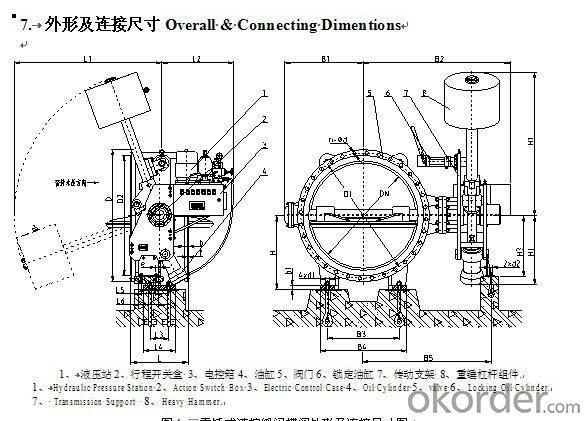

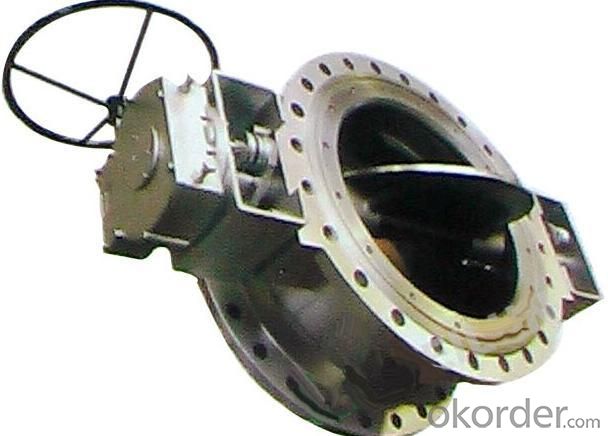

Double or Triple Eccentric Butterfly Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Double or Triple Eccentric Butterfly Valve

Offset high performance butterfly valves are designed in accordance with API 609 with advantages of bi-directional lightweight, cost-effective and low operation torque. Wide working temperature range covers -196℃~ 650℃, ideal for most various industry flow control system.

Design Feature of Double or Triple Eccentric Butterfly Valve

1. Triple offset or Double offset

2. Zero leakage

3. Frictionless closure

4. Blowout-proof stem

5. ISO 5211 top flange

6. Optional extended stem design

7. Optional stellited seat

8. Optional various actuator

Product Range of Double or Triple Eccentric Butterfly Valve

Size: 3~56”(DN80~DN1200)

Rating: 150~600LB(PN16~PN100)

Body Materials: Carbon Steel, Stainless Steel, Alloy Steel, Duplex Steel

Seat Materials:Graphite laminated

End connection: Wafer, Lug, Double Flange

Operation: Electric, Pneumatic

- Q: Butterfly valve D41W-1, 41, W, 1, respectively, what does that mean?

- D--- stands for butterfly valves; 4--- refers to the form of flange connections; 1--- refers to the valve stem and disc in the center of the valve line, without eccentricity; w--- refers to the valve seat material and body material is the same, usually carbon steel. The final 1--- refers to the nominal pressure of 1 kg / cm2.

- Q: Have an iron block, aluminum heads, solid roller lifters, Jessel rocker shafts, what should my valve clearances be cold, and hot??

- Well, generally it's going to be .030 intake and exhaust (hot). Adjust to those clearances cold then recheck at operating temp. But it would really help to know year, make, cu. in., which aftermarket heads, to be absolutely sure. On some engines it is .024 intake / .030 exhaust and so on, depends on the lifters and valve train geometry.. What brand of lifters and cam profile? Usually they will specify valve lash and adjusting procedures. Edit: Wow, kinda' tight valve lash, krazybob, ( might be a lttle tough on the old cam lobes), and then there is your timing numbers / advice with absolutely no details to base it on ( H.E.I.?..which brand? / mechanical advance curve?, and vacuum advance numbers?, cam timing, brand of lifters, cam specs, rocker arm ratio)...Look, S-51D, the best idea is to Do- It- Right using the correct adjustment specs. The data is out there, once the configuration is identified.

- Q: The water supply pipe is the gate valve And on the cross dry pipe are the gate valve? To answer the 30

- I suggest you find out the pressure and installation position first, the condition allows, you can choose butterfly, after all, much cheaper than butterfly valve. After the completion of the project, will be mainly engaged in the acceptance of problems, there are special management of fire units.

- Q: What does the butterfly valve model d344h, d345h, d346h, d347h mean?

- According to the international standard of the letters and numbers apart to explain D344H D is a unit of butterfly valve, two unit 3 is driving mode: turbine, three unit 4 connection: flange connection, four unit 4 Structure: seal type linkage, five unit H sealing material: Cr13 stainless steelD345H compare yourself to the above. Unit 5 four is a sealed, single eccentric structureD346H four unit 6 is an unsealed center vertical plateD347H four unit 7 is unsealed double eccentricIn general, there is only one difference between them: the structural form is different!

- Q: Butterfly valve D71X-10 and butterfly D371X-10 what is the difference?

- One is the turbine drive and the other is with the handle

- Q: I have put a new pressure valve and replaced both thermostat

- If you have replaced the TP valve, more than likely there is a heating element shorted to the tank. This will cause continuous heating and high temp/high pressure...good luck.

- Q: 19 years ago i had a valve repair and now im due to have heart valve replacement. I heard that the metal valve make noise has anyone who has had the metal valve have this type f problem or any other problem with the metal valve it would be a great help if anyone could answer

- Do you want to have kids or have more kids? This is going to be the biggest question you have to answer. The tissue valve will require no treatment after the replacement, other than another replacement in 10-15 years or whenever the valve starts to fail. The mechanical valve will most likely last the rest of your life, but will require the use of anticoagulants that would make any future pregnancy extremely risky. As to the sound many patients complain about hearing the valve clicking in times when it is very silent (dead of night etc.) Most find that keeping a Radio or tv on at a low level solves the problem, Id say in my experience about 50% of patients complain about hearing the clicking. The other issue is that using tissue valves, it is a slightly riskier operation every time you re-open someones chest, due to scar tissue formation. So instead of say 1-3% risk it might be 5% if the person is young and healthy. This is important since the tissue valve will only last 10 maybe 15 years. The atrial thrombus complicates matters, however which valve are they replacing? It might be possible to remove the thrombus at the same time as doing the valve. If not, mo matter what you will be taking warfarin, so the vavle choice really will not matter that much.

- Q: The difference between the directly buried gate and the flange valve and butterfly valve

- Buried gate also called buried gate valve, valve can be directly buried underground, built without manhole, reduce road excavation area; small well maintained road and beautiful room can reduce the difficulty of construction, reduce project cost. The directly buried soft sealing gate valve is divided into two types: telescopic type and fine fixing type, wherein, the telescopic type is divided into metal type and plastic type. In the process of construction, the telescopic type can be adjusted arbitrarily according to the distance between the buried depth of the valve and the ground, and the micro adjustment can be adjusted on the spot. The directly buried gate valve has the advantages of long-term use, no leakage, no maintenance, etc., and can effectively avoid other people switching the valve and stealing the manhole cover at will.Flange gate valve is connected to the flange gate valve, this connection is the most common way.

- Q: e.g. a patient with a prosthetic aortic valve and a patient with a prosthetic mitral valve. Also, can you get stenosis of mechanical valves or just tissue grafts?Thanks!

- mechanical okorder /

- Q: 1988 volkswagon cabriolet, rabbit tried mystery oil let sit for a week having trouble with stuck valves even taken a wrenrch to manually unstick. help any suggestions 4 cyclinder car has been sitting up for about 4 years

- The only reason for a stuck valve is if it bent from a thrown timing belt. Sitting 4 years will not cause valves to stick usually, because there is always some oil leakage from the head, that prevents rust. How do you know the valve is stuck? Have you done a compression test, checked the valve clearance? When you say you take a wrench to manually unstick it, it would help to know what you mean, because there is no place to put a wrench that would help unstick a valve that was stuck. You need to tell us much more.

Send your message to us

Double or Triple Eccentric Butterfly Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches