DC Solar Water Submersible Pump for irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 3000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of solar pumps.

CNBM Solar Water Pump is the pumping facility driven by solar energy, which consists of a solar pumping inverter and a pump. Solar water pumps kit is called solar pumping system combining with solar arrays designed according to different head and daily water flow for application. System is widely utilized for agriculture irrigation,desert control,pasture animal husbandry,city landscaping,daily water supply, etc.

In recent years, with the development of photovoltaic products from city application to huge demands of agriculture,pasture,desert areas, CNBM Solar Pond Pump has become the leading products combining photovoltaic industry with traditional industry such as agriculture water conservancy,desert control,daily water supply,city landscaping, etc.

CNBM Solar Pump driven by infinite solar energy, works from sunrise, and stops at sunset, need no connection to grid power nor diesel oil and battery. System can irrigate directly or store water instead of electricity in a reservoir. Solartech Solar fountain Pumps works with sprinkling irrigation, drip irrigation and infiltrating irrigation facilities, can be more efficient for water saving and dramatically lower the cost of using fossil energy.

2. Technical Function

1> High efficient DC brushless motor requires less solar array. Rich social benefits.

2> Optional centrifugal pump for big flow and helical rotor pump for high lift.

3> High efficient semiconductor device used in main circuit. High reliability. Up to 98% conversion efficiency of controller.

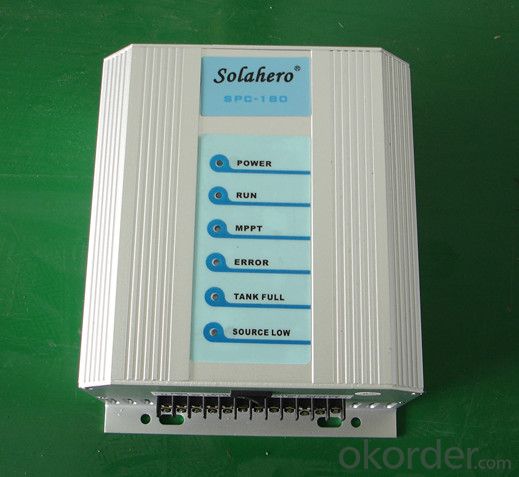

4> Independent intellectual property of dynamic VI maximum power point tracking (MPPT) algorithm. Fast response and good stability. 99% MPPT efficiency.

5> Full automatic operation. Complete protection functions. Integrated with water level monitor to prevent

overflow and dry running.

6> Full aluminum alloy case. IP52 protection grade. Ambient temperature: -20~+60℃.

Product Specifications

3. Specification details.

1> Flow: 0.4m³/h~22m³/h

2> Head: 10m~210m

3> Power: 0.1~3Kw

4. FAQ

1> May we ask if the bare pump or the whole pump system would be all right for you to arrange the delivery?

The bare pump and the who systems would be all acceptable at your side. A controller will be equipped with the pump freely. Regarding the whole system, we can also make the best solar panels configuration according to your requirements.

2> Does your controller have the MPPT Function?

Yes, our controller have. This would be not a problem.

3> Can your pump work automatically?

Yes, it would be the basic advantage of solar water pumps.

- Q: I need information about basic water pumps. I'll have to build a mechanical one for school. Do you have any ideas, information, designs, links? Thanks!

- A very simple and old design for a water pump is called the ball-chain or bucket-chain pump. A google search should show you what they are. Building one should be fairly straightforward and simple.

- Q: My 2005 Lexus IS300 is close to 90K miles and I believe the timing belt/water pump should be replaced. I have priced this with several dealers and mechanics and at this time I can't afford close to $1000 to have this done. However, I see there are kits that can be purchased for about $400.Can a DIY'er with above average mechanical experience replace the belt nd pump relatively easily?

- The fact that you've posed that question here is a pretty fair indicator that you will NOT have an easy time trying to do this work. And actually $1k is not a bad price for this type of repair. If you make a mistake while performing this work yourself the consequences could be very, very severe, i.e., completely blowing your engine. If I were you, I'd rely on public transportation until I could save the requisite $1k to have a shop do the repair.

- Q: It is known that it takes an hour to pump water, and also to know the head. How does the pump power need to be calculated? What's the formula?

- A 15kw pump, know how to calculate the head pumping water for an hour (if the head is 10 meters)Lift: MFlow rate: kg / sec (general water pump is cubic / hour, if 10 cubic hour / hour: 2.7 kg / sec)Efficiency: average 60%15000/102*0.6=88 kilograms per second88/10=8.8 kg / sec8.8*3600=31680 kg / h=31.6 cubic / hour

- Q: I think the water pump is going out in my truck can I still drive it short distance if I put water in it first?

- If the temperature gauge is working and the water isnt leaking and its full just drive it no more than 10 minutes at a time or until the temperature gauge reads hot then let it cool off and repeat. DO NOT POUR COLD WATER IN A HOT MOTOR, you will crack the heads!

- Q: I have a 1999 Chrysler LHS. Recently, the water pump started leaking and it ruined the timing belt. I brought it to a mechanic that I've never used before, so I have no idea how reliable they are. They now told me that my brake lines blew. Can the leaking water pump also cause brake lines to rot?

- Very doubtful. Even getting anti-freeze on a timing belt should not ruin that. If you had no idea when it was last changed, and it showed signs of cracking, then it would be a good idea to replace it. Make sure to retain mileage records of when it was done. Did he specifically say the brake line rot was related? There are metal lines leading out to the suspension points and then rubber reinforced hoses for the last foot to 18 inches to the backing plate/brake caliper. Usually the rubber line is the first to go. The metal lines can last many decades.

- Q: can stress from to much weight cause the engine to get hot and cause your water pump to leak out the weep hole? and what else causes it to leak?

- There is a number of reasons for your water pump to leak. One could be its tear and wear due to years of used. Second is due to successive overheating. Weight cant cause water pump breakdown, as long as it does not overheats. To much pressure in the cooling system cause its breakdown. Hope this might help!

- Q: I suddenly have this rattle noise whenever the engine is running but it diminishes with speed. It almost sounds like spark knock but spark knock would get worse at speed. It could be the water pump. Would a water pump get louder with speed, or go away as this does? I feel a tiny bit of in-out motion in the shaft but not side to side. Car is a Geo Metro and does have hydraulic lifters.

- sounds like a pulley or bearing noise

- Q: How can I test to be sure my water pump is working before I go to the lake and burn up my motor. `72 65hp johnson. thank you.

- You can also go to a marina and buy earmuffs that hook to a garden hose and fit over your water intake. As stated above just look for a stream of water coming out the back of the engine.

- Q: implementation of regulator in water level control system

- This might be explained with an example. There is a water tank being used by a community (or a dwelling) and it is supplied by a pump from a well. There is a switch in the tank that is wired to the pump motor. The switch is activated by a lever attached to a float in the tank. When the float is in the down position the pump runs, When the float is pushed up by the water the punp is turned off. The pump first operates and fills the tank and then shuts off when the tank is full. When the usage of water drops the water in the tank to a certain level, the pump turns on until it is full again. The float, the switch and the motor are the pump regulating devices. This type of regulation is called two-position, like a light switch. Other more involved types of regulation may adjust a valve in the pipeline from the pump . This changes the rate of flow while the pump continues to run. The first type of regulation can be called digital because the flow is yes or no. The second can be called analog because while it is on, the flow varies in amount. If I have not adequately answered your question, maybe someone else will.

- Q: Water pump 50HZ impeller and 60HZ what is different, why not the same?

- 50HZ motors are usually not damaged if they run on a 60HZ circuit, but the speed will increaseConversely, the 60HZ device runs on the 50HZ circuit, and the speed drops.Because of their different frequency, make them synchronous speed rotating magnetic field winding is different, so the rotor induction (induction motor) speed will be different, the pump will naturally lift Gao Shaoxu, and often will not cause damage to the equipment, because many things are in the 50HZ 60HZ.Second, for synchronous motors, the increase and decrease of speed is much more obvious than that of induction motors, because their rotor and motor are synchronous and keep synchronous speed

Send your message to us

DC Solar Water Submersible Pump for irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 3000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords