CYZ Type self priming centrifugal EX-Proof motor Oil pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction

Products Introduction

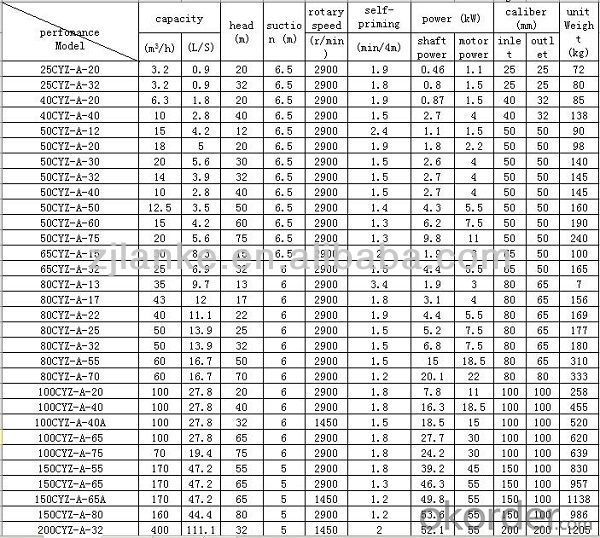

Main datas:

Capacity( flow rate) : 3.2-550 m3/h

Head : 12-80 m

Speed: 1450 / 2900 rpm

Power: 0.75 ~ 132 hp

Suction:4-5.5 m

Advantage :

1. Big pump body pass 60% of the inlet&outler solid ,

2. High suction head 4-5.5 m,have sewage

3. Used for oil and Marine, Copper impeller

4. OEM ,L/C ,TT ,O/A ,D/P,D/A and so on

5.CE ,TUV .ISO .CO

Name: Lanco brand CYZ-A self priming Centrifugal Electric oil pump 24 volt

Summarize

CYZ-A series fuel pump is a new modified centrifugal pump which is

developed on the basis of absorbing domestic and overseas advanced technology of the same

product and combining many years design and manufacturing experience of our company.

1) Detailed instructions

Lanco brand cyz Series Siemens Electric Oil Pump

1.Flow capacity:3.2-500m3/h

2.Head: 12-80m Ciemens oil pump

3.Rotary speed: 2900rmp

4.Power: 0.75-110kw

5.Suction lift: 5-6.5m

2). Application Area

1. fuel pump is widely used totransport gasoline,kerosene,diesel oil ,oil for warehouse ,oil station ,oil tanker,dock,tank truck,airdrome ect.

2.Used in chemical industry ,pharmaceutics, brew-age,electroplate ,printing and dyeing,papermaking, electric power ,mine etc.

3. Suitable for Marine cargo pump, bilge pump, fire pump, ballast pump nd cooling water circulation machine

4. Applicable to the oil industry, oil depot, oil tank truck land .

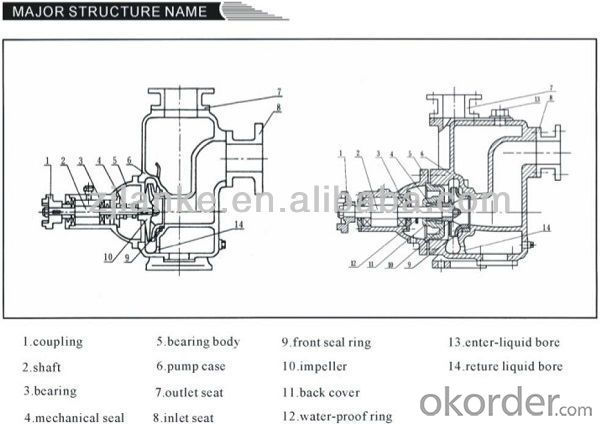

3) Oil pump characteristic 1.Simple structure,convenient operation and maintenance,stable working,hagh efficiency,

long life,good self-priming etc are its main characteristic.

2.It can also be used as pump for cleaning off cabin in tanker and water supply of ship with

high efficiency.

3.It's made up of material of high quality.Seal is hard alloy mechanical seal.So the pumps

have a long life.

4.It need not security valve in output pipeline and no bottom valve in suction valve

insuction pipeline,so it perdigests pipeline system and improves working condition.

4) Operating Condition

1.Medium temperature:-20°C~80°C,

2.Viscidity≤100centipoise

3.Particals consistency can reach 30%.

5) Mounting Configuration

| ♦ Frame Mounted |

| ♦ Base Mounted Electric Driven |

| ♦ Engine Driven SAE Mounted |

| ♦ Engine Driven Skid or Trailer Packages |

| ♦ Horizontal or Vertical V-Belt Driven |

5)Parameter

Samply available: 7~10days.

Qty: 1pc, only pump head is provided.

Price: US$100~200

OEM is welcome

OEM expierence: more than 10 years.

Countries: Germany, U.S.A, Spain, Italy, United Kingdom etc

Warranty: the whole pump is guaranteed within 1 year, the pump's spare parts are guranteed for 3 months from the date of delivery.

For more information, please do not hesitate to contact me.

The information should be including inquiry as following:

1.Pump's flow rate

2.Pump's Head (Pressure

3.Driven Mode: By electric motor or diesel engine or bare shaft etc

4.Power and rotary speed

5.Suction lift for self priming pump

6.Temperature of liquid if you can provide

Upon the receipt of the pump's parameter, we can send our quotation to you within 24 hours.

Or the condition of pump station would be provided.

♦FAQ:

1. Q: Can I know more about your products?

A: Pls view our website: www.lanco.cc.

2. Q: What’s your MAQ of this item?

A: 1~2PCS

3. Q: What is the lead time?

A: 10~30 days after receiving your payment,depends on pumps.

4. Q: where is your loading port?

A: Ningbo, China port

5. Q: Are you a manufacturer or trading company

A: We are a manufacturer specialize in water pump and other pumps more than 20 years.

For more information, please contact me.

- Q: What is the dry running protector of screw pump? What's the principle and function? Thank you

- The utility model relates to a screw pump dry running protector, which is used for protecting the stator and the rotor of the screw pump from being transported by air

- Q: What is the Rhodes pump?

- The ultimate vacuum of roots pump depends on the pump structure and manufacturing accuracy, and also depends on the limit vacuum of the front pump. In order to increase the limit vacuum of the pump, the roots pump can be used in series. The working principle of roots pump is similar to roots blower. As the rotor continues to rotate, the gas is pumped from the intake air to the space between the rotor and the pump housing V0, and then discharged through the exhaust port. Since the V0 space is fully enclosed after inhalation, the gas in the pump cavity does not compress and expand. But when the top of the rotor turns off the edge of the exhaust and the V0 space communicates with the exhaust side, the gas pressure at the exhaust side is higher, and a part of the gas flows back into the space V0, causing a sudden increase in the gas pressure. As the rotor continues to rotate, the gas is expelled from the pump. Roots pump in the pump cavity, there are two "8" shape of the rotor perpendicular to each other on a pair of parallel axis, by a transmission ratio of 1 of a pair of gear belt movements synchronous reverse movement of each other. In the rotor, the rotor and the pump housing between the wall to maintain a certain gap, you can achieve high speed operation.

- Q: How to select metering pump head?

- The manufacturers of chemicals will give relevant recommendations, or consult the ProMinent chemical corrosion chart to determine the compatibility of the chemicals with the contact material.

- Q: Shielding pump is the main drawback of electricity? How much does it cost more than an ordinary centrifugal pump? Is there any noise in the running of the canned pump? How much is it lower than the noise of the common centrifugal pump?

- The graphite bearing lubrication medium, make the operation less noise and manual, reduce maintenance costs; in recent years, bearing material added with silicon carbide SIC, super hard, life is better than that of graphite bearing.The vertical structure can be installed on the pipeline like a valve, the installation is convenient and quick, and the motor and the impeller can be drawn out only when the utility model is used, and the pipeline is not needed to be removed.The utility model can be installed and run with a shock absorber or a damping pad, so that the pump is less noisy at running time.

- Q: What is a positive displacement pump? He Weizheng displacement?

- Includes a pump housing (10), a pump chamber (24), the pump chamber has an entrance channel (21) and an outlet check valve (17) export control channel (28), a displacement member (13), the definition of the pump cavity in a direction of movement in (24) and in a stroke section in the pump cavity (S) in reciprocating motion

- Q: Why does the centrifugal pump start and close first when the outlet valve is closed?

- The contact is burned out, the bond and so on the accident, therefore closes the outlet valve, starts the electric machinery, at this time the electric machinery belongs to the no-load current movement, greatly reduces the big current impact

- Q: Is vane pump good or gear pump good?

- 1) the reversible design of gear pumps can also usually reverse, but reverse after the suction port change, and the pump safety valve does not work; leaf pump is generally not allowed to reverse. 3) the single acting vane pump can be designed to change the eccentric distance by moving the stator at the constant speed, so as to achieve the purpose of variable direction.

- Q: The working principle of magnetic pump

- Control of cooling fluid flowThe pump is running, you must use a small amount of liquid in the magnetic separation between the rotor and the casing annulus area and sliding friction bearings for flushing cooling. The cooling liquid flow pump design flow is usually 2%-3%, the annular area between the magnetic rotor and sleeve of eddy current generated because of high heat. When the cooling and lubrication the liquid is not enough or poor flushing holes to plug, will result in permanent magnet medium temperature is higher than the operating temperature of the inner magnetic rotor gradually loses magnetism, the magnetic actuator failure. When the medium is water or water-based liquid, can make the annulus area temperature maintained at 3-5 DEG C; when the medium or hydrocarbon oil that can make the annulus area temperature maintained at 5-8 degrees.

- Q: Why does the centrifugal pump start with a closed valve and the axial pump starts with an opening valve?

- The power of axial flow pump decreases with the increase of flow rate, and it is a steep curve, so the centrifugal pump starts with an open valve.

- Q: What is the difference between an air pump and a water pump?

- A pump is a machine that transports liquids or pumps liquids. It will be the prime mover of the mechanical energy or other external energy transfer to the liquid, the liquid energy increase, mainly used to transport liquids including water, oil, alkali liquid, emulsion, suspension emulsion and liquid metal, but also transport liquid, gas mixtures and liquids containing suspended solids.

Send your message to us

CYZ Type self priming centrifugal EX-Proof motor Oil pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords