Sublimation Aluminum Sheets - Aluminum 1100 1050 3003 Deep Drawing Hot Sale China Cheap Price Aluminum Disc for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

1100-H14-DIAMOND EMBOSSED ALUMINUM SHEET

Thickness:1.2mm---4mm,

width:1000mm---1500mm

Product code: 618 a - 33 y titanium matte aluminum plate

Technical parameters

Aluminum alloy/material: 1100

Tensile strength N/was: 115-125

The yield strength of N/was: 150-150

Elongation % : 3 or more

Rainbow degrees: no

Process: light oxidation process

Product description: surface "colored metal silken face" as the main characteristics of the product, completely metal texture, color variety, products can be mild tensile and bending.

Product use: can be used to directly shape stamping, screen printing, thermal transfer two composite process, etc.Used in architectural decoration, household appliances, switch panel, auto parts, lamps lighting, electronic hardware and other industries.

Supply scope of coil or sheet

Mm thickness specification: 0.4 1

Maximum width mm: 1250

The tolerance range

Mm thickness: 0.02 mm

The width of the mm: 2 -

Mm length: 2 -

Actual weight kg: plus or minus 2

Protective film

Protective film on the surface of the aluminum quality assurance period for six months, aluminum is kept dry and ventilated, avoid heat and direct sunlight.If the aluminium material stored in high temperature or direct sunlight can cause protective film, or unable to tear in addition to wait for a phenomenon.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

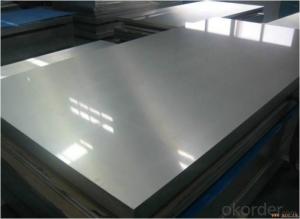

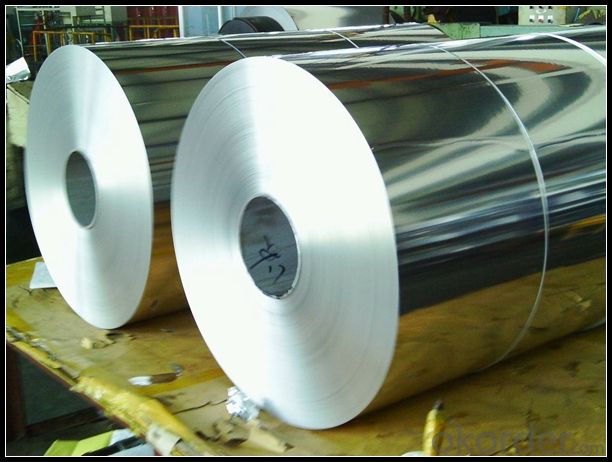

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7 What is Aluminum?

Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials. The most useful compounds of aluminium, at least on a weight basis, are the oxides and sulfates.

- Q: Can aluminum sheets be used for window frames?

- Indeed, window frames can be made using aluminum sheets. The utilization of aluminum for window frames is widespread because of its durability, lightweight characteristics, and ability to resist corrosion. Aluminum frames provide exceptional strength and stability and can be effortlessly tailored to suit any window size or shape. Moreover, aluminum frames necessitate minimal upkeep and can be painted or anodized to match any preferred color or finish. In summary, aluminum sheets serve as a versatile and dependable material for the construction of window frames.

- Q: What are the different methods of joining aluminum sheets without welding?

- There are several methods of joining aluminum sheets without welding, including adhesive bonding, mechanical fastening (such as screws or rivets), clinching, and using non-welding techniques like friction stir welding or laser welding.

- Q: What is the fire rating of 101 aluminum sheets?

- The fire rating of 101 aluminum sheets is typically dependent on the particular alloy and thickness of the sheets. Due to its low melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum has the potential to deform or melt when exposed to intense heat. Nevertheless, it is important to highlight that aluminum is not flammable and does not aid in the propagation of fire. Fire resistance can be improved by applying fire-resistant coatings or by incorporating it with other fire-resistant substances. In conclusion, it is crucial to seek advice from manufacturers or industry professionals to ascertain the fire rating of specific 101 aluminum sheets.

- Q: Can aluminum sheets be bent without breaking?

- Yes, aluminum sheets can be bent without breaking. Aluminum is a highly malleable and ductile metal, which means it can be easily shaped and bent without fracturing or cracking. This property makes aluminum an ideal material for various applications, including the manufacturing of aircraft, automobiles, and household items. The flexibility of aluminum sheets allows for the creation of intricate designs and complex shapes, making it a highly versatile material. However, it is important to note that the thickness and grade of the aluminum sheet can influence its bendability. Thicker sheets may require more force and specialized tools to achieve the desired bend, while softer grades of aluminum may be more easily bent.

- Q: What is the tensile strength of 101 aluminum sheets?

- The tensile strength of 101 aluminum sheets varies depending on the thickness and manufacturing process, but it typically ranges from 20,000 to 30,000 pounds per square inch (PSI).

- Q: Can aluminum sheets be reused or recycled after their initial use?

- <p>Yes, aluminum sheets can be recycled again after use. Aluminum is one of the most recycled materials globally due to its low cost of recycling and its ability to retain its properties even after multiple recycling processes. Recycling aluminum saves energy compared to producing new aluminum from raw materials, and it helps reduce waste in landfills.</p>

- Q: How to clean the engine oil and kerosene on the surface of aluminum sheet?

- you can buy a bottle of petroleum ether in chemical raw material shop, it will be clean after rubbing, or you can buy solvent oil.

- Q: What types of aluminum sheets are recommended for use in cold climates?

- <p>Yes, there are specific types of aluminum sheets suitable for cold climates. These include 3003-H14 and 5052-H32 aluminum sheets. 3003-H14 is known for its excellent corrosion resistance and formability, making it ideal for cold weather applications. 5052-H32 offers high strength and good corrosion resistance, which is beneficial in extreme cold conditions. Both types can withstand low temperatures without significant loss of strength or ductility, ensuring reliability and durability in cold environments.</p>

- Q: What are the common surface treatments for aluminum sheets used in outdoor applications?

- The common surface treatments for aluminum sheets used in outdoor applications include anodizing, powder coating, and PVDF coating. Anodizing is an electrochemical process that creates a durable, corrosion-resistant layer on the surface of the aluminum sheet. It involves immersing the sheet in an electrolyte solution and applying a current to form a thick oxide layer. Anodized aluminum sheets are highly resistant to weathering, UV rays, and corrosion, making them suitable for outdoor applications. Powder coating is a dry finishing process where a powdered paint is electrostatically applied to the aluminum sheet. The sheet is then heated, causing the powder to melt and form a smooth, durable coating. Powder coating offers excellent resistance to weathering, scratches, and fading, making it ideal for outdoor use. Additionally, it provides a wide range of color options and a uniform, attractive appearance. PVDF (polyvinylidene fluoride) coating is a high-performance coating that combines resin with ceramic particles. This coating is applied as a liquid and then cured at high temperatures to form a continuous, protective film on the aluminum sheet. PVDF coatings provide exceptional resistance to fading, chalking, and chemical exposure, making them suitable for harsh outdoor environments. They also offer excellent color retention, durability, and resistance to UV rays. All these surface treatments enhance the durability, weather resistance, and aesthetic appeal of aluminum sheets, making them ideal for outdoor applications such as architectural facades, signage, transportation, and marine industries. It is important to select the appropriate surface treatment based on the specific requirements of the outdoor application, considering factors such as durability, color options, and resistance to weathering and corrosion.

- Q: Can aluminum sheets be etched or engraved?

- Indeed, it is possible to etch or engrave aluminum sheets. The process entails removing a portion of the material from the surface by utilizing acid or a laser with substantial power. This technique allows for the creation of detailed designs, patterns, or even textual elements on the aluminum sheet. The applications for etching or engraving are diverse, including signage, decorative items, and industrial components. To achieve the desired appearance, color or other finishes can be added to further enhance the resulting design on the aluminum sheet.

Send your message to us

Sublimation Aluminum Sheets - Aluminum 1100 1050 3003 Deep Drawing Hot Sale China Cheap Price Aluminum Disc for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords