Damascus Steel Billet for Producing Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Damascus Steel Billet for Producing Building Material

Specification of Damascus Steel Billet

Grade: mild steel 3sp 4sp 5sp

Dimensions: 100mmx100mm

Standard: AISI, ASTM, BS, DIN, GB, JIS, steel billet

teel billet length:: 3m-12m

billet steel grade:: 3sp 4sp 5sp q235 q195 q255 q275 20mnsi

Main Features of Damascus Steel Billet

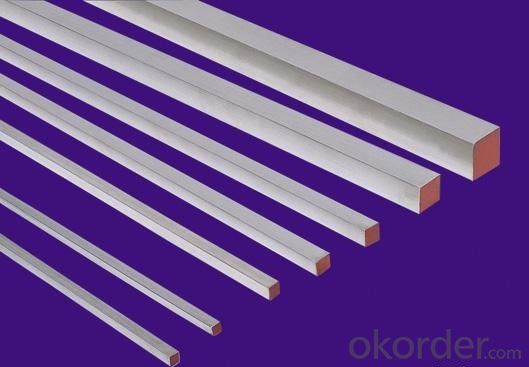

| Type : | Square steel billet |

| Steel Grade: | 3sp 5sp q195 q235 q255 q275 20mnsi ,astm a615 gr.60 |

| Size: | 60x60mm-150x150mm |

| Length: | 2m-12m . |

| Processing: | Hot rolled continous cast. |

| Application: | Wire rod , rod , deformed bars , profile steel , mechine parts , and steel mould ect . |

| Packing: | Loose Packing. |

| MOQ: | 1000Tons |

| Delivery Time: | 25days |

| Payment: | T/T , L/C,West Union , Cash . |

| Trade term: | FOB, CFR, CIF ,EXW. |

| Trans term: | FIO ,FILO ,FLT. |

Datas for Damascus Steel Billet

Steel billet Steel Grade C(%) Mn(%) Si(%) P(%) S(%) Q235 ≤0.20 ≤1.40 ≤0.35 ≤0.045 ≤0.045 Q275 ≤0.22 ≤1.50 ≤0.35 ≤0.045 ≤0.045 20MnSi 0.17-0.25 1.20-1.60 0.40-0.80 ≤0.050 ≤0.050 3SP 0.18-0.22 0.60-0.85 0.05-0.30 ≤ 0.040 ≤0.050 5SP 0.28-0.37 0.80-1.00 0.15-0.30 ≤ 0.040 ≤0.050

FAQ

Q:Why should choose us?

A:Stable quality ----continous casting hot rolled production techenic, strictly quality control system.

Lower price -------Not the cheapest but the lowest price at the same quality .

Good service -----Satisfactory service within 24hours.

Delivery time ------15-25days for the mass production .

Discount---------------discount base on monthly large quantity purchase in long term.

Pictures:

- Q: What are the safety regulations for working with steel pipes?

- The safety regulations for working with steel pipes may vary depending on the specific circumstances and location, but some common safety measures include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots, ensuring proper handling techniques to prevent injuries, using proper lifting equipment to prevent strain or back injuries, implementing proper ventilation and respiratory protection when working in confined or poorly ventilated spaces, and following proper procedures for welding, cutting, or bending steel pipes to minimize the risk of fire or explosions. It is essential to consult and adhere to local safety regulations and guidelines to ensure a safe working environment when dealing with steel pipes.

- Q: What is the difference between hot-rolled and cold-rolled steel pipes?

- The main difference between hot-rolled and cold-rolled steel pipes lies in the manufacturing process. Hot-rolled steel pipes are produced at high temperatures, which results in a rougher surface and less precise dimensions. On the other hand, cold-rolled steel pipes are manufactured at lower temperatures, leading to a smoother surface finish and more accurate measurements. Additionally, the hot-rolling process allows for a wider range of steel grades and sizes, while cold-rolled pipes are generally limited in terms of thickness and diameter.

- Q: What are the factors to consider when selecting pipe materials for high-temperature applications?

- When selecting pipe materials for high-temperature applications, there are several factors that need to be taken into consideration. Firstly, the material's thermal conductivity is crucial. High-temperature applications require materials with high thermal conductivity to ensure efficient heat transfer and prevent heat buildup. Materials such as copper and stainless steel have excellent thermal conductivity and are commonly used in high-temperature pipe installations. Secondly, the material's resistance to thermal expansion is important. When exposed to high temperatures, pipes tend to expand. Therefore, it is crucial to choose materials with low thermal expansion coefficients to prevent deformation and potential pipe failure. Materials like carbon steel and stainless steel exhibit relatively low thermal expansion and are suitable for high-temperature applications. Thirdly, the material's mechanical strength and resistance to corrosion need to be considered. High temperatures can cause certain materials to weaken or corrode, leading to structural failures. It is essential to select materials that can withstand high temperatures without compromising their mechanical strength or corroding easily. Materials like alloy steel and nickel-based alloys are known for their high strength and resistance to corrosion, making them suitable for high-temperature applications. Furthermore, the material's cost and availability should be taken into account. Some high-temperature pipe materials may be expensive or difficult to obtain, which can impact the overall project budget and timeline. It is essential to balance the desired material properties with the project's financial and logistical constraints. Lastly, the specific application requirements and industry standards should be considered. Different industries may have specific guidelines or regulations regarding pipe materials for high-temperature applications. It is crucial to ensure that the selected materials comply with these standards to ensure safety, reliability, and compliance with industry regulations. In conclusion, the factors to consider when selecting pipe materials for high-temperature applications include thermal conductivity, resistance to thermal expansion, mechanical strength, resistance to corrosion, cost and availability, and compliance with industry standards. By carefully evaluating these factors, one can choose the most suitable pipe material to ensure efficient and reliable operation in high-temperature environments.

- Q: What are the standard specifications for steel pipes?

- The standard specifications for steel pipes vary depending on the intended use and industry requirements. However, some common standard specifications include the pipe's size, wall thickness, material composition (such as carbon steel or stainless steel), and pressure ratings. Other specifications may include the pipe's shape, length, and surface finish. It is essential to consult relevant standards organizations, such as ASTM or ASME, to determine the specific standard specifications for steel pipes in a given application.

- Q: What are the common standards for coating and lining of steel pipes?

- Various organizations and regulatory bodies have outlined the common standards for coating and lining steel pipes to ensure their durability, corrosion resistance, and overall quality. These standards are widely recognized and utilized in different industries. Here are some examples: 1. The American Society for Testing and Materials (ASTM) has developed numerous standards for coating and lining steel pipes. For instance, ASTM A775/A775M addresses epoxy-coated reinforcing steel, ASTM A1064/A1064M focuses on metallic-coated steel wire, and ASTM A1057/A1057M covers fusion-bonded epoxy-coated steel reinforcement. 2. The American Water Works Association (AWWA) has established standards specifically for coating and lining steel pipes used in the water industry. AWWA C210 deals with liquid epoxy coating systems for both the interior and exterior of steel water pipelines, while AWWA C213 focuses on fusion-bonded epoxy coating for these pipelines. 3. The National Association of Corrosion Engineers (NACE) develops standards and recommended practices for corrosion control in steel pipes. NACE SP0169 provides guidelines for selecting and applying coatings for underground or submerged steel pipelines, and NACE SP0198 offers recommendations for external coatings of steel pipelines. 4. The International Organization for Standardization (ISO) has also developed various standards pertaining to coating and lining steel pipes. ISO 21809-1 specifies the requirements for external coatings applied to buried or submerged pipelines, while ISO 21809-2 concentrates on the internal coating and lining of such pipelines. These standards encompass multiple aspects of the coating and lining process, including surface preparation, application methods, minimum coating thickness, adhesion, and quality control. Adhering to these standards ensures that steel pipes receive proper protection against corrosion, abrasion, and other forms of deterioration. Consequently, they enjoy a longer service life and enhanced performance in industries such as oil and gas, water supply, and infrastructure.

- Q: Can steel pipes be used for firefighting systems?

- Yes, steel pipes can be used for firefighting systems. Steel pipes are commonly used for their durability, strength, and resistance to high pressure and heat. They can effectively transport water or other fire suppressants to extinguish fires efficiently, making them a reliable choice for firefighting systems.

- Q: How are steel pipes used in the construction of stadiums and arenas?

- Steel pipes are commonly used in the construction of stadiums and arenas for various purposes. They are primarily used for structural support, providing a sturdy framework for the buildings. Steel pipes are also used in the installation of plumbing systems, helping to transport water and other fluids throughout the facility. Additionally, steel pipes are utilized for the construction of ventilation and HVAC systems, ensuring proper air circulation and temperature control within the stadiums and arenas.

- Q: What is the role of steel pipes in the transportation of petroleum products?

- Steel pipes have a crucial function in the transportation of petroleum products, as they are specifically designed to endure the high pressure and extreme temperatures associated with oil and gas transportation. A primary responsibility of steel pipes in this process is to serve as a dependable and secure conduit for transporting petroleum products over long distances. They are utilized to construct pipelines that span hundreds or even thousands of miles, connecting oil fields, refineries, and distribution centers. Steel pipes are the preferred choice for this purpose because of their strength, durability, and resistance to corrosion. The high tensile strength of steel allows these pipes to withstand the immense pressure exerted by petroleum products as they flow through the pipelines. Additionally, steel pipes can endure extreme temperatures, ensuring the safe transportation of hot crude oil or refined petroleum products. Moreover, steel pipes possess a high resistance to corrosion, which is of utmost importance given the corrosive nature of petroleum products. To further enhance their corrosion resistance, the pipes are often coated with protective materials such as epoxy or polyethylene. This coating helps prevent leaks or ruptures that could cause environmental damage or safety hazards. Steel pipes also offer cost-effective and efficient transportation of petroleum products. They have a smooth interior surface, which reduces friction and allows for a more efficient flow of oil or gas. This, in turn, helps minimize energy consumption and maximize the throughput of the pipeline system. In conclusion, the main role of steel pipes in the transportation of petroleum products is to provide a reliable, secure, and efficient means of transporting oil and gas over long distances. They are designed to withstand high pressure, extreme temperatures, and corrosion, ensuring the safe and efficient delivery of petroleum products from production sites to refineries and distribution centers.

- Q: What is the difference between steel pipes and cast iron soil pipes?

- Steel pipes and cast iron soil pipes differ in their composition and characteristics. Steel pipes are made of an alloy of iron and carbon, providing them with high strength and durability. They are commonly used for transporting fluids and gases, and are resistant to corrosion. On the other hand, cast iron soil pipes are made from molten iron that is poured into molds. They are primarily used for drainage and sewage systems due to their excellent soundproofing properties. Cast iron soil pipes are more resistant to fire and have a longer lifespan compared to steel pipes. Additionally, cast iron soil pipes are typically heavier and thicker than steel pipes, making them more suitable for underground installations. However, steel pipes are lighter and easier to handle, making them a preferred choice for above-ground applications. Ultimately, the choice between steel pipes and cast iron soil pipes depends on the specific requirements of the project, such as the intended use, location, and budget.

- Q: How are steel pipes used in the manufacturing of desalination plants?

- Steel pipes are used in the manufacturing of desalination plants to transport the seawater from the intake point to the treatment facilities. These pipes are durable, corrosion-resistant, and can withstand the high-pressure conditions required for the desalination process.

Send your message to us

Damascus Steel Billet for Producing Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords