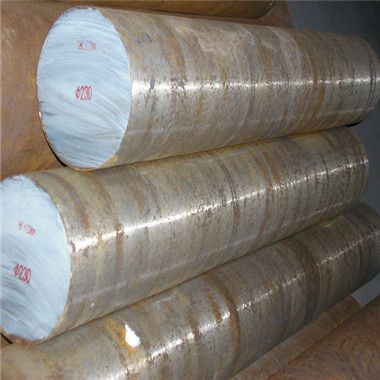

Cr12 Steel Round Bars D3 Galvanized Round Bars Din1.2080 Tool Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,JIS,GB,BS,DIN,API,EN,ASTM

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,CE

Thickness:

as required

Length:

as required

Net Weight:

as required

| Cr12 Steel Round Bars D3 Galvanized Round Bars Din1.2080 Tool Steel | |||||||||||

| Comparative standard | Grade | C | Si | Mn | Cr | Mo | V | W | P | S | Ni |

| GB | Cr12 | 2.00-2.30 | ≤0.40 | ≤0.40 | 11.5-13.0 | - | - | - | ≤0.030 | ≤0.030 | - |

| AISI | D3 | 3.00-2.35 | 0.10-0.60 | 0.20-0.60 | 11.0-13.5 | - | ≤1.00 | ≤1.00 | ≤0.030 | ≤0.030 | - |

| W-Nr. | 1.2080 | 1.90-2.20 | 0.10-0.60 | 0.20-0.60 | 11.0-13.0 | - | - | - | ≤0.030 | ≤0.030 | - |

| DIN | X210Cr12 | ||||||||||

| BS | BD3 | 1.90-2.30 | ≤0.60 | ≤0.60 | 12.0-13.0 | - | ≤0.50 | - | ≤0.030 | ≤0.030 | - |

| JIS | SKD1 | 1.90-2.20 | 0.10-0.60 | 0.20-0.60 | 11.0-13.0 | - | ≤0.30 | - | ≤0.030 | ≤0.030 | - |

| KS | STD1 | 1.80-2.40 | ≤0.40 | ≤0.60 | 12.0-15.0 | ≤0.30 | - | ≤0.030 | ≤0.030 | - | |

| Dimensions | |||||||||||

| Round bar | |||||||||||

| Dia:20mm~650mm | Length:2000mm~5800mm | ||||||||||

| Flat bar | |||||||||||

| Thickness:20mm~650mm | Length:2000mm~5800mm | ||||||||||

| *Dimensions can be customized | |||||||||||

| Heat Treatment | |||||||||||

| Hardness | 61~54HRC | - | |||||||||

| Anneal | 870-900°C | ≤217-255HBW | |||||||||

| Quenching | 930-980°C | oil cooling | |||||||||

| Tempering | 200-540°C | 61-54HRC, tempering twice | |||||||||

| Detail information | |||||||||||

| Process | EAF+LF+VD+(ESR)+Forging+(Rolling)+Annealing Condition (optional) | ||||||||||

| Delivery Condition | Hot forged+Rough machined/turned surface | ||||||||||

| Technical Data | According to customer’s requirements of chemical composition, physical properties and mechanical testing | ||||||||||

| Ultrasonic Test | Ultrasonic test according to SEP 1921-84 G3 D/d E/d | ||||||||||

| Applications | |||||||||||

| Hot extrusion dies, forging die forging hammer, forging press die, precision forging die well as aluminum, copper and alloys die-casting mold. | |||||||||||

| Relevant documents | |||||||||||

| Contract Documents | Contract, Debit Note, PI(Performa Invoice) | ||||||||||

| Certifications | SGS, ISO9001-2008, UT(Ultrasonic Test), CO,MTC | ||||||||||

- Q: Can steel round bars be used in the telecommunications industry?

- Indeed, the telecommunications industry can make effective use of steel round bars. These bars are frequently employed to offer structural reinforcement for a range of telecommunications equipment, including antennas, satellite dishes, and communication towers. Notably resilient, these bars can withstand adverse weather conditions, rendering them well-suited for outdoor installations. Furthermore, the ease with which steel round bars can be fabricated and molded to meet precise design specifications enables the seamless integration of diverse components within the telecommunications infrastructure.

- Q: Can steel round bars be used in high temperature applications?

- Yes, steel round bars can be used in high temperature applications. Steel is known for its excellent strength and durability, even at high temperatures. However, the specific type of steel and its composition should be considered to ensure it is suitable for the particular high temperature environment and application. Additionally, proper heat treatment and other measures may be necessary to enhance the steel's resistance to high temperatures and prevent any potential degradation or failure.

- Q: Are steel round bars suitable for decorative purposes?

- Yes, steel round bars can be suitable for decorative purposes. Steel is a versatile and durable material that can be shaped and manipulated into various designs and patterns. Steel round bars can be used to create decorative elements such as railings, furniture, sculptures, and architectural details. The smooth and shiny surface of steel can add a modern and sleek aesthetic to any space. Additionally, steel is known for its strength and longevity, making it a practical choice for decorative purposes as it can withstand environmental factors and maintain its appearance over time.

- Q: Can steel round bars be used in the production of agricultural equipment?

- Agricultural equipment production can benefit from the use of steel round bars. The manufacturing industry often relies on steel due to its strength, durability, and versatility. To withstand the challenges of farming, agricultural machinery like plows, harrows, cultivators, and sprayers require robust components. Steel round bars offer a solution, as they can be used to create axles, shafts, handles, and structural supports for these machines. The high tensile strength of steel ensures that the equipment can handle heavy loads and repetitive use, which are common in agriculture. Moreover, steel can be easily welded, machined, and shaped into various forms and sizes, making it suitable for a wide range of agricultural equipment applications. In conclusion, steel round bars are both reliable and cost-effective for agricultural equipment production.

- Q: What are the advantages of using free-cutting steel round bars?

- There are several advantages to using free-cutting steel round bars. Firstly, they offer improved machinability, which means they can be easily and efficiently machined into various shapes and sizes without excessive tool wear or power consumption. This leads to increased productivity and reduced manufacturing costs. Additionally, free-cutting steel round bars have excellent chip formation properties, resulting in better surface finish and dimensional accuracy of the machined parts. They also exhibit enhanced surface hardness and wear resistance, making them suitable for applications that require durability and strength. Lastly, these bars are readily available and cost-effective, making them a preferred choice for many industries.

- Q: What are the advantages of using copper-alloy steel round bars?

- There are several advantages of using copper-alloy steel round bars in various applications. Firstly, copper-alloy steel round bars offer excellent corrosion resistance. The presence of copper in the alloy helps to protect the steel from rust and corrosion, making it suitable for use in environments with high levels of moisture or chemicals. This corrosion resistance extends the lifespan of the round bars, reducing the need for frequent replacements and maintenance. Secondly, copper-alloy steel round bars have high thermal and electrical conductivity. The copper content in the alloy enhances these properties, making them ideal for applications that require efficient heat transfer or electrical conductivity. This makes them suitable for use in electrical components, heat exchangers, and other similar applications. Another advantage of copper-alloy steel round bars is their superior machinability. Copper has excellent machinability properties, which allows for easy cutting, drilling, and shaping of the round bars. This makes them easier to work with and reduces machining time and costs. Additionally, copper-alloy steel round bars offer good strength and toughness. The steel component in the alloy provides the necessary strength to withstand heavy loads and impacts, while the copper component enhances the toughness, making them resistant to cracking or breaking under stress. This makes them suitable for use in structural applications, where high strength and durability are required. Furthermore, copper-alloy steel round bars exhibit good thermal stability. They can withstand high temperatures without losing their mechanical properties, making them suitable for applications that involve exposure to extreme heat or thermal cycling. In conclusion, the advantages of using copper-alloy steel round bars include excellent corrosion resistance, high thermal and electrical conductivity, superior machinability, good strength and toughness, and high thermal stability. These properties make them a preferred choice in various industries, including construction, electrical, automotive, and manufacturing.

- Q: How are steel round bars used in the construction of bridges and buildings?

- Steel round bars are widely used in the construction of bridges and buildings due to their strength, durability, and versatility. These bars are typically made of carbon steel and have a circular cross-section, making them perfect for structural applications. In bridge construction, steel round bars are commonly used for reinforcing concrete structures. They are often embedded within concrete beams, columns, and slabs to enhance their load-bearing capacity and resist bending and shearing forces. The bars are placed strategically in the concrete to provide tensile strength, which complements the compressive strength of the concrete. This reinforcement ensures that the bridge can withstand heavy loads and traffic while maintaining its structural integrity. Similarly, in building construction, steel round bars play a crucial role in reinforcing concrete structures. They are commonly used in the construction of columns, beams, and foundations to increase their load-carrying capacity and prevent structural failure. The bars are typically added to the concrete during the pouring process, forming a sturdy framework that enhances the building's strength and stability. Moreover, steel round bars are also used to create steel frames in the construction of buildings. These frames provide the skeletal structure of the building and support the weight of the floors, walls, and roofs. Steel round bars, due to their high strength-to-weight ratio, are ideal for creating lightweight yet robust frames that can withstand various loads, including wind and seismic forces. Additionally, steel round bars are used for other purposes in construction, such as the fabrication of steel reinforcements, connectors, and fasteners. They can be welded, bolted, or threaded to join different structural elements together, ensuring a secure and sturdy construction. Overall, steel round bars are an essential component in the construction of bridges and buildings. They provide the necessary strength, durability, and flexibility required to create structurally sound and long-lasting structures.

- Q: What are the common finishes for steel round bars?

- There are several common finishes for steel round bars, each offering unique properties and aesthetic appeal. Some of the most common finishes include: 1. Hot Rolled: This finish is achieved by rolling the steel at a high temperature, which creates a rough and scaled surface. It is commonly used for applications where a rough texture is desired, such as structural components or machinery. 2. Cold Rolled: This finish is achieved by rolling the steel at room temperature, resulting in a smoother and more polished surface. It is often used in applications where a clean and precise appearance is required, such as in the automotive or aerospace industries. 3. Turned and Polished: This finish involves machining the steel round bar to achieve a smooth and polished surface. It is typically used for decorative purposes or in applications where a high level of precision is required, such as in the manufacture of shafts or fasteners. 4. Ground: This finish involves grinding the steel round bar to remove any surface imperfections or irregularities. It results in a smooth and uniform surface, making it suitable for applications where tight tolerances or a consistent finish are essential. 5. Coated or Plated: Steel round bars can also be finished with various coatings or platings to enhance their corrosion resistance or aesthetic appeal. Common options include galvanizing, which involves applying a layer of zinc to protect against rust, or chrome plating, which provides a shiny and attractive finish. Ultimately, the choice of finish for a steel round bar depends on the specific requirements of the application, such as the desired appearance, corrosion resistance, or mechanical properties needed.

- Q: How do you check the quality of a steel round bar?

- To check the quality of a steel round bar, several factors need to be considered. Firstly, it is important to assess the bar's dimensions. This involves measuring its diameter, length, and straightness. Any deviation from the specified dimensions could indicate a lower quality bar. Next, the surface condition of the steel round bar should be inspected. It should be free from any visible defects, such as cracks, pits, or surface irregularities. Additionally, the bar's surface should be smooth and devoid of any significant roughness or burrs. Furthermore, the chemical composition of the steel round bar must be examined. This can be determined through spectroscopic analysis or other testing methods. The composition should meet the required standards and specifications, as any deviations can affect the bar's strength and durability. Another crucial aspect to consider is the mechanical properties of the steel round bar. This involves testing its tensile strength, yield strength, and elongation. These tests can be conducted using specialized machines to ensure that the bar meets the necessary strength requirements. Additionally, the steel round bar can be subjected to non-destructive testing methods, such as ultrasonic testing or magnetic particle inspection. These techniques help identify any internal or surface defects that may impact the bar's quality. Furthermore, it is essential to verify the bar's compliance with industry standards and certifications. This includes checking if the steel round bar meets the specifications set by organizations such as ASTM International or ISO. Lastly, it is advisable to consult with reputable suppliers or manufacturers who have a proven track record in producing high-quality steel round bars. They can provide documentation, certifications, and test reports to validate the quality of their products. In summary, evaluating the dimensions, surface condition, chemical composition, mechanical properties, compliance with standards, and supplier's reputation are key steps to check the quality of a steel round bar. By thoroughly examining these factors, one can ensure the reliability and performance of the steel round bar for their intended applications.

- Q: Are steel round bars suitable for conveyor belt applications?

- Depending on various factors, conveyor belt applications can benefit from the use of steel round bars. These bars are renowned for their strength, durability, and resistance to wear and tear, making them a viable choice for applications involving heavy loads, high speeds, or abrasive materials. One of the main advantages of utilizing steel round bars in conveyor belt applications lies in their ability to withstand heavy loads. Their strength ensures that the bars can support the weight of conveyed materials without bending or breaking. This is particularly crucial in industries where continuous transportation of large quantities of bulky or heavy materials is required. Moreover, steel round bars exhibit high resistance to wear and tear. The smooth surface of the bars reduces friction, resulting in minimal wear on the conveyor belt and prolonging its lifespan. This is especially important in applications where the conveyor belt constantly moves and comes into contact with abrasive materials, such as in the mining or construction industries. Additionally, steel round bars are capable of withstanding high speeds without compromising their structural integrity. Their high tensile strength enables them to handle the forces exerted on the conveyor belt during acceleration or deceleration. As a result, the conveyor system operates smoothly and efficiently, reducing downtime and enhancing productivity. However, it is crucial to consider the specific requirements of the conveyor belt application when selecting steel round bars. Factors such as the type of conveyed materials, the operating environment, and the specific load and speed requirements should be carefully evaluated. In certain cases, alternative materials or coatings may be necessary to enhance the performance and longevity of the conveyor system. In conclusion, steel round bars can be a suitable choice for conveyor belt applications due to their strength, durability, and resistance to wear and tear. Nonetheless, careful consideration of the specific application requirements is essential to ensure optimal performance and longevity of the conveyor system.

Send your message to us

Cr12 Steel Round Bars D3 Galvanized Round Bars Din1.2080 Tool Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords