Aluminum Coil Roll AA1050 H12 Direct Rolled Aluminum Coil China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of AA1050 H12 Direct Rolled Aluminum Coil China Supply

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of AA1050 H12 Direct Rolled Aluminum Coil China Supply

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of AA1050 H12 Direct Rolled Aluminum Coil China Supply

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

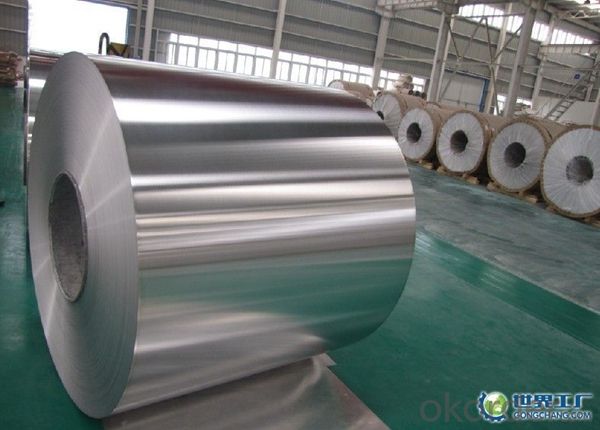

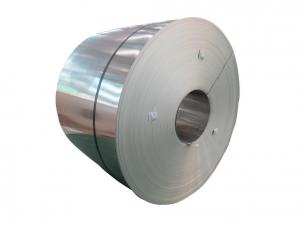

5. Image of AA1050 H12 Direct Rolled Aluminum Coil China Supply

6. Package and shipping of AA1050 H12 Direct Rolled Aluminum Coil China Supply

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the different grades of aluminum used in coil production?

- There are several different grades of aluminum that are commonly used in coil production. Each grade has its own unique properties and characteristics that make it suitable for specific applications. Some of the most commonly used grades include: 1. 1100 Aluminum: This grade is considered commercially pure aluminum and is known for its excellent corrosion resistance and high thermal conductivity. It is often used in applications such as heat exchangers, fin stock, and evaporator coils. 2. 3003 Aluminum: This grade is alloyed with manganese, making it stronger and more durable than 1100 aluminum. It also has good formability and weldability properties, making it suitable for a wide range of coil production applications, including roofing, gutters, and general sheet metal work. 3. 5052 Aluminum: This grade is alloyed with magnesium and has excellent corrosion resistance and high strength. It is commonly used in marine applications, such as boat hulls and components, as well as in architectural and automotive applications. 4. 6061 Aluminum: This grade is one of the most versatile aluminum alloys and is known for its high strength and excellent machinability. It is often used in structural applications, such as aircraft parts, truck frames, and industrial equipment. 5. 7075 Aluminum: This grade is one of the highest strength aluminum alloys available and is commonly used in aerospace and defense applications. It has excellent fatigue resistance and is often used in the production of aircraft wing spars, fuselage frames, and missile components. These are just a few examples of the different grades of aluminum used in coil production. The specific grade chosen will depend on the desired properties and requirements of the application.

- Q: Can aluminum coils be used for window frames?

- Yes, aluminum coils can be used for window frames. Aluminum is a popular choice for window frames due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in both residential and commercial applications. Aluminum coils can be easily shaped and manipulated to fit various window sizes and styles. Furthermore, aluminum frames offer excellent thermal insulation properties, which can help improve energy efficiency in buildings. Overall, aluminum coils are a reliable and practical option for window frame construction.

- Q: What are the different mechanical properties of aluminum coils?

- Aluminum coils are highly sought after for a variety of uses due to their diverse mechanical properties. Some key properties of aluminum coils include: 1. Strong: Aluminum coils are impressively strong, making them suitable for structural purposes. Their strength can be further enhanced through alloying or heat treatment processes. 2. Flexible: Aluminum coils are highly malleable, allowing for easy shaping and forming. This property enables the creation of intricate designs and complex shapes without compromising the integrity of the material. 3. Lightweight: Aluminum is known for its low density, making it one of the lightest metals available. This characteristic makes aluminum coils ideal for industries like aerospace and automotive, where weight reduction is crucial. 4. Resistant to corrosion: Aluminum naturally resists corrosion, forming a protective oxide layer that prevents further oxidation. This quality makes aluminum coils suitable for outdoor and marine environments, as they can withstand harsh conditions and require minimal maintenance. 5. Good conductivity: Aluminum is an excellent conductor of both heat and electricity. This characteristic makes aluminum coils ideal for applications that require efficient heat transfer, such as in heat exchangers and electrical wiring. 6. Easy to machine: Aluminum coils can be easily machined due to their low melting point and the way they form chips. This characteristic allows for high-speed machining operations, resulting in reduced production time and costs. 7. Weldable: Aluminum coils can be easily welded using various techniques, such as TIG or MIG welding. This characteristic enables the fabrication of complex structures and the joining of aluminum components. 8. Resistant to fatigue: Aluminum exhibits excellent fatigue resistance, allowing it to withstand repeated stress cycles without failure. This quality makes aluminum coils suitable for applications subjected to cyclic loading, such as automotive components or structures exposed to wind or waves. Overall, the combination of unique mechanical properties possessed by aluminum coils, including strength, flexibility, lightweight, corrosion resistance, conductivity, machinability, weldability, and fatigue resistance, makes them a versatile material choice for a wide range of industries and applications.

- Q: What is the cost of aluminum coils?

- The cost of aluminum coils can vary depending on various factors such as the thickness, width, and length of the coil, as well as the market conditions and the supplier. Generally, the price of aluminum coils is determined by the current market price of aluminum, which is influenced by factors like supply and demand, production costs, and global economic conditions. It is advisable to contact suppliers or check online platforms to get accurate and up-to-date pricing information for aluminum coils.

- Q: Is it possible to recycle old aluminum coils as scrap metal?

- <p>Yes, old aluminum coils can be used as a source of scrap metal for recycling. Aluminum is a highly recyclable material, and recycling it helps conserve resources and energy. Old aluminum coils can be melted down and repurposed into new aluminum products. It's important to ensure that the coils are clean and free of contaminants before recycling to maintain the quality of the recycled aluminum. Always check with local recycling centers or scrapyards for specific guidelines on recycling aluminum coils.</p>

- Q: What are the different elongation values of aluminum coils?

- The elongation values of aluminum coils can vary depending on the specific alloy and temper of the aluminum. Generally, aluminum coils have excellent elongation properties, which means they can be stretched or deformed without breaking. For example, the commonly used alloy 3003-H14 has an elongation value of around 20-30%. This means that the aluminum coil can stretch up to 20-30% of its original length before it breaks. On the other hand, high-strength alloys like 7075-T6 have lower elongation values of around 9-13%. These alloys are designed for applications where strength is crucial, but they sacrifice some elongation properties. It's important to note that elongation values can also be influenced by the processing and treatment of the aluminum coils. For instance, annealing or heat treatment can improve the elongation properties of certain alloys. In summary, the elongation values of aluminum coils can range from 9% to 30%, depending on the alloy, temper, and processing methods used.

- Q: Can aluminum coils be painted or coated for aesthetic purposes?

- Yes, aluminum coils can be painted or coated for aesthetic purposes. Aluminum is a versatile material that can be easily painted or coated to enhance its appearance. Painting or coating aluminum coils can provide a wide range of color options and finishes, allowing for customization and aesthetic appeal in various applications. The paint or coating can also provide additional protection against corrosion and weathering, increasing the durability and longevity of the aluminum coils. However, it is important to select the appropriate type of paint or coating that is compatible with aluminum and suitable for the intended use to ensure optimal results.

- Q: Can aluminum coils be used for automotive heat shields?

- Yes, aluminum coils can be used for automotive heat shields. Aluminum is a commonly used material for heat shields due to its excellent thermal conductivity and high melting point. It is lightweight and has good corrosion resistance, making it ideal for automotive applications. Aluminum coils can be easily formed into the desired shape and provide effective heat insulation, protecting sensitive components from excessive heat generated by the engine or exhaust system. Additionally, aluminum is cost-effective and readily available, making it a popular choice for automotive heat shields.

- Q: What is the typical thermal expansion coefficient for aluminum coils?

- The aluminum coils usually have a thermal expansion coefficient of approximately 23.1 x 10^-6 per degree Celsius (or 23.1 x 10^-6/°C). This coefficient signifies the alteration in length of an aluminum coil with each degree Celsius rise in temperature. It is worth mentioning that this figure might slightly differ based on the particular alloy and composition of the aluminum coil.

- Q: How do aluminum coils compare to galvanized steel coils in terms of longevity?

- Aluminum coils generally have a longer lifespan compared to galvanized steel coils. This is because aluminum is naturally corrosion-resistant, providing better protection against rust and other environmental factors. Additionally, aluminum coils are less prone to damage caused by scratches or dents, further contributing to their longevity. However, the specific lifespan of both types of coils can vary depending on the quality of materials used and the maintenance practices followed.

Send your message to us

Aluminum Coil Roll AA1050 H12 Direct Rolled Aluminum Coil China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords