DOUBLE-COATED PREPAINTED GALVANIZED STEEL COILS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000TONS m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

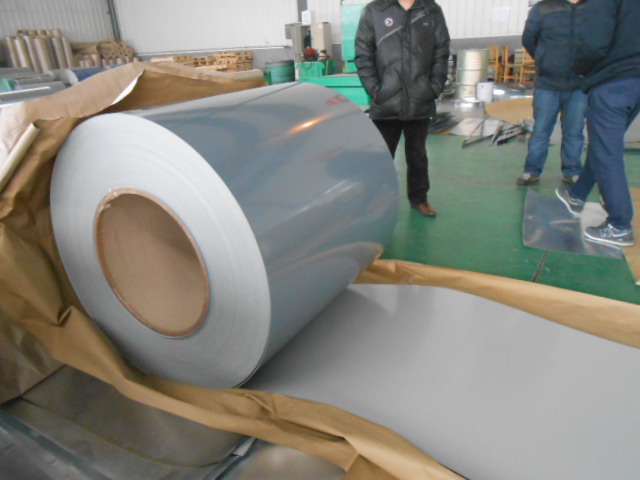

DOUBLE-COATED PREPAINTED GALVANIZED STEEL COILS

THICKNESS:0.95mm(-/+0.02mm)

WIDTH:1250mm(0/+5mm)

ZINC COATING:60g/m2 (-/+10g/m2)

COLOR: ACCORDING TO COLOR SAMPLE.

TOP COATING:5+13 MICRON, BACK COATING:5+13 MICRON; (-/+2MICON)

COIL WEIGHT:3-5 ton

STANDARD:JIS G 3312

STEEL GRADE:CGCC

COIL ID:508mm

- Q: What are the different coil packaging materials used for steel coils?

- The different coil packaging materials used for steel coils include steel strapping, plastic strapping, stretch wrap, and wooden crates.

- Q: How are steel coils used in the production of steel bolts?

- Steel coils are used in the production of steel bolts by being uncoiled and then fed into a machine that cuts and forms the bolts. The coils provide a continuous supply of high-quality steel, ensuring consistent and precise production of bolts.

- Q: What are the dimensions of steel coils used in the storage system industry?

- The dimensions of steel coils used in the storage system industry vary depending on the specific requirements of the storage system and the industry it is used in. However, common dimensions for steel coils used in storage systems can range from 0.15mm to 3.5mm in thickness, and from 600mm to 2100mm in width. The length of the coils can also vary, typically ranging from 1000mm to 6000mm.

- Q: What are the different grades of steel used for making coils?

- There are several different grades of steel that are commonly used for making coils, depending on the specific application and requirements. Some of the most commonly used grades include: 1. Low carbon steel (also known as mild steel): This grade of steel is often used for making coils as it offers good formability, weldability, and machinability. It is suitable for a wide range of applications where strength and durability are not the primary requirements. 2. High carbon steel: This grade of steel contains higher levels of carbon, which provides increased strength and hardness. It is commonly used for making coils that require high strength and resistance to wear and tear, such as springs and automotive components. 3. Stainless steel: This grade of steel contains a high percentage of chromium, which provides excellent corrosion resistance. Stainless steel coils are commonly used in applications where resistance to rust and staining is crucial, such as kitchen appliances, automotive trim, and medical equipment. 4. Galvanized steel: This grade of steel is coated with a layer of zinc, which provides excellent corrosion resistance. Galvanized steel coils are commonly used in outdoor applications where exposure to moisture and other elements is a concern, such as roofing, fencing, and HVAC ductwork. 5. Electrical steel: This grade of steel is specially designed for use in electrical applications, such as transformers, motors, and generators. It has low levels of impurities and is optimized for high magnetic permeability and low core loss. 6. Advanced high-strength steel (AHSS): This grade of steel is engineered to provide exceptional strength while maintaining good formability. AHSS coils are commonly used in the automotive industry for lightweighting vehicles while ensuring structural integrity and crashworthiness. These are just a few examples of the different grades of steel used for making coils. The specific grade chosen will depend on factors such as the intended application, desired properties, and cost considerations.

- Q: Why people prefer prefabricated buildings these days? Recently my friend has told me that he is going to owe a steel house so I was just thinking are these steel structures really durable and cheaper than concrete structures?

- It really depends upon the environment and the construction techniques used. Steel that is painted or coated will without maintenance eventually rust. I would expect this tendency to be exacerbated in a humid or shore environment. Heat may tend to cook a steel house and the structure does not add much thermal mass. Construction techniques tend to be fairly quick a part of the construction is essentially prefabricated. Work done in a factory will almost always be cheaper than work done in the field, all things being equal. Concrete can be fairly hi tech with lots of equipment or as seen in many parts of the world fairly low tech with lots of laborers. It is easy to change the characteristics of concrete depending upon how it is mixed, reinforced, and treated during the curing process. Because it is applied in a relatively fluid state it can flow around obstructions like bedrock and be formed up into interesting shapes. A concrete structure can be cooler as it provides thermal mass, and a heat sink. It's resulting rigidity may make it more subject to earthquakes than steel. We do really need to be smarter in constructing our homes to make them fit the land and not only the general environment but our particular micro environment.

- Q: What are the common applications of steel coils?

- Steel coils have a wide range of applications, commonly used in industries such as automotive, construction, manufacturing, and appliances. They are utilized for making various products including automobiles, pipes, electrical appliances, roofing, and packaging materials.

- Q: How are steel coils used in the production of storage systems?

- Steel coils are used in the production of storage systems by being formed into sheets or strips, which are then shaped and welded to create the framework and shelves of the storage units. The high strength and durability of steel make it an ideal material for supporting heavy loads and ensuring the longevity of storage systems.

- Q: How do steel coils contribute to the manufacturing of HVAC systems?

- Steel coils are used in the manufacturing of HVAC systems primarily for their strength and durability. They form the core structure of various components such as heat exchangers, condenser coils, and evaporator coils. The steel coils provide stability and support, ensuring the longevity and efficiency of HVAC systems by withstanding high temperatures, pressure, and constant use.

- Q: Can steel coils be coated with thermally insulating materials?

- Yes, steel coils can be coated with thermally insulating materials. These materials help to reduce heat transfer and provide insulation to the steel coils, enhancing their thermal resistance.

- Q: iam talking abt carbon steel of composition:-C=0.15wt% Mn=0.60wt% P=0.035wt% S=0.04wt% Cu=0.20 (min)wt%....

- The composition of the steel is almost tertiary to many other considerations, except that there are certain elements and percentages of elements which tend to affect the crystaline structure in the steel. The most basic question is whether the crystaline arrangement of atoms in the steel is martensitic or austenitic, and many factors influence that. In general, martensitic structure is magnetic and austenitic structure doesn't respond much to magnetic fields, but there are varying degrees of martensitic and austenitic -- there is never a pure state. Read the articles at bottom.

Send your message to us

DOUBLE-COATED PREPAINTED GALVANIZED STEEL COILS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000TONS m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords