3/8 Aluminum Coil - Mill Finished Direct Casting Aluminum Circle AA1050

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of DC Aluminium in Coil Form for making Aluminium Circle Description

DC Aluminium in Coil Form for making Aluminium Circle is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Feature of DC Aluminium in Coil Form for making Aluminium Circle

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

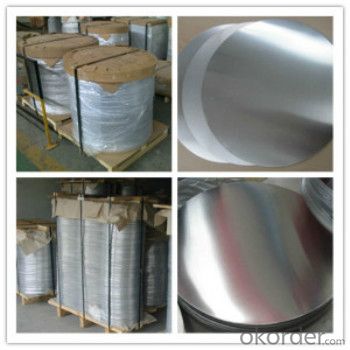

3. Image of DC Aluminium in Coil Form for making Aluminium Circle

4. Specification of DC Aluminium in Coil Form for making Aluminium Circle

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

5. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

4)What about payment term?

30% T/T in advance, balance against B/L COPY or 100% L/C AT SIGHT.

- Q: Can aluminum coils be used in automotive suspension systems?

- Yes, aluminum coils can be used in automotive suspension systems. Aluminum is a lightweight and durable material that offers several advantages for suspension components. It has a high strength-to-weight ratio, which means that it can handle heavy loads without adding unnecessary weight to the vehicle. This can result in improved fuel efficiency and overall performance. Additionally, aluminum is resistant to corrosion, which is especially important for automotive suspension systems that are exposed to harsh weather conditions and road debris. By using aluminum coils, manufacturers can ensure that the suspension components will last longer and require less maintenance. Furthermore, aluminum coils have the ability to absorb and dissipate heat more efficiently than other materials, such as steel. This can help prevent overheating and reduce the risk of suspension failure, particularly during intense driving conditions or off-road use. However, it is worth noting that the use of aluminum coils in automotive suspension systems may come with certain trade-offs. While aluminum is lighter and more resistant to corrosion, it may not be as strong as steel. Therefore, manufacturers must carefully design and engineer the suspension system to ensure it can withstand the necessary loads and provide adequate support and stability for the vehicle. In summary, aluminum coils can indeed be used in automotive suspension systems, offering benefits such as lightweight construction, corrosion resistance, and efficient heat dissipation. However, it is crucial for manufacturers to consider the specific requirements and trade-offs associated with using aluminum in suspension components to ensure optimal performance and safety.

- Q: Are aluminum coils suitable for medical equipment applications?

- Yes, aluminum coils are suitable for medical equipment applications. Aluminum is a lightweight and corrosion-resistant material, making it ideal for medical equipment that requires durability, cleanliness, and easy sterilization. Additionally, aluminum coils can be easily shaped and formed to meet specific design requirements, providing flexibility in manufacturing medical devices.

- Q: The temperature of the water drops from 93.0°C to 78.0°C. What quantity of heat energy did the piece of aluminum absorb?

- The specific heat of Aluminum is 0.215 cal/g-°C. The calories absorbed (q) would be q = m * c * (T2 -T1) = 22.0 g * 0.215 cal/g-°C * (78.0 °C - 0.3 °C) If you have a different value for the Specific heat of Aluminum, use it in the formula for your calculations. If you knew the mass of the water, you could check your calculations because the heat gained by the Al would be equal to the heat lost by the water, using q = m * c * (T2 -T1), where m is the mass of the water, c = 1.00 calorie/gram °C, T2 = 78.0 °C and T1 = 93.0 °C. The sign of q will be negative.

- Q: What are the compositions of aluminum coil coating?

- The common compositions are crylic resin, solid inorganic filler, different pigments, flatting agent and so on.

- Q: Are aluminum coils suitable for high-reflective applications?

- Yes, aluminum coils are suitable for high-reflective applications. Aluminum is known for its excellent reflectivity, with a reflectance ratio of around 80-90%. This makes it an ideal material for applications that require high reflectivity, such as in lighting fixtures, solar panels, and mirrors. Aluminum coils can be coated or polished to further enhance their reflective properties. Additionally, aluminum is lightweight, corrosion-resistant, and has good heat conductivity, making it a versatile choice for various high-reflective applications.

- Q: I heard that clay pots and aluminum cans are great caves for my fish to breed in but will the can rust???

- Aluminum okorder /

- Q: Is it safe or effective to use a hot plate for heating an aluminum coil?

- <p>Yes, you can use a hot plate to heat an aluminum coil, but with caution. Aluminum is a good conductor of heat, so it will heat up quickly. Ensure that the coil is clean and free from any residues that might cause uneven heating or damage. Monitor the temperature closely to prevent overheating, as aluminum can warp or melt at high temperatures. Use a heat-resistant surface or a heat diffuser to distribute the heat evenly and protect the hot plate surface. Always follow safety guidelines and manufacturer recommendations for both the hot plate and the aluminum coil.</p>

- Q: How are aluminum coils used in the production of cans and containers?

- Aluminum coils are used in the production of cans and containers as they are rolled into thin sheets that can be shaped into the desired form. These coils are fed into a machine where they are cut, formed, and joined together to create the body of the can or container. The lightweight and corrosion-resistant properties of aluminum make it an ideal material for packaging, ensuring the preservation and protection of the contents inside.

- Q: if air goes throught a lot of tiny aluminum will cause cooling? Why am i asking this because when you see inside the computer desktop has heatsink fan, and some of the heatsink are made by aluminum.

- Yes, aluminum is a great heat dissipater and is the primary material used for almost any heatsink.

- Q: How do aluminum coils contribute to the electrical conductivity of products?

- Aluminum coils contribute to the electrical conductivity of products due to their excellent electrical conductivity property. When electrical current is passed through aluminum coils, they allow the flow of electrons with minimal resistance, enabling efficient transmission of electricity and enhancing the overall conductivity of the product.

Send your message to us

3/8 Aluminum Coil - Mill Finished Direct Casting Aluminum Circle AA1050

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords