Color Printed Stand Up Laminted Bag with Zipper for Packing

- Loading Port:

- Shanghai

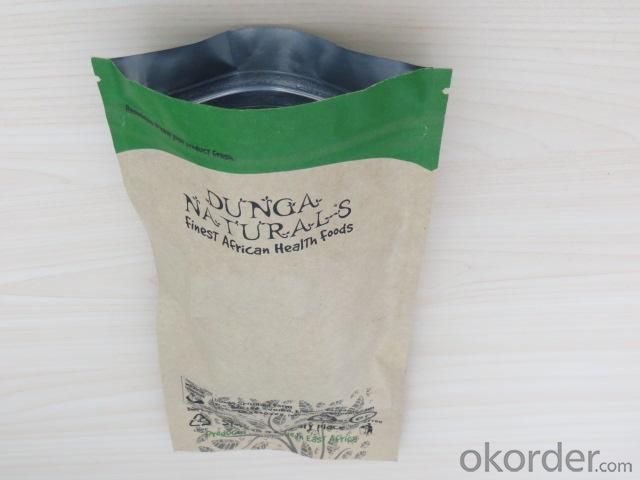

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Color Printed Stand Up Laminated Bag with Zipper for Packing:

Color Printed Stand Up Laminated Bag with Zipper for Packing are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Color Printed Stand Up Laminated Bag with Zipper for Packing mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Color Printed Stand Up Laminated Bag with Zipper for Packing:

Excellent quality control

Experienced factory produced

SGS passed

3. Color Printed Stand Up Laminated Bag with Zipper for Packing Used for Packing Photos:

4. Color Printed Stand Up Laminated Bag with Zipper for Packing Specification:

1. Material: PE, LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Color Printed Stand Up Laminated Bag with Zipper for Packing:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What products need plastic packing bags?

- Need to use plastic bags do not have too much garbage bags, food bags, beverage bags, commodity bags, clothing bags, plastic bags are closely related to human, as long as you want, we can use plastic bags for packaging, plastic just different ingredients. Because plastic bags are convenient to carry and relatively low cost, they are well known to people.

- Q: What is the material of detergent bag?

- Most of these bags are made of PP, PE, OPP, BOPP plastic raw materials. In general, families rarely recycle, just waste or garbage.

- Q: Duck sauce made of pure aluminum foil vacuum packaging bag or transparent plastic?

- A good vacuum packing is recommended.

- Q: What is the material for edible fungus stick packing bag?

- High pressure polypropylene bag, the bag has the characteristics of high temperature and high pressure, it can reach 120 degrees and not easily deformed. It is the first choice for factory cultivation.

- Q: How are food bags made out?

- Packaging design: This is based on the requirements of the food company to design the layout of the food packaging bag, that is, the pattern of food packaging bags. A good design layout of food packaging bags can improve the sales of products. After all, the first eye is still very important. This pattern is generally designed by the food company and then given to the manufacturer of the bags.

- Q: The vacuum packing bag is sealed. How can I open the zipper?

- In addition to wax, you can also use lubricating oil, to pick a relatively transparent, clean kind of, in the zipper ring drop a few drops, repeated several times, can also achieve smooth purposes.

- Q: What are the packaging forms of fresh milk?

- Pasteurized milk as milk sterilization, the glass bottle packaging plastic bags or plastic bottles, plastic bags are simple, like using the monolayer polypropylene material, because these materials are difficult to achieve in aseptic filling and sterilization of milk filling environment, generally do not take aseptic production, such products require cold chain transportation, and shelf life short, usually within 3 days, but the fresh sense of strong, low packaging cost, cheap price. In addition, pasteurized milk is also available in roof type cartons and glass bottles.

- Q: How can the labels affixed to the bags be removed quickly?

- With the label supplies into the water immersion, after the label has been soaked, erase. This method is also applicable to metal and plastic tools, but it takes time.

- Q: What material should be used for transparent packing bags? How many cents do you want?

- PVC, English referred to as PVC (Polyvinyl chloride), is a vinyl chloride monomer (vinyl chloride monomer, referred to as VCM) in peroxide, such as azo compound initiator; or in light, under the action of heat polymerization by free radical reaction mechanism of polymerization of polymers. The vinyl chloride homopolymer and vinyl chloride copolymer are collectively referred to as vinyl chloride resins.

- Q: Can the meat with plastic packing bag be pressed directly with a pressure cooker?

- The plastic composite film (bag) products used in food packaging have 8 national and trade standards, and the main standards are divided into physical and mechanical performance indexes and sanitary performance indexes. The indexes of physical and mechanical properties are mainly tensile strength (or tensile strength), elongation, peel strength, heat resistance strength, Charpy impact energy, water vapor permeation amount and the amount of oxygen through the bag, bag, pressure resistance, heat resistance and dielectric performance drop, oil resistance, cold resistance, heat resistance etc.;

Send your message to us

Color Printed Stand Up Laminted Bag with Zipper for Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords