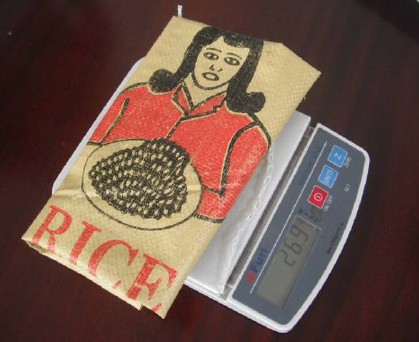

PP Woven Bag -100kg

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50000PCS pc

- Supply Capability:

- 5000T/MONTH pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PP Woven Bag for Rice 100kg:

This products is made by PP (Propene Polymer), it is used for Packing

rice,flour,sugar,sand,fertilizer and so on.Other products available: container bag, bulk bag, big bag, jumbo bag, woven fabric.

Specification of PP Woven Bag for Rice 100kg:

|

Material base fabric |

Fabric Weight |

CaCO3.Content |

size |

Yarn |

|

virgin PP |

40g/m2—200g/m2 AS customer’s requirements. |

0%-5% |

Width: from 30cm to 70cm Length: as per Customer’s requirements |

From 600 to 1,500D, as per your requirements

|

Color: white, black, yellow, multi-colors, as per your requirements

Warp x weft: 10 x 10, 12 x 12, 14 x 14, as per your requirements

Line density: 111tex

Top: to heat cut and/or hemmed

Bottom: single folded or double folded

Printing: on one side or both sides, in one color or multi-colors

Application of PP Woven bag for Ricec100kg:

The product are widely used in the storage and transportation of agricultural products, mineral products, chemical products, light industry products, etc

Packing of PP Woven Bag for Rice 100kg:

500pcs/bale,1000pcs/bale.with plastic bag outside ,then in container.

- Q:Plastic packing bag printing color

- A few colors, that is, a few colors, with several roll, one color needs a roll, and the more colors you have, the higher the cost of making the plate. Of course, the plate is calculated by area, the greater the size of your area, the higher the cost of making.

- Q:What ink is the food packing bag printed on?

- Because of this, benzene soluble chlorinated polypropylene ink has been gradually eliminated, and in Europe and other developed countries have gradually introduced or banned the use of benzene soluble chlorinated polypropylene ink laws and regulations.

- Q:What are the packaging forms of fresh milk?

- The main packaging forms of fresh milk are plastic bags, boxes and bottles. It is closely related to the way of sterilization of fresh milk

- Q:Antistatic packaging bag with chip

- Then anti-static shielding bag, black is conductive electrostatic material, regular 1000 ohm resistance, or is translucent gray, middle layer aluminized bag, play an important role in shielding

- Q:What material should be used for transparent packing bags? How many cents do you want?

- PVC products for packaging containers, mainly for a variety of film and film. PVC containers mainly produce mineral water, drinks and cosmetics bottles, as well as packaging for refined oils. The PVC film can be used in CO extrusion with other polymers to produce low cost laminates and transparent articles with good barrier properties. PVC film can also be used for stretch or heat shrink packaging, used for packaging mattresses, cloth, toys and industrial goods.

- Q:What are the types of composite packaging bags?

- Folding containerA large volume of transport package, the weight of more than 1 tons. The top of the container is usually equipped with metal hangers or rings, which is convenient for lifting and transporting of forklifts or cranes. When discharging, it is possible to open the discharge port at the bottom of the bag and unload the cargo conveniently. Suitable for shipment of granular or powdery articles.Container bags are usually made of polyester fibers such as polypropylene and polyethylene. Because the container loading and unloading of goods, transportation is very convenient, improve handling efficiency, in recent years made shoes soon.

- Q:What material is the packing bag for pure milk, please?

- W1l203 (station contact TA) should be food grade polyethylene, safe, easy to tear learn1986 (station contact TA), aluminum foil and polyethylene plastic film and paper interaction combined into polyethylene aluminum plastic composite packaging materials.

- Q:What about the use of plastic bags?

- Now all walks of life have the use of plastic packaging bags, only grades, such as the food market is the worst, supermarkets in general, and then to food packaging non-toxic environmentally friendly plastic bags. There are advantages and disadvantages. If it is a new material, the printing ink is also non-toxic. You can use it safely. If you use recycled materials, there is a foul smell. That's bad. What's more, we will bring plastic bags to the cooked food, it is best to buy from the supermarket, come back after the food will be taken out, to avoid food and plastic bags long-term exposure, chemical reaction products. That's bad for your health.

- Q:Express carton packaging, plastic packaging should be how to deal with?

- For those cartons, environmentalists have their own ways of using them. "The Jingdong loves to use plastic bags, and Amazon and its customers prefer cartons."." Some of the more orderly carton, you can keep as a storage box. You can use the marker pen to write the contents on the carton, then stack it on the bottom of the cupboard to improve the space utilization. For some cartons that cannot be used for the time being, use the tape on the carton to flatten the cartons.

- Q:What are the characteristics of a good package?

- This mainly refers to the packaging can perfectly protect and preserve the goods in the design of material selection, structure, can effectively cooperate with transportation storage loading and unloading circulation operation; enable consumers to use the goods, carrying and preservation is more convenient. In addition, whether the packaging material will cause pollution to the environment, and whether recycling is also very important. Packaging industry is a scientific and systematic project, and the packaging design must take into account the scientific aspects of each link, which also reflects the combination of art and science characteristics.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | Above US$ 3 Million |

| Main Markets | Eastern Asia, Africa, Domestic Market, South America, |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 80%-90% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Low; Average |

Send your message to us

PP Woven Bag -100kg

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50000PCS pc

- Supply Capability:

- 5000T/MONTH pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords