Decosub White Mill Finish Embossed Five Bar Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Embossed Five Bar Aluminum Sheet

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Mill Finish Embossed Five Bar Aluminum Sheet

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Embossed Five Bar Aluminum Sheet

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

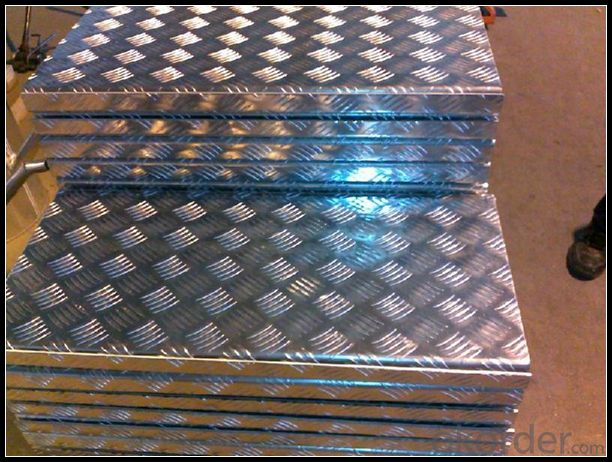

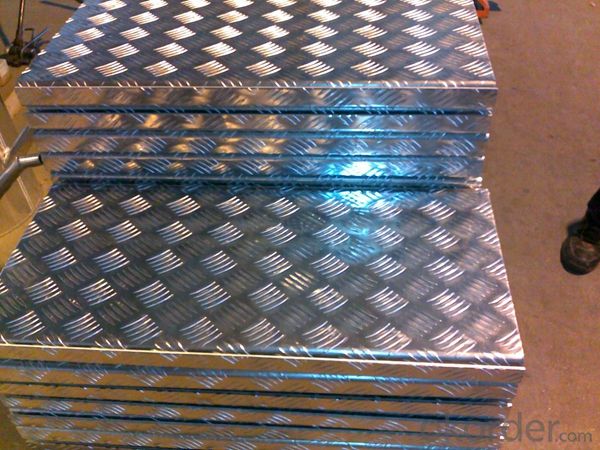

5. Image of Mill Finish Embossed Five Bar Aluminum Sheet

6. Package and shipping of Mill Finish Embossed Five Bar Aluminum Sheet

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the potential hazards or risks associated with the use and handling of aluminum sheets?

- <p>Safety issues related to aluminum sheets include the risk of cuts and lacerations from sharp edges, potential for eye injuries if aluminum particles or dust comes into contact with the eyes, and the risk of fire or explosion if aluminum dust is present in the air and ignited. Additionally, improper handling can lead to back injuries or other musculoskeletal disorders due to the weight of the sheets. Inhalation of aluminum dust over a long period may also pose health risks, although it's less common. It's crucial to use proper protective equipment and follow safety guidelines when working with aluminum sheets.</p>

- Q: Can aluminum sheets be an alternative to ceramics in certain applications?

- Yes, aluminum sheets can be an alternative to ceramics in certain applications. Aluminum sheets offer several advantages over ceramics, such as being lighter in weight, more cost-effective, and easier to shape and fabricate. They also have excellent thermal and electrical conductivity properties, making them suitable for applications where heat dissipation or electrical conduction is required. Additionally, aluminum sheets can withstand high temperatures and have good corrosion resistance. However, ceramics still have their own unique properties and strengths, such as higher hardness, better chemical resistance, and superior insulation capabilities, which might be more suitable for certain specific applications. Therefore, the suitability of aluminum sheets as an alternative to ceramics would depend on the specific requirements and conditions of the application in question.

- Q: My understanding of the periodic table, the transitional metals all rust because the S shells are higher energy then the D shells. So all transitional metals have 2 valence electrons. (Roughly...some electrons like to move around and give different apparent charges.) So why does aluminum corrode if it doesn't have a 2+ charge?

- 'Rusting' commonly refers to the corrosion (oxidation) of iron so when talking about other metals, it is better to use the term 'corrosion' or 'oxidation'. Aluminum can corrode and the fact that it has a general oxidation number of +3 doesn't really matter. Many elements which have a charge that is different from +2 can oxidize. Alkali metals for instance (which have a charge of +1) can oxidize. Lithium can form lithium oxide (Li2O), sodium can form sodium oxide (Na2O) and so on. However, aluminum is known to be quite resistant to corrosion (oxidation) because it spontaneously forms a thin (solid) oxide layer at it's surface protecting it from further oxidation whereas iron, for an example, will easily lose that thin layer (it ''peels off easily'') exposing more iron to corrosion. So since Al has a +3 charge and O has a -2 charge, you'll need 2 atoms of Al and 3 atoms of O to make an electrically neutral compound. 2 atoms of Al = +6 charge 3 atoms of O = -6 charge Hence Al2O3 which is aluminum oxide. I hope it helps.

- Q: What is the cost of aluminum sheet compared to other metals?

- The cost of aluminum sheet compared to other metals can vary depending on various factors such as market conditions, availability, and specific metal grades. Generally, aluminum sheet is considered to be more affordable than many other metals such as stainless steel, copper, and brass. This is mainly due to the abundance of aluminum in the Earth's crust and the relatively low cost of extracting and refining it. Additionally, aluminum is often lighter in weight compared to other metals, making it a more cost-effective option for applications where weight is a concern, such as in the transportation industry. However, it is important to note that the cost of aluminum can fluctuate based on global supply and demand dynamics, tariffs, and other economic factors. Therefore, it is recommended to check current market prices and consult with suppliers or metal specialists for accurate and up-to-date pricing information.

- Q: How does the thickness tolerance of aluminum sheet affect its usability?

- The thickness tolerance of aluminum sheet plays a significant role in determining its usability. The thickness tolerance refers to the acceptable deviation from the specified thickness of the sheet. It is typically expressed as a range or a plus/minus value. A tighter thickness tolerance ensures that the aluminum sheet meets the desired specifications consistently. This is crucial for applications where precise dimensions are required, such as in aerospace, automotive, and construction industries. In these applications, even a slight deviation in thickness can negatively impact the performance and functionality of the product. For instance, in aircraft manufacturing, the thickness tolerance of aluminum sheets used for structural components is highly critical. A thin sheet might compromise the structural integrity, while a thicker sheet could lead to excess weight, affecting fuel efficiency. Similarly, in the automotive industry, precise thickness tolerance is essential for ensuring compatibility and fitment of various components. On the other hand, a looser thickness tolerance can be acceptable for applications where precise dimensions are not as critical. For example, in general fabrication, signage, or decorative purposes, a wider thickness tolerance may not significantly affect the usability or appearance of the aluminum sheet. Additionally, the cost of manufacturing aluminum sheets with tighter thickness tolerances is typically higher due to increased precision and quality control measures. Therefore, the required level of tolerance should be balanced with the intended use and cost considerations. In conclusion, the thickness tolerance of aluminum sheet directly affects its usability, particularly in industries requiring precise dimensions. It is essential to select the appropriate tolerance level to ensure the sheet meets the required specifications, maintaining the desired performance and functionality of the final product.

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum sheets as a roofing material.

- <p>Aluminum sheets for roofing offer several advantages, including durability, resistance to rust and corrosion, lightweight nature, and energy efficiency due to reflective properties. They are also easy to install and maintain, and can be recycled, making them environmentally friendly. However, there are some disadvantages such as being more expensive than some other roofing materials, potential for denting if not properly installed, and noise issues during heavy rain or hail due to their lightweight nature. Additionally, they may require more frequent replacement compared to some other materials.</p>

- Q: What are the different methods for finishing the edges of aluminum sheets?

- There are several methods for finishing the edges of aluminum sheets, including deburring, chamfering, filing, sanding, and using edge trims or edge guards.

- Q: This question asks for a comparison between aluminum sheets and other lightweight materials like plastic and glass, focusing on their properties and uses.

- <p>Aluminum sheets are lightweight yet strong, offering excellent strength-to-weight ratios. They are more durable and heat resistant compared to plastics, which can deform under heat and are less sturdy. Unlike glass, aluminum is less brittle and does not shatter, making it safer for certain applications. Additionally, aluminum is recyclable and has good thermal and electrical conductivity, which is not the case with plastics. However, plastics are generally cheaper and easier to shape into complex forms, while glass offers better transparency for applications requiring clear visibility. Each material has its advantages depending on the specific requirements of the application.</p>

- Q: Can the aluminum sheets be used for packaging applications?

- Yes, aluminum sheets can be used for packaging applications.

- Q: Can aluminum sheets be painted after installation?

- Yes, aluminum sheets can be painted after installation.

Send your message to us

Decosub White Mill Finish Embossed Five Bar Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords