Tcs Geotextile Deer Guard Fence Netting / Extruded PP Tcs Geotextile Deer Guard Fence

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic netting plastic mesh breeding mesh

1. Plastic Plain Netting

Colour:white,black,blue and green, client's requirement.

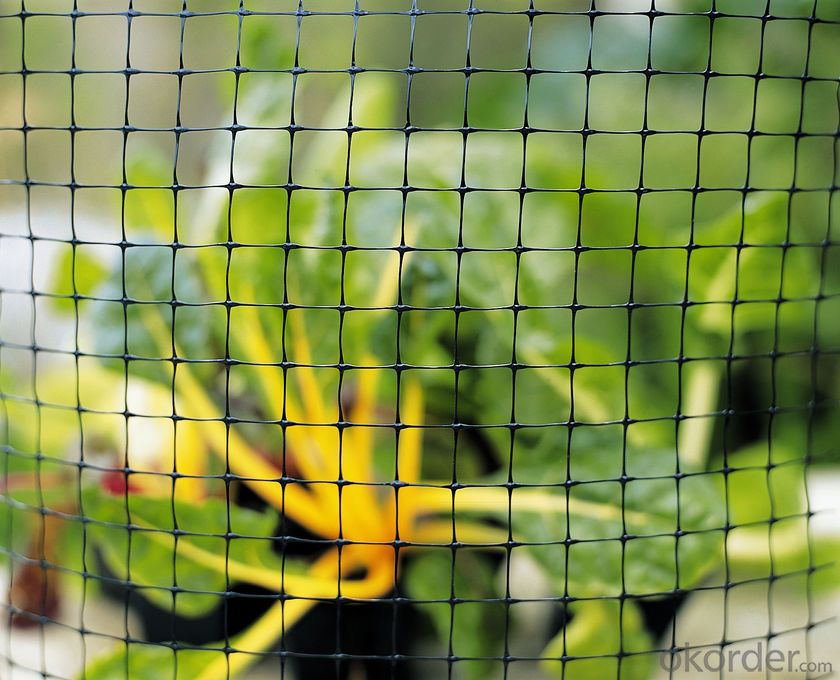

2. Deer fence introduction:

Deer fencing is a very high strength, lightweight, 3.6ft to 7.3ft high deer fence manufactured from high strength polypropylene BOP plastic netting. Deer have a tendency to forage over large areas and the cost effective deer fencing offers a very effective deer control barrier.

The deer fence is black, UV stabilised and rot proof and unobtrusive as it merges into it's background. Deer fencing is very quick and easy to erect and each roll weighs less than 15kg. The Deer Netting should be installed by battening to the fencing posts to ensure the mesh filaments are not damaged.

3. Features of the deer neeting fence:

Deer fence is easy to erect and install

Plastic netting has a mesh hole size of 0.06" ,0.08",0.18",0.19"

The BOP plastic netting has a high tensile strength

Plastic mesh is UV stabilized and chemical resistant

Deer fencing rolls are lightweight

Deer fencing is a very high strength, lightweight 1.8m high Deer fence manufactured from polypropylene.

Deer fencing net is supplied on a 100m long roll

4. Features:

1). Low cost, while has superior strength

2). Has anti-tearing and friction capability

3). Wide range of product availability, some other mesh sizes and weights can also produced as per customers' requirements.

5. Package/Payment/Delivery:

Package: Usually packed by rolls in plastic film bags with labels inside and then loosely loaded in the container

6. FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Waiting to cooperate with you!

- Q: What is the role of permeability in geotextiles?

- The role of permeability in geotextiles is to allow the passage of water or other fluids while restraining the movement of soil particles. It helps in drainage and filtration processes, preventing the buildup of excess moisture and maintaining the stability and integrity of the surrounding soil or substrate.

- Q: How do geotextiles help in preventing the growth of weeds?

- Geotextiles help in preventing the growth of weeds by acting as a physical barrier between the soil and the environment. These synthetic fabrics are placed over the soil, suppressing weed growth by blocking sunlight, which weeds need for photosynthesis. Geotextiles also inhibit weed root penetration, preventing them from establishing a strong foothold in the soil. Additionally, the fabric allows water and nutrients to pass through, promoting healthy plant growth while suppressing weed development.

- Q: How do geotextiles contribute to soil consolidation?

- Geotextiles contribute to soil consolidation by providing reinforcement and stabilization to the soil. They act as a barrier between different soil layers and help distribute the loads evenly, reducing the risk of soil movement and settlement. Additionally, geotextiles can improve soil drainage and filtration, allowing excess water to flow through while retaining the integrity of the soil structure. Overall, geotextiles play a crucial role in enhancing soil consolidation and providing long-term stability to construction projects and civil engineering applications.

- Q: Are geotextiles suitable for use in gabion walls?

- Yes, geotextiles are suitable for use in gabion walls. Geotextiles can be used as a filter fabric to prevent soil erosion and improve the stability and longevity of the gabion wall structure. They help to control soil movement and provide additional reinforcement, making them a practical and effective solution for gabion wall construction.

- Q: How do geotextiles help in preventing the loss of fine particles in filter layers?

- Geotextiles help in preventing the loss of fine particles in filter layers by acting as a barrier that allows water to pass through while retaining the fine particles. They provide a stable and durable structure that supports the filter layer, preventing it from dislodging or eroding. This ensures that the filter layer remains intact and effectively filters out the fine particles, reducing their loss and improving the overall performance and longevity of the filtration system.

- Q: What is the use of the black network when the shop is paved?

- It is geogrid, can enhance the overall strength of the roadbed, from the role of tensile, mostly polyethylene materials.

- Q: How do geotextiles contribute to slope stability analysis?

- Geotextiles play a crucial role in slope stability analysis by providing reinforcement and soil stabilization. They are often used to improve the internal strength and mechanical properties of soils, preventing erosion and maintaining slope integrity. Geotextiles act as a barrier, distributing loads and reducing the potential for soil movement. Their high tensile strength helps in reinforcing slopes and retaining walls, increasing overall stability and reducing the risk of slope failure.

- Q: Can geotextiles be used in coastal erosion control in beach nourishment projects?

- Yes, geotextiles can be used in coastal erosion control in beach nourishment projects. Geotextiles are commonly used as a protective barrier to prevent erosion and stabilize the shoreline. They can be placed under the sand or gravel layer in beach nourishment projects to enhance the stability and longevity of the beach, reducing the impact of wave action and promoting sediment retention.

- Q: How to calculate the volume weight of polypropylene nonwoven geotextile

- I professional production geotextile geomembrane and other materials, wish smooth

- Q: What are the benefits of using geotextiles in road construction?

- Using geotextiles in road construction offers several benefits. Firstly, geotextiles act as a reinforcement material, enhancing the strength and stability of the road. They help distribute the load from the traffic, reducing rutting and improving the overall durability of the road. Secondly, geotextiles prevent the mixing of different layers of the road, such as the subgrade and base, by acting as a separator. This prevents the contamination and weakening of the road structure. Additionally, geotextiles provide effective drainage, allowing water to pass through while preventing the clogging of soil particles. This helps in maintaining the road's stability and preventing water damage. Moreover, geotextiles can be cost-effective by reducing the need for expensive materials like aggregate, as they can be used to reinforce weak soils. Overall, the use of geotextiles in road construction can result in longer-lasting roads with reduced maintenance needs.

Send your message to us

Tcs Geotextile Deer Guard Fence Netting / Extruded PP Tcs Geotextile Deer Guard Fence

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords