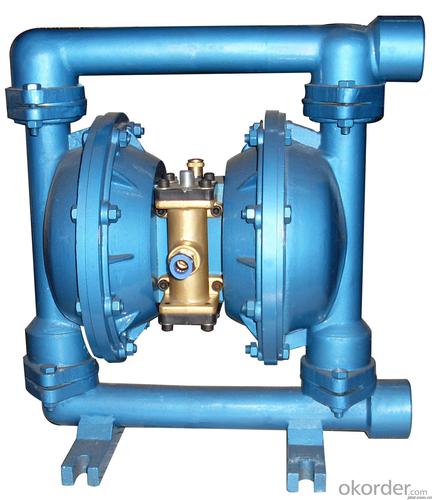

Diaphragm Metering Pump Air Driven Pump With Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Diaphragm Metering Pump Air Driven Pump

Features:

QBK Pneumatic Diaphragm Pumps also called Air Operated Double Diaphragm Pumps (AODD Pump) are rugged and durable self-priming, double diaphragm pumps, can handle any products that pours, from clean water to highly viscous, abrasive and chemically materials.

♦ Simple structure, easy to use and maintenance, less wearing parts. It can be working under liquid and running dry as well.

♦Suction up to 5m, max discharge pressure is 7bar, max grain diameter is 10mm, max liquid viscosity is 10,000C.s.t.

♦ Material: PP, Aluminum, Cast Iron, Stainless Steel. Diaphragm material: NBR, Viton, Teflon, FEP etc.

♦ Flow rate can be controlled from zero to max flow by increasing or decreasing air pressure.

Specification:

Model | Diameter (mm) | Max Flow (L/min) | Suction (m) | Max Discharge Pressure (Bar) | Max Grain Dia (mm) | Max Air Consumption (L/min) |

QBK-8 | 8 | 16 | 5 | 6.9 | 1 | 300 |

QBK-10/15 | 10/15 | 20 | 5 | 6.9 | 1 | 300 |

QBK-25 | 25 | 100 | 5 | 6.9 | 2.5 | 600 |

QBK-40 | 40 | 140 | 5 | 6.9 | 4.5 | 600 |

QBK-50 | 50 | 240 | 5 | 6.9 | 8 | 900 |

QBK-65 | 65 | 280 | 5 | 6.9 | 8 | 900 |

QBK-80 | 80 | 400 | 5 | 6.9 | 10 | 1500 |

QBK-100 | 100 | 480 | 5 | 6.9 | 10 | 1500 |

APPLICATION:

1. The pump can suck various wedge water, cement slurry and mortar etc.

2. The pump can suck various strong acid, alkali and corrosive liquid etc.

3. It can be used as a front-step tranmission device of the solid and liquid separation equipment.

Picture Shows

- Q: Does the water pump and the circulating pump belong to the centrifugal pump?

- As long as the flow and head to meet what pump can be, the general centrifugal pump applications are more.

- Q: how do u know when u need to replace ur water pump or how do u know when its not working??? thanks

- i like the way you said that.h2o pump.well if the water pump isnt working like it should,then it will overheat and the temp.light will come on and also if its leaking anti-freexe,its time to change it.also if the bearing is making a racket,it is time for a new 1.

- Q: are there any pumps that can save energy more? Environmental protection is necessary and the price is not high.

- Water pump. ( Pond ) Sump pump. ( Flood prevention ) Auto water pump. ( Radiator ) What is the specific purpose of the pump.

- Q: the pump is pumping hot wtaer from the hot water tank around the domestic hot water system, i.e to taps and shower.

- These pumps can have their own bearing or they may rely on the bearings in the motor. Most of these are anti-friction bearings that have a limited life. Also if the pump runs dry it can over heat and seize.

- Q: Can I charge the battery (1.2Vx2) with the suction tube submerged in the water or do I have to remove the suction tube every time I have to charge the battery?

- Since you don't mention the model of the pump, if you can connect the charger with a dry connection, you should not have to remove the pump/tube. If you have to take the battery out, you stand the risk of dropping it in the water putting it back, but obviously (I think) you don't have to remove the pump/tube.

- Q: Hi, what is the difference between an Air pump and a Water pump. What are the functions of each? Does a tank filter come with an air pump? Is an Air pump or Water pump required?

- If you have a water pump filter that hangs on the side of the tank you do not need an air pump alhtough I would have both. The water gets oxygen from being circulated. An air pump usually comes with a starter tank along with a air stone. This pump puts oxygen into the water for the fish which should be 1 fish per galllon.

- Q: i hear water swirl in my dash board when i take off and when i reverse, i heard its the water pump pushing water through the heater core, but how can i fix it.?

- The issue is not just that the water pump is pumping air through the system, it is that there is an issue with air being in there in the first place. It gets there one of two ways. First, your cooling system is losing water somewhere and air is getting drawn in through the coolant overflow bottle or through a leak in the hoses, the radiator, or the radiator cap. Second it is getting in through a compression leak. Compression leaks are caused by blown head gaskets or cracked or corroded cylinder heads or engine blocks. You need to determine which it is, because you need to address the issues differently. Fill the cooling system with coolant, purge the air out of it, and connect a pressure gauge to the radiator where the cap normally goes. Start the engine. If the gauge fluctuates up and down, you have a compression leak caused by a blown head gasket or crack in the block or head. If the gauge doesn't fluctuate, you have a leak in the cooling system that could be in any one of many places, such as hoses, caps, freeze plugs, the radiator itself, the heater core, or one of many gaskets. If it turns out to be a compression leak, you need to pull off the heads and replace the gaskets, and if there is any corrosion or cracks, you need to either replace or repair the heads. Broken head bolts can also allow compression leaks, so if you do remove the heads, you need to replace the bolts and torque them to the correct specs. If your engine oil looks frothy, like latte, this is another sign that you have a blown head gasket. It means coolant is getting into the engine oil. If it is a leak in the cooling system that is not related to the head gasket, you need to find it and seal it. There is no other way to find out exactly what is allowing air into your cooling system other than these two methods. The sound you hear when water is flowing through your heater core is actually the air gurgling through. No air, no sound.

- Q: I have a 2000 dodge 1500 the water pump is leaking and the belt is real squeaky. Are these related?

- yes they are related the belt squeaking means its probably slipping or coolant from the leaking pump is getting on the belt so fix the pump and go ahead and change the belt since it will be off anyway

- Q: The water hose hooks from the radiator to the water pump. Does an o-ring go in it? What else could be causing it to leak?

- Hello, okorder . Watch The Video! You will be glad you did! Thanks for your time! BimmerFix Products Co. Tucson, Arizona, USA

- Q: I have some black RTV silicone that I got with a gasket for my oil pan. Can I use some on a gasket for a water pump instead of regular sealant or is there a particular type I need? If there is a certain or preferred type please give me a link to it at like autozone or something, thanks!

- autozone sells parts..dont fix cars. black works fine on water pump. and you do use silicone with gaskets on certain applications. Water pump especially (unless you enjoy doing things twice). a light layer to hold the gasket in place! otherwise it will never line up. I use either black or gray whenever i need to make a gasket or install a w//p

Send your message to us

Diaphragm Metering Pump Air Driven Pump With Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords