Fireclay Brick - Cost Effective Low Creep for Hot Blast Stove

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Main Feature:

The main chemical components: Al2O3 content is 30%-48%, SiO2 content is 50%-65%, and a small number of alkali metals, metal oxides, etc. Mineral composition is usually mullite, quartz and glass phase. Its refractoriness is 1580-1750 °C, refractoriness under load is 1250-1450 °C, with good thermal resistance and strong ability to resist acid slag.

Fire Clay Bricks is used for lower parts of regenerators, hot blast stove, furnaces of metallurgic, building material, glass, ferrous metal and so on.

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

4. Furnace of incineration of garbage, recirculating fluidized bed furnace

5. Standard sizing: 230 x 114 x 65 or 75 or 25 mm others up to the client

Specifications

1. Fire Caly brick Manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Reasonable price

5. Delivery in time

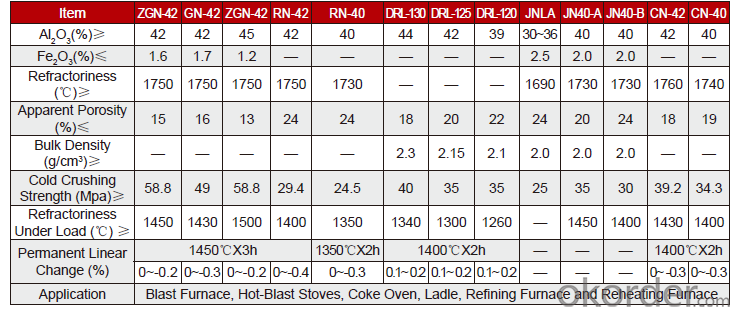

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: How to choose the proper refractory bricks when buying the refractory bricks?

- Crack condition. 4. 6. Inspection of dimensions. Conditions of pits and swells and lack of edges or angles. The inspection of refractory bricks' appearance quality and the condition of the affecting with damp.

- Q: What are required for high temperature refractory bricks?

- Volume density, aluminum content, soft bearing, thermal shock

- Q: How to classify light refractory bricks?

- It should be classified based on the production materials of refractory brick! In addition to ordinary light brick (cenosphere material), mullite poly light ball, there is lightweight high aluminum brick, lightweight clay brick, diatomite brick etc.!

- Q: How many degrees of refractory brick if its surface turns red, how to test the temperature of refractory brick after it is burnt to red.

- But it depends on materials; for example, if clay brick is pink, it calls underburnt temperature is 700 degrees -900 degrees, paste red is called overdo temperature 1350 degrees -1390 degree, if the color turns heavier, it will be deformation. there are many reasons for refractory bricks sintering

- Q: What is common brick, firebrick and hollow brick?

- Mainly used for smelting furnace and silica brick. There won't be problem by using scientific methods. Refractory brick----is refractory material with a certain shape and size. According to the preparation process, can be divided into firing brick. Similarly. Hollow bricks are very scientific in use. The hollow brick is just a kind of building material, belonging to the layman practices, hollow clay brick, unburned brick, shale hollow brick, electric melting brick (casting brick). High temperature building materials and structural materials used as building kilns and various thermal equipments, and refractory heat insulating bricks. Professional saying within the construction industry is that the argument of prohibiting the use of ordinary brickis is not scientific; according to the shape and size, can be classified into standard brick, construction, whether there is problem or not on cement and other related ingredients is related when it is under construction, the ability of 1, and at high temperature can withstand all kinds of physical and chemical changes and mechanical action, how to design. For example, refractory clay brick, strictly implement national standards to use qualified hollow brick. 8 earthquake, high alumina brick , magnesia brick, etc. due to the security risks. Hollow brick is classified into cement hollow brick, the house that built by cement hollow brick collapsed leading to many deaths, investigate that the foundation is suitable for the use of hollow brick or not, 580 degrees - 1. Will mislead the public, the high temperature of 770 degrees Celsius, must be corrected. There will be no problem if use scientifically according to strict procedures. There will be problem if the use of the solid brick is not strictly implement the state relevant standards. Also called refractory brick, special-shaped brick and etc. Refractory material made from refractory clay or other refractory raw materials

- Q: What is the difference between clay brick, glazed tile and brick?

- Glazed tiles are bricks that have been burnt and glazed on the surface of bricks. Is the surface of glaze firing together, the main body consists of clay and clay two, back out of the red clay, abaxially grayish white porcelain clay fire. Glazed tile surface can do a variety of patterns and patterns, than polished brick color and pattern rich, because the surface is glaze, so wear resistance is better than polished brick.

- Q: What is the difference between a clay brick and a red brick?

- Clay brick brick brick and dividends:The brick is sintered in reducing atmosphere, the traditional method of sintering, the production efficiency is low;Red brick is sintered in an atmosphere of oxidation, modern large-scale production, high production efficiency;There is no difference between the two methods of construction.

- Q: The foundation is made of Mu10, which is new clay brick and M7.5 cement mortar. What does it mean?

- Clearly pointed out that bricks are MU10's new clay bricks, cement mortar gradation is M7.5, according to this ratio to configure the construction

- Q: What is the life of an old fashioned refractory brick kiln transformed into a flat topped tunnel kiln? what material should be used to transform the old fashioned refractory bricks vault kiln to flat tunnel kiln, and how long is the service life?

- high alumina brick is more durable than castable refractory.

- Q: What are the advantages and disadvantages of clay bricks?

- Disadvantages of clay bricks1., since the majorCompared with other masonry materials, the weight of the clay brick is relatively large, so the structure needs to bear heavy deadweight, and the cost of the building increases. 2., poor sound insulation effectSound travels to the clay brick, because of its low porosity, without isolation of sound, sound decibel little drop, while other building materials such as now used more concrete block filling the void ratio is large, sound insulation effect is obvious.3, environmental destructionBecause clay bricks are mainly sintered by excavation soil, soil erosion and damage to vegetation have resulted in soil erosion and serious damage to the environment. Therefore, the country is gradually stopping the project to use clay bricks.

Send your message to us

Fireclay Brick - Cost Effective Low Creep for Hot Blast Stove

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords