Color Printed Standup Pouch Laminated Packing Bag:

- Loading Port:

- China main port

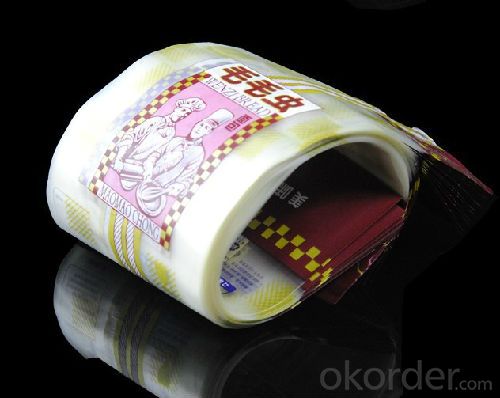

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Color Printed Standup Pouch Laminated Packing Bag:

Color Printed Standup Pouch Laminated Packing Bag are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Color Printed Standup Pouch Lamianted Packing Bag mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Color Printed Standup Pouch Laminated Packing Bag:

Excellent quality control

Experienced factory produced

SGS passed

3. Color Printed Standup Pouch Laminated Packing Bag Photos:

4. Color Printed Standup Pouch Laminated Packing Bag Specification:

1. Material: PE,LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Color Printed Standup Pouch Laminated Packing Bag:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Why a lot of the packaging bag surface is silver foil?

- Because candies are also considering moisture side so many sweets are wrapped in wax paper (because the wax paper can prevent water entering)For example, chocolate is a special kind of candy, its melting point is 36 degrees, it is very easy to get the temperature melting in the hand, so the reason is tin tin foil, the hands of the temperature can be very good to pass out to prevent the chocolate melts quickly.

- Q: What is the material for edible fungus stick packing bag?

- High pressure polypropylene bag, the bag has the characteristics of high temperature and high pressure, it can reach 120 degrees and not easily deformed. It is the first choice for factory cultivation.

- Q: What are the characteristics of a good package?

- According to the statistics of the foreign trade department, because of the backward packaging of export commodities, China has reduced the foreign exchange earnings by at least 10% per year. This shows that the good packaging design for the importance of national economic development.

- Q: What kind of material is the urea packing bag made of?

- Polypropylene (Polypropylene) is a semi crystalline thermoplastic (PP). With high impact resistance, strong mechanical properties, resistance to a variety of organic solvents and acid base corrosion.

- Q: What are the packaging forms of fresh milk?

- In recent years, aseptic composite plastic bags and aseptic plastic cups have developed rapidly. Among them, the composite plastic bag adopts multi layer composite process, and aseptic cup packing adopts a plurality of multi-layer plastic coextrusion sheets to realize the molding, sterilization, filling and sealing of the container. These forms of packaging ensure the quality of fresh milk while enriching the packaging of fresh milk.There is also a plastic bottle of the two sterilized milk, general shelf life in March or more.

- Q: What are the soft and hard sides of plastic bags? Material or process technology?

- The quality of plastic packaging is determined by both the material and the process. The material is no better than the good one. But the hardness of plastic is not a decisive factor in determining the quality of plastic, mainly to see what the use of what needs to keep products

- Q: How big is the vacuum pack 28*40cm?

- For custom vacuum bags, I would recommend a manufacturer who has customized experience in vacuum bags because it reduces your time cost and offers a lot of advice on packaging design and customization.

- Q: Is there any identification on the vacuum package?

- Laser inkjet printer, laser energy generator is the product surface engraved characters.

- Q: What's the difference between plastic packaging bags and clothing bags?

- Clothing bags and plastic bags are just a general term for packaged products. Bags can also be made in various forms, so the machines are different,

- Q: What can be easily removed from the words printed on plastic bags?

- A dye is a substance that makes certain colors adhere to the fiber and is not easily detached or discolored. The dye is usually dissolved in water, a part of the dye mordant dyes can adhere to the needs of the fiber. Dyes are substances that make fibers and other materials colored. They are divided into two main categories: natural and synthetic.

Send your message to us

Color Printed Standup Pouch Laminated Packing Bag:

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches