Colour Coating Galvanized Steel Coils for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Colour Coating Galvanized Steel Coils for Construction

1.Structure of Colour Coating Galvanized Steel Coils for Construction

1. Colour Coating Galvanized Steel Coils for Construction with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

2. Colour Coating Galvanized Steel Coils for Construction consist of cold rolled, HDG electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of Color Coated Steel Coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. Colour Coating Galvanized Steel Coils for Construction has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. Colour Coating Galvanized Steel Coils for Construction can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

2.Main Features of Colour Coating Galvanized Steel Coils for Construction.

1) Rust-proof

2) Water-proof

3)Durable using

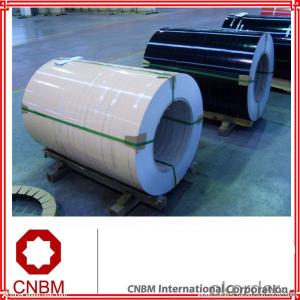

3. Colour Coating Galvanized Steel Coils for Construction Images

4. Colour Coating Galvanized Steel Coils for Construction Specification

1)Based raw material: Hot rolled steel coils or Cold rolled steel coils

2) Thickness

3) Width

4)Coating mass

5) Spangle

6)Surface treatment

7)Coil inner diameter

8)Painting kind

9)Painting color

10)Painting thickness

Detail information:

1: Size: 0.15-1.2mm*600-1250mm

2: Paint: Top side: 15-25um, Back side: 5-9um, or according to customer’s order.

3: Base material: Hot dipped galvanized steel coil, GL

4: Zinc coating: 60g-275g.

5: Coil weight: 3-6tons

6: Coil ID: 508mm

7: Color: Any color.

8: Standard: ASTM, GB, JIS

9:Grade: CGCC,CGCH,SGCC, DX51D and ASTM

10:Surface Treatments: skin passed, chromated, oiled and antifinger

11: Approved Certificate: SGS / ISO9001 / BV

12: Package Method: Vertical/Horizontal, full wrapped with anti-moist paper inside, iron sheet (sea worthy)

13: Payments terms: T/T ,L/C,etc.

5.FAQ of Colour Coating Galvanized Steel Coils for Construction

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How is the packaging and delivery?

Exporting Package with the steel material cover and the delivery term is based on the project.

- Q: How are steel coils used in the manufacturing of shipping containers?

- Steel coils are used in the manufacturing of shipping containers as they provide strength, durability, and structural integrity. These coils are transformed into sheets, which are then cut, shaped, and welded to construct the container's body and roof panels. The steel coils ensure that the container can withstand the rigors of transportation, protect the cargo inside, and endure various weather conditions.

- Q: Hi my dad bought a stain steel refridg. yesterday, and we went to clean it and it looks all streaky and gets finger prints and stuff on it too easily we used mr clean multisurface cleaner and it didnt work to well is there a certain type of cleaner we are supposed to use?

- I use a good car wax/chrome polish

- Q: How are steel coils inspected for flatness variations?

- Steel coils are inspected for flatness variations using specialized equipment such as laser or optical scanning systems. These systems measure the surface profile of the coil and identify any deviations from the desired flatness. The data collected is then analyzed to determine the extent of the variations and whether they meet the required tolerances.

- Q: Several reading methods of steel tape measure

- Direct reading method when measuring the steel tape zero scale alignment measurement starting point, proper tension (stretching force with steel tape tension or tension on the calibration ruler identification shall prevail, with the spring balance measure), direct reading measurement end point corresponding to the scale scale.

- Q: could anybody tell me the the weight of a cubic metre of mild steel? and where to get this info from?

- i thnk 7.85 the density of ms is 7.85 kg/cm2 and formula is density=mass/volume u have volume=1m3 7.85*1=mass so 7.85 kg

- Q: What are the different types of steel coil cutting machines?

- In the market, there is a wide range of steel coil cutting machines available, each tailored to meet specific needs and requirements. Some commonly used types include: 1. Slitting Machines: These machines are utilized to cut steel coils into narrower strips. Equipped with multiple circular blades, they are capable of making precise cuts along the length of the coil, enabling the production of narrower coils or strips. 2. Cut-to-Length Machines: Designed to cut steel coils into specific lengths, these machines possess the ability to accurately measure and cut the coil to the desired length, ensuring uniformity and precision. 3. Rotary Shears: Rotary shears are robust cutting machines that can handle thicker and larger steel coils. Utilizing a rotating blade, they are suitable for cutting thicker gauge materials. 4. Multi-Blanking Machines: Intended for cutting steel coils into multiple smaller blanks simultaneously, these machines have the capability to cut the coil into various shapes and sizes. This makes them ideal for producing multiple parts from a single coil. 5. Slit and Cut-to-Length Combination Machines: These machines integrate the functionalities of both slitting and cut-to-length machines, enabling the cutting of narrow strips and lengths in a single process. They offer versatility and efficiency, saving time and increasing productivity. Each type of steel coil cutting machine possesses distinct advantages and is suitable for specific applications. The choice of machine depends on factors such as coil thickness, desired strip width, required length accuracy, and production volume.

- Q: What is the purpose of coating steel coils?

- The purpose of coating steel coils is to provide a protective layer that prevents corrosion and enhances the durability and lifespan of the steel.

- Q: I'm searching for the elastic modulus of ASTM A653 galvanized steel sheet. Max points for first person with a response that includes web address of reliable reference - I just haven't found it yet. thanks!

- Aluminum is non ferrous so a magnet won't persist with it, and this is softer than steel. once you have desperate that, if it has previous paint on it, this is particularly helpful to apply a primer that corresponds to the paint you would be utilising the two vinyl or oil based, then paint. this is possibly no longer Galvanized, yet whilst this is, the unpainted floor with have a 2 colour steel Spackle look.

- Q: How are steel coils used in the production of industrial tanks?

- Steel coils are used in the production of industrial tanks as they are rolled and shaped into the desired form, providing the necessary strength and durability for the tank structure.

- Q: I want to make a stock removal knife, but I am really confused about what steel to use. I am just a beginner but I read o1 steel is great? Also I am kind of on a budget.

- 01 tool steel is easier to work with. You need to contact places like Pop Knives and Supplies out of Washington, Georgia or Sheffield Steel out of Florida, I made custom knives for years with my husband. Made alot with ATS-34 Stainless. Look at links on my website source.

Send your message to us

Colour Coating Galvanized Steel Coils for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords