Aluminum Sheets in Tennessee - DC/CC China Cheap Price 1060 1100 O Aluminum Disc for Turkey Barrels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

We are able to supply 1,2,3,5,6,8 series alloy coil, foil and sheets, including 1***, 3***, 3104, 5052, 5182, 5754, 5083,5086,8011,8079

Our products include:

1). Mill-finished aluminum coil:

Alloy: AA1050, 1060, 1100, AA3003, 3005, 3015, 5052, 5754, 5083,8011 ,8079etc.

Temper: H14/16/18/22/24/32, HO etc.

Thickness: 0.08mm—100mm

Width: 100mm—2200mm (Can be slitted)

Notice: Embossment can be done if required.

2). Color-Coated Aluminum Coil:

Alloy : AA1050/1100/3003/3005/3105/5005/5052/8079 etc.

Thickness: 0.03mm—1.50mm

Width: 10mm—1600mm (Can be slitted)

Coating : PVDF, PE

Coating thickness: Usually 16-25 micron, could be33-40 micron

Color : According to customers’ requirements

Notice : Embossment can be done if required

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

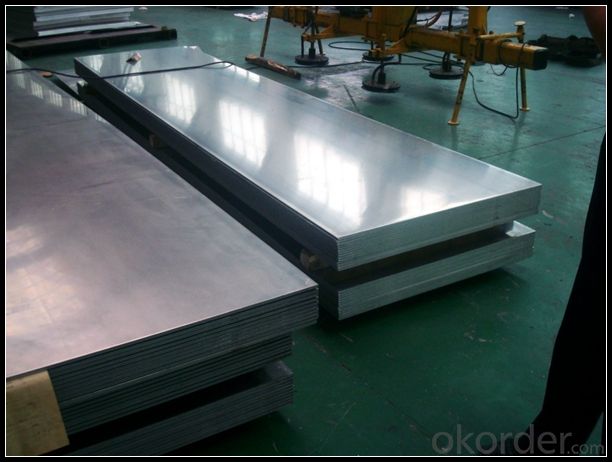

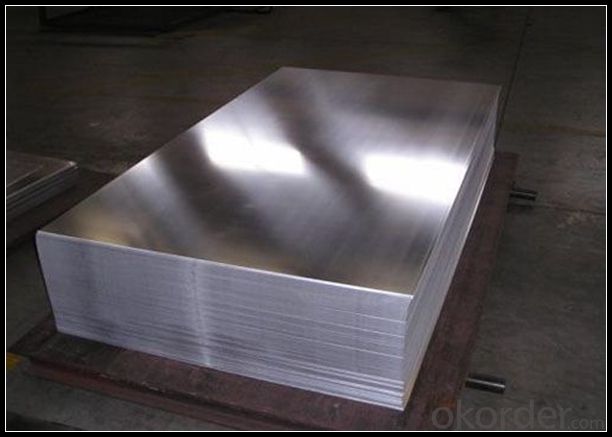

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc |

- Q: Q. Calculate the number of aluminium ions present in 0.051 g of aluminium oxide.( Hint: The mass of an ion is the same as that of an atom of the same element. Atomic mass of Al = 27 u) Please Explain each and every step!!!Thankx..A lot !!

- The formula for aluminium oxide is Al2O3 Its molecular weight is 2*27+3*16= 54+48 =102 Now, 102g of Al2O3 contains 2*6.023*10^23 number of Al ions so 1g contains (2*6.023*10^23)/102 number of Al ions so 0.051g Al2O3 contain (2*6.023*10^23)/102 *0.051 number of Al ions which is equal to 6.023*10^23*10^-3 = 6.023*10^20 number of Al ions(Answer)

- Q: What are the different methods of surface coating aluminum sheets?

- There are several methods of surface coating aluminum sheets, including anodizing, powder coating, paint coating, and electroplating.

- Q: Can 101 aluminum sheets be bent or formed into different shapes?

- Certainly! It is indeed possible to bend or shape 101 aluminum sheets into various forms. Aluminum possesses high malleability, meaning it can be shaped effortlessly without any risk of breaking or cracking. The specific grade of aluminum, such as 101, signifies the alloy composition and might possess specific properties that make it more suitable for bending and shaping. Nevertheless, the capacity to bend or shape aluminum sheets also relies on their thickness; thicker sheets may necessitate greater force and specialized equipment. In conclusion, with the correct tools and techniques, it is feasible to bend or shape 101 aluminum sheets into diverse shapes to fulfill specific requirements.

- Q: To rephrase- in our physics class we found that a simple bar magnet wouldn't attract to an aluminum gutter nail, but our teacher told us to find out whether or not any magnet could lift up the aluminum material. If you answer please give a reference or source, or at least an idea on how to go about researching this, all help appreciated, thanks and God Bless!

- Aluminum Magnet

- Q: Who knows the ceiling size of aluminum hang-parcel?

- Size of aluminum buckle plate: general size for home decoration: 300mm×300mm、300*450mm.300*600mm, general size for engineering: 600*600mm、800*800mm、 300*1200mm、600*1200mm. aluminum buckle plate takes aluminum alloy as base and is formulated by rough shape cutting, angle of shear and compression moulding forming. We use various coating to process aluminum buckle plate’s surface, generating aluminum buckle plate products. There are two types aluminum buckle plates: one is integrated aluminum buckle plate for home decoration, another is engineering aluminum buckle plate. With the feature of various colors, good for decoration and good weather resistance, aluminum buckle plate is broadly used for outdoor wall decoration, indoor top grade home decoration and advertisement decoration,etc.

- Q: What kind of aluminum sheet is most suitable for constructing the exterior walls of a building?

- <p>The best type of aluminum sheet for building exterior walls is typically aluminum composite material (ACM) or aluminum coil coated with a protective layer. ACM is lightweight, durable, and offers excellent resistance to weather and corrosion. It also provides good thermal insulation and is easy to install. Coated aluminum coils are often used for cladding due to their strength, low maintenance, and longevity. The choice may also depend on specific project requirements, such as aesthetic considerations, budget, and local climate conditions.</p>

- Q: What is the maximum width available for aluminum sheets?

- The maximum width available for aluminum sheets varies depending on the supplier and the specific requirements. However, standard widths for aluminum sheets typically range from 36 inches to 72 inches.

- Q: What is the final concentration of aluminum cation?

- You have to be able to determine the number of moles of Al+3 that each solution contributes to the final solution: 1. aluminum chloride: AlCl3 Multiply the volume (in L) by the molarity to determine the number of moles of each compound dissolved in solution. 0.0431 L x 0.279 M = 0.0120 mol AlCl3 in solution When the AlCl3 in placed in the water, it dissociates to form the following ions: AlCl3 -- Al+3 + 3Cl- So for every one mole of AlCl3 placed in the water, one mole of aluminum ions will dissociate. Therefore, since we have 0.0120 mole of AlCl3 in the solution, that means that the aluminum chloride will contribute 0.0120 Al+3 ions to the final solution. 2. Aluminum sulfate: Al2(SO4)3 Multiply the volume (in L) by the molarity to determine the number of moles of each compound dissolved in solution. 0.0146 L x 0.464 M = 0.00677 mol Al2(SO4)3 in solution When the Al2(SO4)3 in placed in the water, it dissociates to form the following ions: Al2(SO4)3 -- 2Al+3 + 3(SO4)-2 So for every one mole of Al2(SO4)3 placed in the water, two mole of aluminum ions will dissociate. Use the mole ratios of the dissociation reaction to determine the number of moles of Al+3 ions that the aluminum sulfate contributes to the solution. 0.00677 mol Al2(SO4)3 x (2 mol Al+3 ions / 1 mol Al2(SO4)3) = 0.01354 mol Al+3 ions Therefore, the total number of Al+3 ions in solution is the sum: 0.01354 + 0.0120 = 0.02554 mol Al+3 ions The last piece of information needed to determine the concentration of the final solution is the volume of the final solution. Since the two volumes were mixed, the volume of the final solution will be the sum of the two solutions. 0.0431 L + 0.0146 L = 0.0577 L Therefore, to calculate molarity: Molarity = moles of solute / liters of solution Molarity = 0.02554 mol / 0.0577 L = 0.443 M Al+3

- Q: Can the aluminum sheets be used for packaging applications?

- Yes, aluminum sheets can be used for packaging applications. Aluminum is a versatile material that offers several benefits for packaging. It is lightweight, yet strong and durable, making it ideal for protecting and preserving various products, including food, beverages, pharmaceuticals, and cosmetics. Aluminum sheets can be easily formed into different shapes and sizes, allowing for customized packaging solutions. Additionally, aluminum has excellent barrier properties, providing a protective barrier against moisture, oxygen, light, and other contaminants, which helps to extend the shelf life of the packaged products. The material is also recyclable, making it an environmentally friendly choice for packaging applications. Overall, aluminum sheets are widely used in the packaging industry due to their versatility, strength, durability, barrier properties, and recyclability.

- Q: 1) Aluminum ore is not formed in Quebec (why not?) 2)but aluminum ore is smelted into aluminum in Quebec. Why?

- The okorder

Send your message to us

Aluminum Sheets in Tennessee - DC/CC China Cheap Price 1060 1100 O Aluminum Disc for Turkey Barrels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords