordinary Steel Pipe |

Corrosion Resistance | Good corrosion resistance | Bad corrosion resistance |

Service Life | 20-30 years(the designed service life is more than 50 years ) | 5-10 years (nocathodic protection and preservative) |

Frictional Resistance | Smooth inner wall can reduce the accumulation of paraffin and scale;Low surface friction increase the flow of fluid velocity | The rough inner surface is easy to form scale and paraffin deposition;High surface friction leads to loss of workpressure |

Insulation Performance | There is no minimum and additional insulation material" requirement under high temperature and harsh environment | A lot of heat loss under the condition of high temperature |

Engineering Installation | Light weight, low cost of installation and transport | High weight, high cost of installation and transport |

Maintenance Fecs | It almost need no repair | Need anti-corrosive paint, cathodic protection and corrosion monitoring |

Environmental Performance | Low energy consumption in the process of productionand use | High energy consumption in the process of production and use |

Production Information:

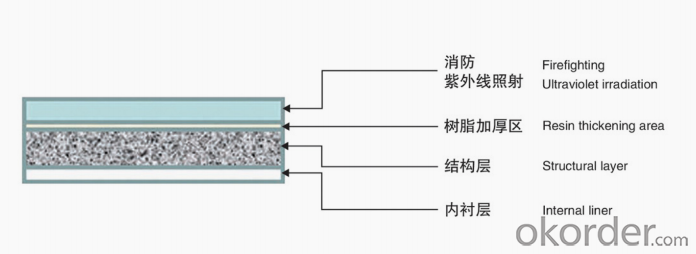

GRE wall structure:

∙ Pipe internal liner is used for anti-corrosion

∙ Pipe structural layer is used for pipe strength

∙ Anti-uv protection can used in pipe external to resist uv & the weathering exposure and environmental protection

∙ If high flow conducting electrostatic discharge need, GRE pipe can be used to conduct harmful static electricity discharged in the danger zone

In the fire, protective layer meet the fire resistance performance of protection box, required by firefighting, and produce less harmful gas.

Jet fire and fire-resistant experiment:

Level 3 fire-resistant experiment:

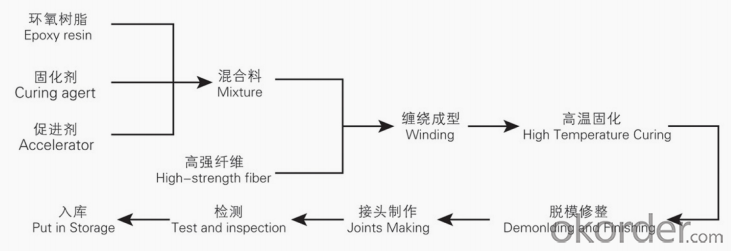

Production Method:

∙ Filament winding is used for both pipe and fitting production.

∙ The fiber glass will be winded on the mandrel after soaked into the resin. The mandrel will be rotated according to programmed mode.

∙ Multiply mandrels can be winded at the same time with one winding machine which has improved the work efficiency and guaranteed the quality.

∙ The winding of pipe fittings I flange, elbow, tee, coupling ) are made of two axis winding machines.

Production Process:

Quality Control:

Universal tester Differential scanning calorimeter (DSC)

Drying oven Fatigue tested machine

Before delivery, all pipes conduct 100% hydrostatic pressure monitoring in accordance with API standard.

Standard & Specification:

∙ API 15HR Specification for High Pressure Fiberglass Line Pipe

∙ API 15LR Specufcation for Low Pressure Fiberglass Line Pipe and fittings

∙ ISO 14692 Petroleum and natural gas industries - Glass-reinforced plastics (GRP) piping

∙ AWWA C950 Standard for fiberglass pressure pipe

∙ AWWA M45 Fiberglass pipe design

∙ IMO Res.A753(18) Plastic pipes on the ship

∙ ASTM F1173 Standard Specification for Thermosetting Resin Fiberglass Pipe Systems to Be Used for Marine Applications

∙ ASTM---D2996 Standard Specification for Filament-Wound "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

∙ API 5B Casing, tubing. line pipe thread specification

- Q: What can be done to solve the leakage of FRP pipe?

- The method of mending is hand paste. The stones must be taken away so that the pipes are restored to their original shape. If you can get into the pipe, polish it first and repair the lining.

- Q: What's the difference between glass fiber reinforced plastic pipe and glass fiber reinforced sand pipe? What kind of material is good?

- Sand tube is more brittle, gfrpmp is relative to the glass tube can be called pure glass tube, glass tube is not with quartz sand, the two pipes generally used in different areas, the pure glass pipe can be used in most areas, but the sand tube is generally only used in the political field, especially is the large diameter sand tube.

- Q: Is there any ventilation duct made of glass fibre reinforced plastic in Baotou?

- 1. Corrosion resistant FRP pipes resist acid, alkali, salt, sea water, untreated sewage, corrosive soil or groundwater, and the corrosion of numerous chemical fluids.2, good frost resistance FRP heat pipe temperature range between 40 to 80 DEG C, if the first with a special resin use temperature can reach higher.

- Q: How much is a glass fiber reinforced plastic sand pipe socket pipe fitting?

- Compared with the traditional pipe, it has excellent chemical resistance. It can resist acid, alkali, salt, oxidant, organic solvent, various kinds of grease, sewage and so on. Its lining is made of corrosion resistant and excellent resin as raw material, so no corrosion protection is needed. And after long-term use, no fouling, will not be contaminated by micro-organisms and debris deposition in the sewage, so as to increase the roughness rate and reduce the water cross section or plug the pipeline. Because the damage rate of glass fiber reinforced sand pipe is more than 4 times the working pressure, the safety factor is designed with enough safety factor.

- Q: There is a gap between the new glass fiber reinforced plastic pipe and its through wall. How can the plug be prevented from leaking through the cracks around the pipe?

- Through wall holes, made of other materials, wall fittings, ship wall fittings and glass fibre reinforced plastic pipes, flanges or other forms of connections are used, which may be referred to the application of the components of the ship piping;

- Q: What's the difference between glass fiber reinforced plastic pipe and glass fiber reinforced sand pipe?

- Sand sandwiched glass fiber reinforced plastic pipes only have more than one sand sandwiched with glass fiber reinforced plastic pipes, and sand layer can be understood to replace glass fiber with quartz sand. The sand pipe with the same thickness is compared with the glass fiber reinforced plastic pipe, but the sand holding pipe is cheap, but the strength is poor; and the glass steel pipe is opposite.

- Q: How is the glass reinforced septic tank and the cement drain pipe connected?

- The interface can be bonded with epoxy resin adhesive. The epoxy resin strongly adhere to the two materials, but the bonding surface must be clean.

- Q: What is the structure and function of glass fiber reinforced plastic lining?

- Repeat the process of brushing and sticking, forming three cloth, four glue or four cloth, five glue process, according to the corrosive strength of the medium, the thickness of the glass fiber reinforced plastic lining layer is different, and the price is different.FRP lining is slightly cheaper than rubber lining, but the price is only about 30% of the latter

- Q: Who knows, how is the glass reinforced septic tank connected with the municipal pipe?

- Septic tank (Hu, F, NCH) is the treatment of nightsoil and to filter precipitation equipment. The principle is that the cured material decomposes at the bottom of the tank, and the upper hydration object flows into the pipeline to prevent the pipe from clogging and has enough time to hydrolyze the solidified object (such as excrement and urine). Tank (septic) refers to the division of living sewage sludge, and anaerobic digestion of sludge structure of small structures.

- Q: What kind of epoxy resin and formula do you need for making fiberglass pipe?

- By explaining the materials, tools, moulds, renovation and repair, process, structure and various products, the latest development direction, process technology and application of FRP products are described.

Send your message to us

Composite Durable and Corrosion-Resistant Gre Pipes

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m

- Supply Capability:

- 5000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Lianyungang Zhongfu Lianzhong Composites Group Co.,Ltd.

Lianyungang Zhongfu Lianzhong Composites Group Co.,Ltd.