Diamond Plate Aluminum Sheets - Aluminium Profiles Thermal Barrier SAD601

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Profiles Thermal Barrier SAD601 Description:

Aluminium Profiles Thermal Barrier SAD601(also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profiles Thermal Barrier SAD601:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

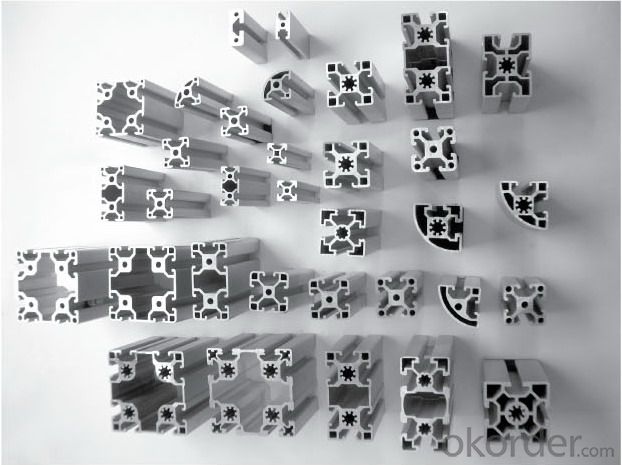

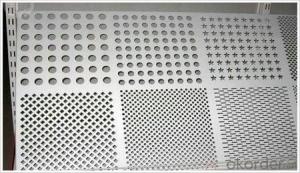

3.Aluminium Profiles Thermal Barrier SAD601 Images:

4.Aluminium Profiles Thermal Barrier SAD601 Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different methods of forming aluminum sheets?

- There are several methods of forming aluminum sheets, including rolling, extrusion, and stamping. Rolling involves passing the aluminum through a series of rollers to reduce its thickness and create a uniform sheet. Extrusion involves pushing the aluminum through a die to create a specific shape or profile. Stamping involves using a mold or die to press the aluminum into a desired shape or pattern.

- Q: 6061 what is the density of the aluminum plate?

- 6061 aluminum plate density:6061 aluminum plate is aluminum alloy, the density is calculated according to 2.9g/cm3.Calculation method:Aluminium plate weight (kg) =0.0000029 * * * * width * lengthAluminium tube weight (kg) =0.0000029 * wall thickness * (outside diameter wall thickness) * lengthFormula for weight calculation of aluminium bars (kg) =0.0000029 * radius * radius * length

- Q: Can the aluminum sheets be used for manufacturing food packaging?

- Yes, aluminum sheets can be used for manufacturing food packaging. Aluminum is a popular choice for food packaging due to its various properties. It is lightweight, resistant to corrosion, and has excellent heat conductivity. These qualities make it suitable for preserving the freshness and quality of food products. Additionally, aluminum is impermeable to light, moisture, and oxygen, which helps in extending the shelf life of food. Furthermore, aluminum sheets can be easily molded into different shapes and sizes, allowing for customized packaging solutions. Overall, aluminum sheets are commonly used in the food packaging industry due to their versatility, durability, and ability to maintain the safety and integrity of food products.

- Q: I get to do an aluminum blank for a fence and I am curious whether I can put slots in it with the router?I am not sure how thick it is, may say 3/16's.

- Yes you can use a router on aluminium. Use some kind of a fence, a piece of angle iron or a block of hardwood. Use a new bit, an old dull one will cause you problems. Pre-drill smaller holes than the slot width at each end of the slot. Stay back away from the end of the slot about 1/32 of an inch. Make several passes, at a depth of about 1/16 of an inch, per pass. If you can, make the slot with a bit smaller than the finished slot width. Use a 3/16 bit for a 1/4 inch slot. Use a 5/16 bit for a 3/8 inch slot. This will give cleaner slot edges and allow you to accurately make the slot width that you want. You can do this dry, but a little WD-40 oil will give even cleaner slot edges. Also climb mill the last pass on each slot edge to give a better/ smother edge. Climb Milling is pushing the router backwards of the way you normally travel in wood. Ben

- Q: Which kind of material does aluminum sheet(aluminum oxide) belong to?

- it's metal and belongs to hardware

- Q: What are the physical properties of aluminum sheets?

- Aluminum sheets possess various physical properties that make them highly desirable in numerous applications. Firstly, aluminum sheets are lightweight, with a density of around 2.7 grams per cubic centimeter, which is about one-third that of steel. This characteristic makes aluminum sheets easy to handle and transport, reducing overall weight in structures or products. Aluminum sheets also exhibit excellent corrosion resistance due to the formation of a thin, protective oxide layer on their surface when exposed to air. This oxide layer acts as a barrier, preventing further oxidation and corrosion, making aluminum sheets suitable for outdoor applications and environments with high humidity or exposure to corrosive substances. Furthermore, aluminum sheets have good thermal conductivity, allowing them to efficiently transfer heat. This property makes aluminum sheets commonly used in heat exchangers, radiators, and other cooling systems. Another important physical property of aluminum sheets is their high electrical conductivity. Aluminum is an excellent conductor of electricity, second only to copper, making it widely used in electrical applications such as wiring, power transmission lines, and electrical equipment. In terms of appearance, aluminum sheets have a bright, silvery-white color and a smooth surface finish, giving them an aesthetically pleasing look. They can be easily shaped, formed, and machined, making aluminum sheets highly versatile and suitable for various manufacturing processes. Overall, the physical properties of aluminum sheets, including their lightweight nature, corrosion resistance, thermal conductivity, electrical conductivity, and ease of fabrication, contribute to their widespread use in industries such as aerospace, automotive, construction, and electrical engineering.

- Q: What are the standard sizes and availability of aluminum sheets in the market?

- The standard sizes and availability of aluminum sheets in the market can vary depending on the location and specific requirements. However, there are some commonly available sizes that can generally be found in most markets. In terms of thickness, aluminum sheets are commonly available in 0.02 to 0.2 inches (0.5 to 5 millimeters) thickness range. Thinner sheets (0.02 to 0.06 inches) are often used for lightweight applications such as signage or crafts, while thicker sheets (0.1 to 0.2 inches) are typically used for more heavy-duty applications like construction or industrial purposes. Regarding width and length, standard aluminum sheet sizes are often offered in 4 feet by 8 feet (48 inches by 96 inches) or 4 feet by 12 feet (48 inches by 144 inches). These dimensions are widely available and suitable for various applications. However, it's important to note that custom sizes can also be ordered or cut from larger sheets to meet specific project requirements. Availability of aluminum sheets can be found in various locations, including local hardware stores, metal suppliers, and online marketplaces. It is always recommended to check with local suppliers or conduct online research to determine the specific sizes and availability in your area. Additionally, different grades or alloys of aluminum may have varying availability, so it's essential to consider the specific requirements of your project when sourcing aluminum sheets.

- Q: How many square meters does the aluminum plate engrave?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet. If you have any questions, please ask, thank you.

- Q: Are there any formulators out there that have any ideas on putting together a cleaner that removes carbon (baked on grease) from an aluminum pan without attacking the meatal itself?? Ive been thinking about this problem for a while and would appriciate any ideas you guys might have. Thanks

- try GOJO hand cleaner with a Sung. you dont need to scrub hard and it will remove the baked on grease.

- Q: This question asks about the typical duration an aluminum roof sheet can last before it needs to be replaced or repaired.

- <p>The lifespan of aluminum sheets for roofing can vary depending on the quality of the material, installation, and environmental factors. On average, a well-maintained aluminum roof can last between 20 to 50 years. High-quality aluminum roofing materials, when properly installed, can even exceed this range, offering a lifespan of up to 70 years. However, it's important to note that regular inspections and maintenance are crucial to extend the life of any roofing material, including aluminum.</p>

Send your message to us

Diamond Plate Aluminum Sheets - Aluminium Profiles Thermal Barrier SAD601

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords