Trane Aluminum Coil - Continuous Casting Aluminium Strip in Coils AA1050

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

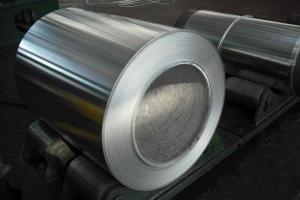

Continuous Casting Aluminium Strip in Coil is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4.Products Specification

| Alloy | Final Usage | Coil ID | Coil Weight | Thickness |

| AA1050 | Aluminium coil/circle | 610mm +/-10mm | Min 5 tons | 3-8mm |

5. FAQ

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What are the potential environmental impacts of aluminum coil production?

- The potential environmental impacts of aluminum coil production include deforestation due to the extraction of bauxite, water pollution from the chemicals used in the refining process, air pollution from the release of greenhouse gases during smelting, and energy consumption, as aluminum production requires a significant amount of electricity. Additionally, the disposal of waste materials and by-products can contribute to soil contamination if not managed properly.

- Q: What are the common surface preparation methods for aluminum coils?

- To prepare aluminum coils for use, it is necessary to engage in common surface preparation methods such as cleaning, degreasing, and etching. In the surface preparation process, cleaning is typically the initial step. Its purpose is to eliminate any dirt, dust, or other impurities from the surface. Various techniques can be employed for cleaning, including the use of solvents, alkaline cleaners, or mechanical methods like brushing or scrubbing. Degreasing is another crucial aspect of aluminum coil preparation. Its objective is to eliminate any oils or greases that may be present on the surface. Degreasing can be accomplished by employing solvents or alkaline cleaners specifically designed for this purpose. Thorough removal of grease or oils is vital as they can interfere with subsequent treatments and coatings. Etching is commonly performed on aluminum coils to enhance adhesion for subsequent coatings or treatments. It involves creating a roughened surface. Etching can be carried out using chemical etchants or mechanical methods like sandblasting. The choice of etching technique depends on the specific application requirements and desired surface finish. Following surface preparation, additional treatments can be applied to aluminum coils, such as conversion coatings or anodizing, to enhance corrosion resistance or improve surface properties. These treatments safeguard the aluminum surface and provide a foundation for further finishes or coatings. In summary, proper surface preparation plays a critical role in achieving optimal adhesion, corrosion resistance, and overall performance of aluminum coils in diverse applications. It ensures that the surface is clean, free from contaminants, and appropriately prepared for subsequent treatments or coatings.

- Q: How are aluminum coils used in electrical applications?

- Aluminum coils are extensively used in electrical applications due to their excellent conductivity and lightweight properties. They are primarily used in transformers, motors, inductors, and generators, where their high electrical conductivity efficiently transmits and distributes electric currents. Additionally, their lightweight nature allows for easy installation and reduces the overall weight of electrical equipment.

- Q: Are aluminum coils applicable in the manufacturing process of automobiles?

- <p>Yes, aluminum coils are widely used in automobile manufacturing. They are utilized in various components such as engine parts, body panels, and wheels due to their lightweight, corrosion resistance, and strength. Aluminum's recyclability and energy efficiency also make it an environmentally friendly choice for the automotive industry.</p>

- Q: Are aluminum coils suitable for heat exchangers?

- Yes, aluminum coils are suitable for heat exchangers. Aluminum has excellent thermal conductivity, corrosion resistance, and lightweight properties, making it an ideal material for heat transfer applications. Aluminum coils can efficiently transfer heat between fluids in heat exchangers, making them a popular choice in various industries.

- Q: How are aluminum coils used in the aerospace industry?

- Aluminum coils find extensive application in the aerospace industry for various purposes. The construction of aircraft structures is one primary area where aluminum coils are heavily utilized. Aluminum, being a lightweight material with an exceptional strength-to-weight ratio, is an ideal choice for the aerospace industry, where weight reduction is of utmost importance. These coils are often transformed into sheets or plates and employed in the fabrication of aircraft fuselage, wings, and other structural elements. Apart from their structural uses, aluminum coils also find application in the manufacturing of heat exchangers and cooling systems within aircraft. Aluminum's high thermal conductivity and resistance to corrosion make it an outstanding material for dissipating the heat produced by engines and electronic systems. These coils can be molded into tubes or fins, enabling efficient heat transfer and ensuring optimal performance of the aircraft's cooling systems. Another significant application of aluminum coils in the aerospace sector lies in electrical uses. Aluminum, being a good conductor of electricity, is utilized in the production of electrical wiring, connectors, and cables. These components are crucial for the proper functioning of various systems within an aircraft, including power distribution, communication, and navigation systems. Furthermore, aluminum coils are also employed in the construction of fuel tanks and hydraulic systems in aircraft. The corrosion resistance and ability of aluminum to withstand high pressure and temperature make it a reliable choice for these critical elements. By shaping and welding the coils, tanks or piping systems can be created to store and transport fuel and hydraulic fluids effectively and safely. In conclusion, aluminum coils play a crucial role in the aerospace industry by providing lightweight, robust, and corrosion-resistant materials for various applications, including structural, thermal, electrical, and fluid management purposes. Their versatility, durability, and exceptional performance characteristics make them indispensable in the design and construction of modern aircraft, ensuring safety, efficiency, and reliability in air transportation.

- Q: How are aluminum coils used in rainwater harvesting systems?

- Aluminum coils are commonly used in rainwater harvesting systems for their durability and efficient heat transfer properties. These coils are typically installed within the rainwater storage tanks and are connected to a heat exchanger system. The primary function of the aluminum coils in rainwater harvesting systems is to facilitate the heating or cooling of the stored rainwater, depending on the intended use. For instance, if the harvested rainwater is intended for domestic use, such as for showers or laundry, the aluminum coils can help heat the water to a desired temperature. On the other hand, if the harvested rainwater is intended for cooling purposes, such as air conditioning or industrial processes, the coils can help cool the water as well. The aluminum coils are designed in a way that maximizes the surface area exposed to the rainwater, allowing for efficient heat transfer. This means that the coils can rapidly absorb or release heat, depending on the needs of the system. The aluminum material used for these coils is preferred due to its high thermal conductivity, corrosion resistance, and lightweight properties. Additionally, the coils are also beneficial in preventing the growth of bacteria and algae within the rainwater storage tanks. Aluminum has natural antimicrobial properties that inhibit the growth of these organisms and ensure the harvested rainwater remains clean and safe for use. Overall, aluminum coils play a crucial role in rainwater harvesting systems by enhancing the usability of the collected rainwater through efficient heat transfer and maintenance of water quality.

- Q: Can aluminum coils be used in the production of aluminum downspouts?

- Yes, aluminum coils can be used in the production of aluminum downspouts. Aluminum coils are typically made from high-quality aluminum alloy and are rolled into thin sheets. These coils can then be cut and formed into various shapes and sizes, including downspouts. Aluminum is a popular choice for downspouts due to its lightweight, durable, and corrosion-resistant properties. Additionally, aluminum coils can be easily manipulated and shaped to meet specific design requirements, making them suitable for manufacturing aluminum downspouts.

- Q: What are the different coil handling equipment options for aluminum coils?

- When it comes to handling aluminum coils, there are several equipment options available that cater to the specific requirements and preferences of the user. Here are some commonly used options: 1. Coil Lifters: Specially designed lifting devices, coil lifters efficiently and securely handle aluminum coils. They typically consist of clamps or hooks attached to a lifting mechanism. Coil lifters can be manually operated or powered by electricity or hydraulics, ensuring ease of use and increased productivity. 2. Coil Tippers: Used for rotating or tilting aluminum coils, coil tippers facilitate loading, unloading, and positioning. Equipped with adjustable arms or clamps, they securely hold the coil during rotation. Control options include manual or hydraulic and electric systems for precise movements. 3. Coil Cars: Coil cars are transport vehicles designed for moving aluminum coils within a manufacturing facility or between areas. They have a platform or carriage where the coil is placed, and various mechanisms for loading, unloading, and positioning. Coil cars can be manually operated or powered by electricity or hydraulics, enhancing efficiency. 4. Coil Turnstiles: For safe and efficient storage and retrieval of aluminum coils in a vertical position, coil turnstiles are used. They typically consist of a rotating drum or spool capable of holding multiple coils, providing easy access. Coil turnstiles can be manually operated or powered by electricity or hydraulics, offering quick and convenient storage solutions. 5. Coil Cradles: Coil cradles are used to support and protect aluminum coils during storage or transportation. They feature a sturdy frame or structure with adjustable arms or supports that securely hold the coil. Coil cradles can be customized to accommodate different coil sizes and weights, ensuring safe and stable handling. In conclusion, these coil handling equipment options offer various solutions for efficient and safe handling of aluminum coils, improving manufacturing processes and productivity. The choice of equipment depends on factors such as coil size, weight, specific operation requirements, and available budget.

- Q: I have a edelbrock aluminum intake that was sitting around for a year and it has some fading with a little corrosion. What's a good cleaner or chemical I can use to clean it up?

- Bare aluminum surfaces tend to corrode and go dull when left exposed to the air. That's just the way things are. If you want. you could use a lot of elbow grease and a metal polishing compound like Simichrome to shine up your manifold, then spray it with clear-coat paint to help keep it bright. Just be sure that if you do use clear-coat paint, that it will stand up to the high temperatures of your engine compartment.

Send your message to us

Trane Aluminum Coil - Continuous Casting Aluminium Strip in Coils AA1050

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords