Poly Aluminum Coil C83868 - Direct Rolled Aluminum Coil for Architecture China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Direct Rolled Aluminum Coil for Architechture China Supply

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Direct Rolled Aluminum Coil for Architechture China Supply

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Direct Rolled Aluminum Coil for Architechture China Supply

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

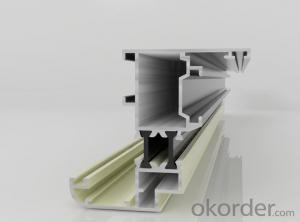

5. Image of Direct Rolled Aluminum Coil for Architechture China Supply

6. Package and shipping of Direct Rolled Aluminum Coil for Architechture China Supply

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the width tolerances for aluminum coils?

- The width tolerances for aluminum coils can vary depending on the specific application and industry standards. However, in general, the standard width tolerances for aluminum coils typically range between +/- 0.005 inches to +/- 0.020 inches. These tolerances ensure that the width of the aluminum coil falls within an acceptable range and meets the required dimensions for the intended use. It is worth noting that tighter tolerances may be achievable depending on the specific manufacturing processes and equipment capabilities. Therefore, it is essential to consult the appropriate industry standards and specifications to determine the exact width tolerances required for a particular application.

- Q: How should aluminum coil be stored to maintain its quality and prevent damage?

- <p>The best way to store aluminum coil involves several key practices: Store the coil in a clean, dry, and well-ventilated area to prevent moisture and dirt accumulation. Ensure the storage area is free from corrosive substances and temperature fluctuations. Use pallets or racks to keep coils off the ground, and avoid stacking heavy items on top. Protect coils with plastic covers or wrapping to prevent dust and scratches. Organize coils by size, type, and grade for easy access and to prevent damage during handling. Regularly inspect stored coils for signs of damage or corrosion and rotate stock to minimize prolonged storage of any single coil.</p>

- Q: What are the advantages of using aluminum coils over other materials?

- There are several advantages of using aluminum coils over other materials. Firstly, aluminum is a lightweight material, making it easier to handle and transport. This lightweight nature also makes it more cost-effective as it requires less energy to manufacture and install. Secondly, aluminum has a high level of corrosion resistance. It does not rust, even when exposed to harsh environmental conditions, making it suitable for outdoor applications. This durability ensures a longer lifespan and reduces maintenance costs in the long run. Additionally, aluminum coils provide excellent heat transfer properties. They have a high thermal conductivity, allowing for efficient heat exchange. This makes them ideal for applications such as heating, ventilation, and air conditioning systems, where effective heat transfer is crucial. Moreover, aluminum is a highly recyclable material. It can be recycled repeatedly without losing its quality or performance. This not only reduces waste and contributes to environmental sustainability but also lowers production costs. Lastly, aluminum coils offer versatility in terms of design and customization. They can be easily formed, shaped, and coated to meet specific requirements. This flexibility allows for a wide range of applications in various industries, from automotive and construction to electronics and aerospace. Overall, the advantages of using aluminum coils, including its lightweight nature, corrosion resistance, heat transfer properties, recyclability, and versatility, make it a preferred choice over other materials.

- Q: Can aluminum coils be used for HVAC condenser coils?

- Indeed, HVAC condenser coils can utilize aluminum coils. In recent times, aluminum coils have gained significant popularity owing to their myriad benefits over conventional copper coils. With their lighter weight and enhanced durability, aluminum coils exhibit superior resistance to corrosion. Additionally, they boast exceptional heat transfer properties that enable efficient refrigerant cooling. Furthermore, aluminum coils prove to be more cost-effective and environmentally sustainable in comparison to copper coils. All in all, opting for aluminum coils for HVAC condenser coils is a viable and advantageous choice.

- Q: What is the typical elongation of aluminum coils?

- The elongation of aluminum coils can vary depending on various factors, including the specific alloy and temper of the aluminum, the manufacturing process, and the intended application. However, aluminum coils generally have a high capacity for elongation. On an average basis, aluminum coils can stretch or deform by approximately 5-15% without fracturing or breaking. This is possible due to the inherent ductility of aluminum, which enables it to be easily shaped and formed without compromising its structural integrity. The elongation of aluminum coils plays a significant role in multiple industries, such as construction, automotive, and aerospace, where the material is commonly utilized. This characteristic allows for efficient fabrication procedures, including bending, rolling, and stamping, to create intricate and precise shapes. It is important to highlight that the elongation of aluminum coils can be further enhanced through the incorporation of specific alloying elements and heat treatments. These processes can improve the material's properties, making it even more suitable for demanding applications that require exceptional strength, ductility, and elongation capabilities. To accurately determine the elongation properties for a specific application, it is crucial to consider the particular alloy, temper, and manufacturing processes involved. In conclusion, while the typical elongation of aluminum coils ranges from 5-15%, a comprehensive evaluation of these factors is necessary.

- Q: Can aluminum coils be used for cladding purposes?

- Yes, aluminum coils can be used for cladding purposes. Aluminum is a popular choice for cladding due to its durability, lightweight nature, and resistance to corrosion. The coils can be formed into various shapes and sizes, making them suitable for cladding applications in industries such as construction, architecture, and manufacturing.

- Q: Can aluminum coils be used in the production of aluminum doors?

- Aluminum doors can be produced using aluminum coils. Typically, aluminum coils serve as a raw material in the manufacturing process of aluminum doors. These coils are constructed from top-notch aluminum alloy and are available in varying thicknesses and widths. They can easily be molded into different shapes and sizes to fulfill the particular requirements of the doors. Furthermore, aluminum coils possess characteristics such as lightweightness, durability, and resistance to corrosion, making them an excellent option for door production. The coils are commonly subjected to various techniques like cutting, bending, and welding to fabricate the desired door components. All in all, aluminum coils offer numerous advantages in terms of versatility, strength, and aesthetics, which explains their popularity among aluminum door manufacturers.

- Q: What house hold materials contain 100% pure aluminum. or where can i buy it. im making thermite, which ive made before so don't say, its dangerous don't do it, but do i need 100% pure aluminum or will some aluminum alloy with like 90% aluminum work?????

- Aluminum foil is your best bet. According the the Reynold's wrap web site, their foil is 98.5% aluminum.

- Q: How are aluminum coils used in gutter systems?

- Aluminum coils are commonly used in gutter systems for their durability and resistance to corrosion. Gutter systems are designed to collect rainwater and direct it away from the roof and foundation of a building to prevent water damage. Aluminum coils are used to create seamless gutters that are custom-fitted to the dimensions of a particular structure. The process begins with an aluminum coil that is fed through a specialized machine called a gutter machine. This machine forms the coil into the shape of a gutter, typically in a continuous length that can extend the entire length of the roofline without any seams. The coil is shaped to create a trough-like structure with a slight slope to allow water to flow easily towards downspouts. Aluminum is an ideal material for gutter systems as it is lightweight yet strong, making installation easier and reducing the risk of sagging or bending. It is also resistant to rust and corrosion, ensuring the longevity of the gutter system even in harsh weather conditions. Additionally, aluminum can be easily painted or coated to match the aesthetic of the building. Once the seamless gutters are formed from the aluminum coil, they are typically secured to the edge of the roofline using hangers or brackets. Downspouts are then attached to the gutters at strategic points to direct the collected rainwater away from the building's foundation. These downspouts can also be made from aluminum coils, ensuring a seamless and cohesive appearance throughout the entire gutter system. In summary, aluminum coils are used in gutter systems to create seamless gutters that provide effective and efficient water drainage. Their durability, resistance to corrosion, and ease of installation make them a popular choice for gutter systems in residential, commercial, and industrial buildings.

- Q: Are aluminum coils suitable for interior design applications?

- Yes, aluminum coils are suitable for interior design applications. Aluminum is a versatile material that offers durability, lightweight properties, and resistance to corrosion. It can be easily shaped, painted, or coated to match various design aesthetics. Additionally, aluminum coils are commonly used for decorative purposes like ceiling panels, wall cladding, and furniture components, making them a popular choice in interior design projects.

Send your message to us

Poly Aluminum Coil C83868 - Direct Rolled Aluminum Coil for Architecture China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords