Color Steel Color Rolled/ Printed Color Galvanized Steel Coilfor Sandwich wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Military Printed Color Galvanized Steel Coil

1. Techinical standard: EN10169

2. Grade: TDX51D, TSGCC

3. Color: Ral standard or according to customers' requirment

4. Thickness: 0.14-0.8mm (the most advantage thickness)

5. Width: 600-1250mm (610/724/820/914/1000/1200/1219/1220/1250)

6. Base metal: Galvanized / galvalume steel / cold rolled

7. Finish Painting: 15-20miu PE on top

Back painting: 5-8miu EP on back

8. Type of PPGI: PPGI with military pattern

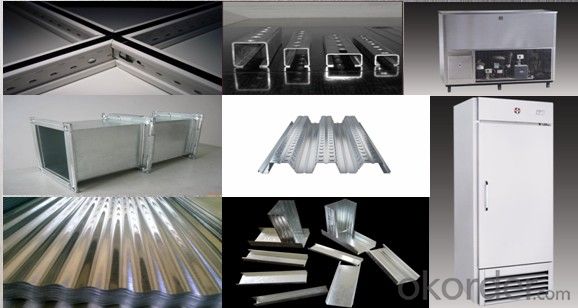

Product category and properties: The products can be divided into the following sorts in the light of their specific manufacturing and processing methods:

1. Hot-dip galvanized steel coil. Its the most common galvanized steel product at present.

2. Hot-dip galvalume steel coil. Al-Zn galvanized steel sheet. General use, construction industry, household appliance industry, automobile industry and industrial instruments.

3. Color coating steel coil. Any color according to the requests of customers. General use, for drawing, structure, construction industry (outdoor), factory building, agricultural warehouse, prefabricated ports of residence, title roof and furniture appliance.

4. Guardrail. Highway guardrail/fence can be used for both sides of highway and road. Available in any different sizes. Hot-dipped galvanized or galvalume steel sheet. Spraying plastics in your exact specifications.

| Back painting: | 5-7 mic. EP |

| Color: | According to RAL standard |

| commodity | Color-coated Galvanized Steel Coil (PPGI/ PPGL) |

| Techinical Standard: | JIS G3302-1998, EN10142/10137, ASTM A653 |

| grade | TSGCC, TDX51D / TDX52D / TS250, 280GD |

| Types: | For general / drawing use |

| Thickness | 0.14-1.0mm(0.16-0.8mm is the most advantage thickness)) |

| Width | Width: 610/724/820/914/1000/1200/1219/1220/1250mm |

| Type of coating: | PE, SMP, PVDF |

| Zinc coating | Z60-150g/m2 or AZ40-100g/m2 |

| Top painting: | 5 mic. Primer + 15 mc. R. M. P. |

| ID coil | 508mm / 610mm |

| Coil weight: | 4--8MT |

| Package: | Properly packed for ocean freight exportation in 20' ' containers |

| Application: | Industrial panels, roofing and siding for painting / automobile |

| Price terms | FOB, CFR, CIF |

| Payment terms | 20%TT in advance+80% TT or irrevocable 80%L/C at sight |

| delivery time | 25 days after recepit of 20% TT |

| Remarks | Insurance is all risks |

| MTC 3.1 will be handed on with shipping documents | |

| We accept SGS certificatation test |

Q&A What is the validity of your quotation?

ANSWER: Normally 2 days

- Q: I felt that my nylon strings don't sound as good as steel ones. Is it okay that I replace them with steel ones, even if my guitar is classical? Thanks.

- No, you will damage the guitar,it was not create to stand the force on the neck that steel strings will put on it.

- Q: I have a belly button piercing and the metal is stainless steel.. I was wondering does it develop rust whenever you go shower and clean it? Can I still swim in the summer with it or do I have to take it out? What happens if I swim in the pool with it?

- Theoretically stainless steel is supposed to be what it's name says it is - stainless. However there are different grades of stainless so yours might dis-colour if it's low grade. Think of all the stainless steel cutlery you use to eat with - if you keep it clean it doesn't go rusty ; it can if you don't look after it.

- Q: What are the advantages of using galvanized steel coils?

- There are numerous advantages to using galvanized steel coils in various applications. Firstly, galvanized steel coils are highly resistant to corrosion. The process of galvanization involves coating the steel with a layer of zinc, which acts as a protective barrier against moisture, chemicals, and other elements that can cause rust and corrosion. This makes galvanized steel coils ideal for outdoor applications where they will be exposed to harsh weather conditions or corrosive substances. Secondly, galvanized steel coils have excellent durability and longevity. The zinc coating provides an extra layer of protection to the steel, making it more resistant to wear and tear. This means that galvanized steel coils have a longer lifespan compared to other types of steel, reducing the need for frequent replacements and saving costs in the long run. Additionally, galvanized steel coils have high strength and structural integrity. The zinc coating not only provides corrosion resistance but also enhances the overall strength of the steel. This makes galvanized steel coils suitable for applications that require a strong and reliable material, such as construction, automotive, and industrial manufacturing. Furthermore, galvanized steel coils are easy to work with and require minimal maintenance. The zinc coating provides a smooth and uniform surface, making it easier to paint, weld, and fabricate. Unlike other coatings or finishes, galvanized steel coils do not require regular maintenance or additional protective measures, reducing the time and effort needed to keep them in good condition. Lastly, galvanized steel coils are environmentally friendly. The zinc coating used in galvanization is a recyclable material, making it a sustainable choice for various industries. Additionally, the long lifespan of galvanized steel coils reduces the need for frequent replacements, reducing waste and the overall environmental impact. In conclusion, the advantages of using galvanized steel coils include corrosion resistance, durability, high strength, easy workability, low maintenance, and environmental sustainability. These benefits make galvanized steel coils a popular choice in a wide range of applications, from construction and manufacturing to automotive and infrastructure projects.

- Q: How are steel coils used in the production of industrial boilers?

- Steel coils are used in the production of industrial boilers to form the main body and components of the boiler, such as the shell, tubes, and headers. The coils are shaped and welded together to create a strong and durable structure that can withstand high pressure and temperature conditions. Additionally, the use of steel coils ensures the boiler's efficiency and longevity, as steel is known for its excellent heat transfer properties and resistance to corrosion.

- Q: I have two theories, which one's correct?My book says that steel is made up of 98% iron and 2% carbon.98% of iron's molar mass (55.85 g/mol) is 54.733.2% of carbon's molar mass (12.01 g/mol) is .2402.If you add them up that gives you that steel has a molar mass of 54.97 g/mol.However, steel's chemical formula is Fe(3)CThat would make it's molar mass 179.56 g/mol.( Because 3(55.85) + 12.01 = 179.56 )Which one is correct?

- Molar Mass Steel

- Q: where can i get a thick sheet of steel ? and is steel bullet proff for example if you shoot a bullet on steel will that bullet bounce right off the steel ?

- Try the business-to-business yellow pages in your area. A local hardware store can also tell you who to contact. Or search steel plate or sheet metal on the internet to find a local supplier. No, sheet steel is not bullet proof, unless you get heavy plate. Depending on how thick it is, the plate will deform if hit by a high velocity bullet, but usually not enough to matter. Bullets have velocities from about 500 ft/sec up to roughly 3000 ft/sec, depending on the type of weapon used. I wouldn't try to use anything thinner than 3/4 inch. You'll have to experiment and see what it will actually stop. I can't guarantee it'll stop a high-velocity rifle slug. Try it and see.

- Q: How are steel coils inspected for edge quality?

- Steel coils are inspected for edge quality through a combination of visual inspection and non-destructive testing methods. Visual inspection involves a thorough examination of the edges of the coils to identify any visible defects such as cracks, chips, or uneven edges. This is typically done by trained inspectors who carefully inspect the entire length of the coil. Non-destructive testing methods are also used to detect any hidden defects or imperfections in the edges of the steel coils. These methods include ultrasonic testing and magnetic particle inspection. Ultrasonic testing involves the use of high-frequency sound waves to identify any internal flaws or discontinuities in the steel. Magnetic particle inspection, on the other hand, uses magnetic fields and particles to identify any surface or near-surface defects in the steel. Both visual inspection and non-destructive testing methods play a crucial role in ensuring the edge quality of steel coils. By conducting these inspections, manufacturers can identify and address any defects or imperfections in the edges of the coils, ensuring that they meet the required quality standards.

- Q: How are steel coils used in the manufacturing of railway tracks?

- Steel coils are used in the manufacturing of railway tracks as they are processed into long, continuous lengths of steel rails. These coils are first uncoiled and then passed through a series of machines that shape, cut, and weld them together to form the required lengths and profiles of railway tracks.

- Q: I wasn't expecting much because i knew it was cheap (Trying to avoid high prices) But anyway i cut a few bottles and cans and i noticed the very edge of the blade was starting to bend. I ignored it and tried it on a 3 inch limb, and the whole blade bent sideways where the limb hit it.I heard cold steel was supposed to be top quality and I wanted to know how durable their swords are and if they're worth it. Thanks!

- O.Adequate. First and fundamental it takes coaching and observe to use a katana. There may be a little bit component known as 'system'. You need to to search out an trainer. Except you're a fairly significant man, an O Katana is conveniently too large for you. Weapons of this way were not used for dueling, they have been further anti-cavalry weapons. As a substitute cumbersome for one in the direction of one combat. The cold steel katanas are not very regularly correct varieties of a japanese sword - missing finesse and poorly balanced. They are going to take a beating though and it seems like that's what you probably giving it. Severely, you possibly more often than not a hazard to your self and possible others round you - to search out an teacher.

- Q: What are the factors affecting the formability of steel coils?

- The factors affecting the formability of steel coils include the composition and microstructure of the steel, the thickness and width of the coil, the temperature and speed of the forming process, the lubrication used during forming, and the presence of any surface defects or contaminants.

Send your message to us

Color Steel Color Rolled/ Printed Color Galvanized Steel Coilfor Sandwich wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords