All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is the thickness of aluminum coils measured and controlled during manufacturing?

The thickness of aluminum coils is typically measured and controlled during manufacturing through a process called gauge control. This involves using specialized equipment, such as thickness gauges, to measure the thickness of the coils at various points along the production line. These measurements are then compared to the desired thickness specifications, and any deviations are corrected by adjusting the manufacturing parameters, such as the rolling speed or tension, to ensure the coils meet the required thickness standards.

How does the temper of aluminum coils affect their properties?

The temper of aluminum coils significantly affects their properties. Different temper designations result in varying levels of hardness, strength, formability, and other mechanical properties. For example, a fully annealed temper will have lower strength and higher ductility, making it easier to form and shape. On the other hand, a harder temper like H32 or H34 will have increased strength and resistance to deformation, but with reduced ductility. Therefore, the temper selection is crucial in determining the suitability of aluminum coils for specific applications and their ability to withstand different environmental and processing conditions.

Can aluminum coils be used for food packaging?

Yes, aluminum coils can be used for food packaging. Aluminum is a popular choice for food packaging due to its various beneficial properties such as being lightweight, resistant to corrosion, and impermeable to moisture, oxygen, and light. It helps in preserving the quality and freshness of the packaged food products.

What are the main testing methods for aluminum coil quality?

The main testing methods for aluminum coil quality include visual inspection, chemical analysis, mechanical testing, and non-destructive testing. Visual inspection involves checking for surface defects such as scratches, dents, or color variations. Chemical analysis is done to determine the composition and purity of the aluminum, ensuring it meets the required specifications. Mechanical testing involves assessing physical properties like tensile strength, elongation, and hardness to ensure the coil's structural integrity. Non-destructive testing methods like ultrasonic testing or eddy current testing are used to identify internal defects or inconsistencies without damaging the coil.

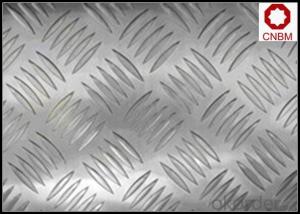

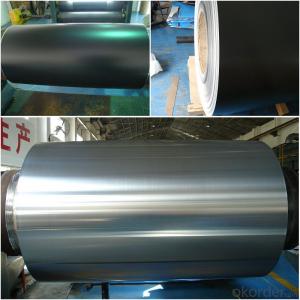

Wholesale Aluminum Coils from supplier in Madagascar

Thank you for choosing us as your premier supplier of Aluminum Coils in Madagascar. We are committed to providing you with top-notch sales, quotations, and technical support services. As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and expertise to meet all your Aluminum Coils needs.

Our extensive range of Aluminum Coils products ensures that we can cater to your specific requirements. Whether you need standard or customized options, we have the solutions for you. With our deep understanding of the local market in Madagascar, we can provide invaluable insights and expertise to ensure the success of your projects.

Customer satisfaction is our top priority, and we strive to deliver exceptional quality products and services. With our vast industry experience and global presence, we are well-equipped to cater to your unique needs and ensure a seamless procurement process.

We invite you to join us today and experience the convenience and reliability of our one-stop Aluminum Coils procurement services. Let us be your trusted partner in achieving success in your endeavors. Contact us now to discuss your requirements, and our team will be there to assist you every step of the way.

Our extensive range of Aluminum Coils products ensures that we can cater to your specific requirements. Whether you need standard or customized options, we have the solutions for you. With our deep understanding of the local market in Madagascar, we can provide invaluable insights and expertise to ensure the success of your projects.

Customer satisfaction is our top priority, and we strive to deliver exceptional quality products and services. With our vast industry experience and global presence, we are well-equipped to cater to your unique needs and ensure a seamless procurement process.

We invite you to join us today and experience the convenience and reliability of our one-stop Aluminum Coils procurement services. Let us be your trusted partner in achieving success in your endeavors. Contact us now to discuss your requirements, and our team will be there to assist you every step of the way.