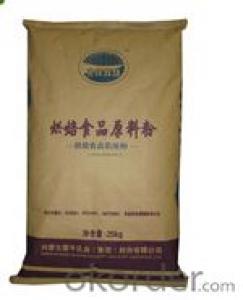

Environmental PP Woven Bag for Rice Packing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 80000 Pieces pc

- Supply Capability:

- 200000 Pieces per Day pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of Environmental PP Woven Bag For Rice Packing, Pp Woven Sack

1)100% new pp

2)Certificate ISO9001:2000

3)Customer design and logo available

Environmental PP Woven Bag For Rice Packing, Pp Woven Sack

Product name | PP woven bag for rice packing, pp woven sack |

Material | Porlypropylene (pp) woven virgin material |

Denier | From 400-1500D |

Color | Transparent, milk white, white, grey, red, blue, color etc. |

Weight/m2 | From 45-180 gsm (grams/m2) |

Printing | Offset printing, colorful printing. |

Usage | Packing rice, wheat, flour, sugar, paddy, grain, seeds, feed, corn, bean, patatos etc. |

TOP | Heat cut, cold cut, or fold hemmed sewn. |

Bottom | One fold or 2 folds, one line and 2 lines stiching, or paper heat sewing. |

Laminated | Bopp, Matt, Aluminum laminated, pearlized |

PE Liner | HDPE, LDPE liner insert |

Surface | Anti-slip, plain flat, glossy, matt |

Size | Width from 20-3750px. Length do as client request. |

Packing | 500pcs/bale, 800pcs/bale, 1000pcs/bale etc. |

UV treat | As per client request |

Handle |

D cut |

Gusset |

With or without |

Weave | 9X9,10X10,11X11,12X12,14X14 |

MOQ | Plain bag 2000pcs, colorful printing bag 8000pcs |

Leadtime | 10days after approval the samples |

- Q: Duck sauce made of pure aluminum foil vacuum packaging bag or transparent plastic?

- PET thin film / foil / nylon //PE thin film, it is best for the duck packaging, the longest period of hedging. Of course, there are some other place form, slightly reduce some costs, such as the PET// //PE aluminum foil film, but the effect was not as good as the former good bag, a bag to reduce the cost of not much, but the effect is significantly reduced, so it is recommended to use the former.

- Q: How do you determine the 210mm*300mm package and determine its version and length?

- Usually 1 meters, or 1 meters, 2 of the lengthWidth 300,3, leave 40 margin, roll on the design length of 940, version 420 weeks, diameter 133.75

- Q: What about the use of plastic bags?

- Now all walks of life have the use of plastic packaging bags, only grades, such as the food market is the worst, supermarkets in general, and then to food packaging non-toxic environmentally friendly plastic bags. There are advantages and disadvantages. If it is a new material, the printing ink is also non-toxic. You can use it safely. If you use recycled materials, there is a foul smell. That's bad. What's more, we will bring plastic bags to the cooked food, it is best to buy from the supermarket, come back after the food will be taken out, to avoid food and plastic bags long-term exposure, chemical reaction products. That's bad for your health.

- Q: What kind of material is the food packing bag in general?

- Custom food vacuum packaging bag, I recommend to have food vacuum packaging bag manufacturers customized experience, because it can reduce the cost and time for many of you, can give you a lot of packaging design and customized recommendations.

- Q: The difference between a vacuum and a vacuum in a food package

- And packaging techniques like inflatable bags are called inflatable.

- Q: Is there any identification on the vacuum package?

- DOD on demand machine (drop) for short, called ink jet printer. The working principle: the nozzle is made up of several high precision valves. When the word is sprayed, the corresponding valve is opened and closed quickly. The ink is ejected by the constant internal pressure, forming characters or graphics on the surface of the movement.

- Q: Dried fish vacuum packaging packing bag can not puncture

- Anti piercing vacuum packaging bags, first of all, choose the material of the bag to have toughness, followed by the thickness of the bag

- Q: How can the labels affixed to the bags be removed quickly?

- On the label with wind, a few minutes to unveil the label, the label will fall together with adhesive. Even at the stubborn stickers with traces of essential balm, and fingernails pull, usually can quickly clean up the traces.

- Q: What's the size of the 5 kg vacuum bag, please?

- Custom vacuum packing bag, I recommend to have experience in custom vacuum packaging bag manufacturers, because it can reduce the cost and time for many of you, can give you a lot of packaging design and customized recommendations.

- Q: What is the difference between package material PETAL and VMPET?

- Packing material:PETAL represents the PET film composite pure aluminum sheet material. Packaging industry called aluminum foil filmVMPET represents an aluminized PET film, which is a high temperature vacuum in which the high purity metal aluminum is uniformly applied to the plastic film. The packaging industry is called aluminized film.

1. Manufacturer Overview

| Location | Shandong ,China (Mainland) |

| Year Established | 2011 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Mid East Western Europe Southern Europe South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Environmental PP Woven Bag for Rice Packing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 80000 Pieces pc

- Supply Capability:

- 200000 Pieces per Day pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords