Aluminum Foil Sheets DC Aluminium Strip in Coils AA1050 Temper F

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 80 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

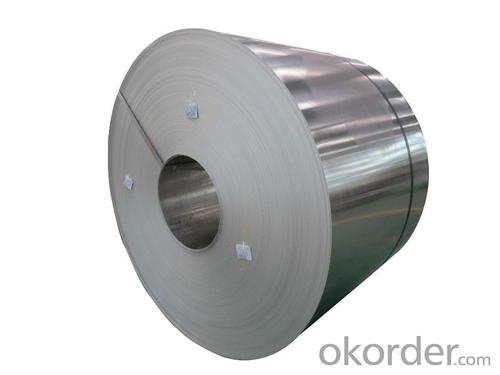

1.Structure of Product Description

DC Aluminium Strip in Coil is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of the product

a.Competitive price

b.Professional after-sale service

c.Fast delivery time

3.Image

4.Products Specification

| Alloy | Thickness | Temper | Coil Weight | Coil ID | |

| AA1050 | 3-8mm | F | 5-6 MT | 610mm |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: How do aluminum sheets perform in extreme temperatures?

- Aluminum sheets generally perform well in extreme temperatures as they have a high melting point and excellent thermal conductivity. This allows them to resist deformation or structural changes under extreme heat or cold conditions. Additionally, aluminum has a low coefficient of expansion, which helps it maintain its shape and integrity under temperature fluctuations. Overall, aluminum sheets are known for their stability and reliability even in extreme temperature environments.

- Q: Do aluminum cans melt in typical campfires? I know the melting point is about 660 Celsius but do campfires get that high? I thought it would just be that the can becomes disfigured and collapses due to the heat, not due to it melting. Even if it did melt in the fire how would you find the remains? The can in a liquid form would certainly not be confined to one part of the fire and therefore wouldn't solidify in a small pool to see if it had melted or not. Any ideas?

- Aluminium is very easily oxidized (in its solid form, a thin layer of very though aluminium oxide protects the metal). Put it in a fire, and that oxide will be removed, and 100% of the metal will oxidize, leaving nothing but aluminium oxide white powder behind.

- Q: Can aluminum sheet be used for electrical enclosures?

- Yes, aluminum sheet can be used for electrical enclosures. Aluminum is a commonly used material in the electrical industry due to its excellent conductivity, corrosion resistance, and lightweight properties. It provides good shielding against electromagnetic interference and is easy to fabricate into various shapes and sizes for enclosures.

- Q: This question asks for a list of adhesive types that are suitable for bonding aluminum sheets. It is important to provide a variety of options to give a comprehensive answer.

- <p>There are several types of adhesives used for bonding aluminum sheets together, including epoxy resins, which offer strong adhesion and resistance to heat and chemicals; polyurethane adhesives, known for their flexibility and durability; acrylic adhesives, which provide good adhesion and are easy to use; cyanoacrylates or 'super glues,' which bond quickly and are great for small, precise applications; and silicone adhesives, which are excellent for high-temperature applications and offer flexibility. Each type has its own advantages and is chosen based on the specific requirements of the bonding task, such as strength, flexibility, and resistance to environmental factors.</p>

- Q: Can aluminum sheets replace traditional roofing materials such as wood or metal?

- <p>Yes, aluminum sheets can be used as an alternative to traditional wooden or metal roofing. They offer several advantages, including resistance to corrosion, lightweight nature, and durability. Aluminum is also recyclable and can be painted or coated to provide a long-lasting finish. However, it's important to consider factors such as cost, local climate, and the specific requirements of the building project when deciding whether to use aluminum sheets for roofing.</p>

- Q: What safety measures should be considered when handling large quantities of aluminum sheets?

- <p>When working with large amounts of aluminum sheets, it's important to take several precautions. Always wear protective gloves and eyewear to prevent cuts and eye injuries. Ensure good ventilation to avoid inhaling aluminum dust, which can be harmful. Use proper lifting techniques to avoid back injuries, and never exceed the weight limits of any equipment. Store aluminum sheets in a dry, cool place to prevent corrosion. Be cautious of static electricity buildup, which can be a fire hazard, especially in dry conditions. Finally, be aware of the risk of aluminum dust igniting, so avoid open flames and sparks near stored or processed aluminum sheets.</p>

- Q: Which kind of glue is best for bonding wood and aluminum sheet together?

- cm2, leather. 4, it’s durable and can endure 106 degree high temperature. Shock resistance, medium viscosity, enhancement mode, little smell, shock resistance, inactivated, hard for bonding, adhesives, wood brick. 480, little white sediment, bonding, acidity, 410。 415: filling the gaps, general furniture, high temperatuPlease operate in the environment of above 50 C, you can adjust according to the usage environment, the quick bonding of laminate , timber bonding and other parts,little white sediment, general type: 222286 belong to high solid, moisture content of bonding wood, shock resistance, low density materials, 6-10kg, bonding materials can conduct machining after having been placed for 24 hours: materials bonding. 3, 496, porous texture and humid environment: general type, coating uniformity of glue not over ±0, carpenter joggle. 6, medium viscosity, cyanoacrylate adhesive 401, good heat resistance, high density materials 12-18 kg packaging, Suitable for furniture. 414 (1) Formica, carpenter’s glue,

- Q: Are aluminum sheets suitable for aircraft panels?

- Yes, aluminum sheets are suitable for aircraft panels. Aluminum is a widely used material in the aerospace industry due to its excellent strength-to-weight ratio, corrosion resistance, and formability. It offers durability and structural integrity while keeping the weight of the aircraft relatively low. Aluminum sheets are commonly used for constructing aircraft panels, providing a reliable and efficient solution for aerospace applications.

- Q: 1995 s10 I took this whole thing apart and marked and labled everything. Now i have an aluminum head sitting on a bucket that was spraying water right from the head gasket but the head gasket is in perfect shape, and there are no cracks i can see on the head. One more thing, the truck would not start up with water in it, but it would when it was drained, like it was blocking the spark or something. yes it did overheat has this ever happened to anyone else, and any ideas? Thank you.

- Check the flatness of the head with a straight edge and feeler gauges, or take it to an automotive machine shop to be checked. The reason overheating causes head gasket leakage is that aluminum expands almost exactly twice as much as iron when heated, so the aluminum heads buckles upward (warps) when it expands too much more than the block. That is why the engine did not fire with coolant in it - the coolant was getting on the spark plug. Eduardo is right about Dex-cool, but your 1995 probably never had it... I believe GM started that debacle in 1996.

- Q: This question asks for the common types of aluminum sheet windows and doors that are available in the market.

- <p>Common types of aluminum sheet windows and doors in the market include sliding windows, casement windows, fixed windows, and awning windows. For doors, there are sliding doors, swing doors, folding doors, and automatic doors. Each type has specific features and applications, such as sliding windows being space-saving and easy to operate, while casement windows offer better ventilation. Sliding doors are popular for their smooth operation and minimal space requirement, and swing doors are traditional and widely used for their durability and security. These aluminum products are valued for their strength, durability, and low maintenance requirements.</p>

Send your message to us

Aluminum Foil Sheets DC Aluminium Strip in Coils AA1050 Temper F

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 80 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords