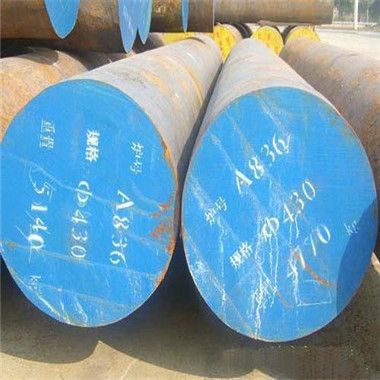

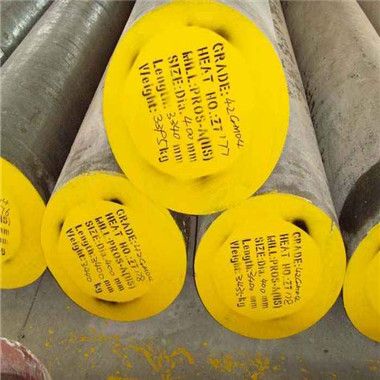

D6 Cold Work Mould Steel Round Bars DIN1.2436

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

D6 Cold Work Mould Steel Round Bars DIN1.2436

AISI D6 tool steel is a high-carbon, high chromium tool steel alloyed with tungsten that is characterized by high compressive strength, high wear resistance, high surface hardness and good hardening stability

Specification of D6 tool steel

1.Diameter:60mm~600mm

2.Length:1-6.5m or as customer's request

The chemical composition of D6 tool steels is outlined in the following table.

| Element | Content (%) |

|---|---|

| Iron, Fe | 83.05 |

| Chromium, Cr | 12.5 |

| Carbon, C | 2.05 |

| Tungsten, W | 1.3 |

| Manganese, Mn | 0.8 |

| Silicon, Si | 0.3 |

Forging

D6 tool steel is heated slowly and uniformly to 700°C (1292°F) and then more rapidly to 900-1050°C (1652-1922°F).

Annealing

D6 tool steel is then annealed at 800-840°C (1472-1544°F) and cooled. Hardness of the steel after annealing will be approximately 225 Brinell.

Stress Relieving

Stresses from D6 tool steel can be eliminated before hardening by heating up to 650-700°C (1202-1292°F), if machining operations have been heavy. The steel is then allowed to cool slowly.

Hardening

D6 steel is pre-heated slowly to 750-800°C (1382-1472°F) and thoroughly soaked. Heating is then continued till the final hardening of 950-980°C (1742-1796°F), followed by air or oil quenching.

Tempering

The steel is heated uniformly and thoroughly at the selected tempering temperature. Double tempering can also be carried out with intermediate cooling to room temperature.

Main applications of D6 tool steels:

Forming tools

Molds for abrasive plastics and ceramics

Long-run press tools

Blanking and shearing tools for hard materials.

- Q: How do steel round bars perform in high-pressure applications?

- Steel round bars perform well in high-pressure applications due to their high tensile strength and excellent resistance to deformation. They are able to withstand the extreme forces and pressures without compromising their structural integrity. Additionally, steel round bars also exhibit good corrosion resistance, making them suitable for various high-pressure environments, such as hydraulic systems, pressure vessels, and pipelines.

- Q: Can steel round bars be used in the production of shafts?

- Yes, steel round bars can be used in the production of shafts. Steel round bars are commonly used in shaft manufacturing due to their high strength, durability, and ability to withstand heavy loads and torsional forces. They can be machined and shaped into the desired dimensions and specifications required for shafts in various industries such as automotive, aerospace, machinery, and construction.

- Q: Can steel round bars be machined using CNC equipment?

- Yes, steel round bars can be machined using CNC equipment. CNC (Computer Numerical Control) machines are capable of accurately and precisely shaping steel round bars into various desired forms and dimensions.

- Q: How do steel round bars compare to glass round bars?

- Steel round bars and glass round bars differ in terms of their properties and applications. Here's a comparison: Strength and Durability: Steel round bars possess exceptional strength and durability, with a high tensile strength that allows them to withstand heavy loads and pressure without deformation. Conversely, glass round bars are fragile and easily break under stress or impact, making them unsuitable for structural applications where strength is crucial. Weight: Steel round bars are considerably heavier than glass round bars. Although this can be advantageous in applications requiring stability and support, it can be a disadvantage in situations where lightweight materials are desired. Corrosion Resistance: Steel round bars are susceptible to corrosion when exposed to moisture or harsh environments. However, they can be safeguarded by coatings or alloys that enhance their resistance to corrosion. In contrast, glass round bars are not prone to corrosion, making them an ideal choice in corrosive environments. Transparency and Aesthetics: Glass round bars have the advantage of transparency, making them suitable for decorative purposes or applications where visibility is important. On the other hand, steel round bars are opaque and lack this characteristic. Thermal Conductivity: Steel round bars have higher thermal conductivity compared to glass round bars. This property makes them more suitable for applications requiring heat transfer or dissipation. Cost: Steel round bars are generally more affordable than glass round bars. The production processes and limited availability of specialized glass types contribute to the higher cost of glass round bars. In conclusion, steel round bars are favored for their strength, durability, and cost-effectiveness, making them suitable for structural applications. Conversely, glass round bars offer transparency, aesthetic appeal, and corrosion resistance, making them suitable for decorative or specific applications where visibility is important. Ultimately, the choice between the two materials depends on the specific requirements and constraints of the project at hand.

- Q: How do you measure the straightness tolerance of a steel round bar?

- To determine the straightness tolerance of a steel round bar, various methods can be employed based on the desired level of accuracy and precision. Below are several commonly used techniques: 1. Visual Inspection: This straightforward approach involves visually examining the bar for any noticeable deviations from straightness. Placing the bar on a flat surface allows for the detection of bends or curves along its length. However, it is worth noting that this method is subjective and may not yield precise measurements. 2. Straightedge Method: Using a straightedge such as a ruler or precision straightedge, one can assess the presence of gaps or spaces between the straightedge and the bar's surface. This method offers a higher level of accuracy but can still be influenced by human error. 3. Dial Indicator Method: By utilizing a dial indicator, a precise measuring tool, the straightness tolerance can be measured. Fixing the dial indicator to a stationary point and moving it along the length of the bar enables the identification of any deviations from a straight line. This method provides more precise measurements and can quantify the straightness tolerance in specific units like inches or millimeters. 4. Laser Measurement: Laser systems, such as laser alignment devices, serve as an effective means of measuring the straightness tolerance of a steel round bar. These systems project a straight line onto the bar's surface using lasers and then analyze any deviations from this line. Laser measurement offers highly accurate and repeatable results, making it suitable for applications requiring strict tolerances. It is essential to consider the required level of accuracy, the size of the round bar, and the available resources and equipment when selecting a measurement method. It is also advisable to consult industry standards and guidelines to ensure compliance with specific tolerances and requirements relevant to your application.

- Q: What is the difference between a smooth and a precision ground steel round bar?

- A smooth steel round bar refers to a steel rod that has a plain surface without any specific surface treatment or finishing process. It is typically produced through hot rolling or cold drawing methods, resulting in a basic cylindrical shape with a relatively rough surface texture. Smooth steel round bars are commonly used in various applications where a smooth exterior finish is not a critical requirement. On the other hand, a precision ground steel round bar undergoes an additional manufacturing process to achieve a more precise and refined surface finish. The precision grinding process involves removing any imperfections or irregularities from the surface of the steel rod, resulting in a highly smooth and polished finish. This process ensures that the diameter of the round bar remains consistent along its length and that the surface has a superior level of finish and accuracy. Precision ground steel round bars are widely used in applications that demand tight tolerances, precision machining, or where a smooth and polished surface is essential. Industries such as aerospace, automotive, tooling, and manufacturing often rely on precision ground steel round bars for their high-quality surface finish, dimensional accuracy, and reliable performance. In summary, the main difference between a smooth and a precision ground steel round bar lies in the surface finish and level of precision achieved. While a smooth steel round bar has a basic, rough surface texture and is suitable for general applications, a precision ground steel round bar undergoes additional grinding processes to achieve a highly smooth, polished, and accurate surface finish, making it ideal for applications requiring tight tolerances and precision machining.

- Q: What are the advantages of using non-alloy steel round bars?

- There are several advantages of using non-alloy steel round bars. Firstly, non-alloy steel round bars are known for their high strength and durability. They have a higher tensile strength compared to alloy steel, making them suitable for various applications where strength is a crucial requirement. This makes them ideal for use in industries such as construction, automotive, and manufacturing. Additionally, non-alloy steel round bars have excellent weldability and machinability. They can be easily welded and formed into various shapes, allowing for flexibility in design and fabrication. This makes them convenient to work with and saves time and effort during the manufacturing process. Non-alloy steel round bars also have good corrosion resistance properties. They are less prone to rust and degradation, making them suitable for use in environments where exposure to moisture or corrosive substances is a concern. This corrosion resistance ensures the longevity and reliability of the steel bars, reducing maintenance and replacement costs in the long run. Furthermore, non-alloy steel round bars are cost-effective compared to alloy steel. They are more affordable and readily available, making them a cost-efficient choice for a wide range of applications. This affordability makes non-alloy steel round bars a popular choice for small-scale projects or businesses with budget constraints. Overall, the advantages of using non-alloy steel round bars include high strength, excellent weldability and machinability, good corrosion resistance, and cost-effectiveness. These qualities make them a versatile and reliable option for various industries and applications.

- Q: Can steel round bars be used for making springs?

- Yes, steel round bars can be used for making springs. Steel is a widely used material for springs due to its high strength and durability. Steel round bars can be shaped into various types of springs, including compression springs, extension springs, and torsion springs. The round bar can be cut to the desired length and then heat-treated to achieve the desired hardness and springiness. The specific type of steel and the heat treatment process will determine the spring's characteristics, such as its load-bearing capacity, flexibility, and resistance to fatigue. However, it is important to note that the design and engineering of springs require careful consideration of factors such as the required spring rate, maximum load, and operating conditions to ensure the optimal performance of the spring.

- Q: What is the maximum temperature a steel round bar can withstand?

- The maximum temperature a steel round bar can withstand depends on several factors such as the specific type of steel, its composition, and the intended application. Generally, most common grades of steel have a maximum temperature limit of around 1,200 to 1,400 degrees Fahrenheit (650 to 760 degrees Celsius). However, some stainless steels can withstand higher temperatures, reaching up to 2,200 degrees Fahrenheit (1,200 degrees Celsius). Additionally, specialized heat-resistant alloys such as Inconel or Hastelloy can withstand even higher temperatures, up to 2,500 degrees Fahrenheit (1,370 degrees Celsius) or more. It is crucial to consult the manufacturer's specifications or conduct thorough research to determine the precise maximum temperature limit for a specific steel round bar in order to ensure its safe and efficient use.

- Q: How are steel round bars used in the construction of airports and runways?

- Steel round bars are commonly used in the construction of airports and runways for various purposes. They are primarily used to reinforce the concrete structures, such as the foundation, columns, beams, and slabs. The round bars provide strength and durability to the concrete, ensuring that it can withstand heavy loads and resist cracking or collapsing. Additionally, steel round bars are also used in the construction of drainage systems, fencing, and other infrastructure components within airports and runways.

Send your message to us

D6 Cold Work Mould Steel Round Bars DIN1.2436

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords