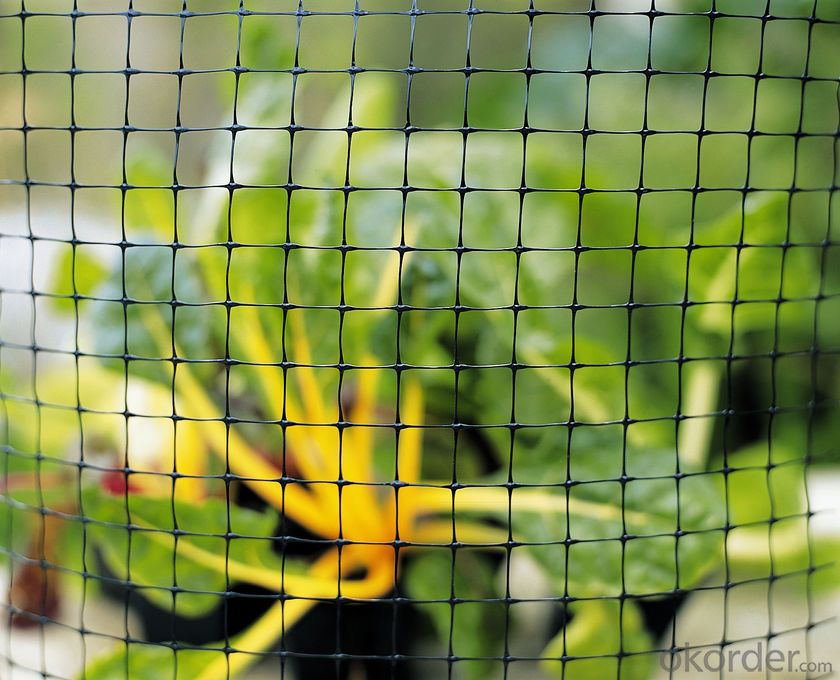

Deer Guard Fence, Extruded PP Deer Guard Netting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic netting plastic mesh breeding mesh

1. Plastic Plain Netting

Colour:white,black,blue and green, client's requirement.

2. Deer fence introduction:

Deer fencing is a very high strength, lightweight, 3.6ft to 7.3ft high deer fence manufactured from high strength polypropylene BOP plastic netting. Deer have a tendency to forage over large areas and the cost effective deer fencing offers a very effective deer control barrier.

The deer fence is black, UV stabilised and rot proof and unobtrusive as it merges into it's background. Deer fencing is very quick and easy to erect and each roll weighs less than 15kg. The Deer Netting should be installed by battening to the fencing posts to ensure the mesh filaments are not damaged.

3. Features of the deer neeting fence:

Deer fence is easy to erect and install

Plastic netting has a mesh hole size of 0.06" ,0.08",0.18",0.19"

The BOP plastic netting has a high tensile strength

Plastic mesh is UV stabilized and chemical resistant

Deer fencing rolls are lightweight

Deer fencing is a very high strength, lightweight 1.8m high Deer fence manufactured from polypropylene.

Deer fencing net is supplied on a 100m long roll

4. Features:

1). Low cost, while has superior strength

2). Has anti-tearing and friction capability

3). Wide range of product availability, some other mesh sizes and weights can also produced as per customers' requirements.

5. Package/Payment/Delivery:

Package: Usually packed by rolls in plastic film bags with labels inside and then loosely loaded in the container

6. FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Can geotextiles be used in geogrid reinforcement applications?

- Yes, geotextiles can be used in geogrid reinforcement applications. Geotextiles are often used in combination with geogrids to enhance their performance and provide additional benefits such as soil separation, filtration, and erosion control.

- Q: After the laying of drainage board and then need to lay a layer of geotextile it?

- After the laying of drainage board and then need to lay a layer of geotextile it?

- Q: Who knows geotextile, how to sew, the best video

- Where do you use it? Professional production geotextile manufacturers to answer,

- Q: How do geotextiles improve soil stability?

- Geotextiles improve soil stability by providing reinforcement and separation. They prevent soil erosion, retain moisture, and distribute loads, ultimately enhancing the overall strength and stability of the soil.

- Q: What are the disadvantages of using geotextiles?

- One of the main disadvantages of using geotextiles is their potential for clogging and reduced permeability. Over time, fine particles and debris can accumulate within the geotextile, leading to reduced water flow and drainage. Additionally, improper installation or lack of maintenance can cause geotextiles to shift or tear, compromising their effectiveness. Moreover, geotextiles may not be suitable for all soil conditions or applications, as they may not provide adequate stability or strength in certain situations.

- Q: What are the applications of geotextiles in landscaping?

- Geotextiles have several applications in landscaping, including erosion control, soil stabilization, and weed suppression. They are commonly used to prevent soil erosion on slopes by providing a stable base for plants and preventing the loss of topsoil. Geotextiles also help to stabilize the soil by distributing the weight of heavy objects, such as rocks or pavers, and preventing them from sinking into the ground. Additionally, they can be used as a barrier to prevent weed growth, reducing the need for herbicides and manual weeding.

- Q: How are geotextiles used in coastal engineering?

- Geotextiles are commonly used in coastal engineering to stabilize and protect coastlines. They are placed beneath coastal structures or along the shoreline to prevent erosion, reduce wave impact, and enhance sedimentation. Geotextiles act as a barrier, preventing the loss of soil while allowing water to pass through, thereby minimizing the negative effects of waves and tides on the coastline. Additionally, they provide a stable foundation for coastal structures like revetments, breakwaters, and seawalls, helping to maintain their integrity and longevity.

- Q: What are the maintenance requirements for geotextile-reinforced retaining walls?

- The maintenance requirements for geotextile-reinforced retaining walls typically include regular inspections to check for any signs of damage, erosion, or settlement. Additionally, it is important to ensure that the drainage system is functioning properly to prevent water accumulation behind the wall. Any necessary repairs or adjustments should be promptly addressed to maintain the structural integrity of the retaining wall.

- Q: Geotextile exports Nordic need certification

- Production standards geotextile, geomembrane, composite geomembrane.

- Q: Do you have a geotextile bed?

- Filament geotextile can, short silk toxic, I produce geotextile materials

Send your message to us

Deer Guard Fence, Extruded PP Deer Guard Netting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords