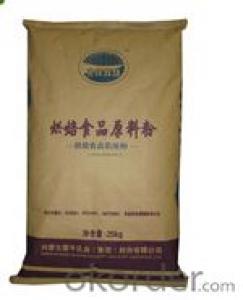

PP Woven Bag for Rice Packing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 80000 Pieces pc

- Supply Capability:

- 200000 Pieces per Day pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of PP Woven Bag For Rice Packing, Pp Woven Sack

1)100% new pp

2)Certificate ISO9001:2000

3)Customer design and logo available

PP Woven Bag For Rice Packing, Pp Woven Sack

Product name | PP woven bag for rice packing, pp woven sack |

Material | Porlypropylene (pp) woven virgin material |

Denier | From 400-1500D |

Color | Transparent, milk white, white, grey, red, blue, color etc. |

Weight/m2 | From 45-180 gsm (grams/m2) |

Printing | Offset printing, colorful printing. |

Usage | Packing rice, wheat, flour, sugar, paddy, grain, seeds, feed, corn, bean, patatos etc. |

TOP | Heat cut, cold cut, or fold hemmed sewn. |

Bottom | One fold or 2 folds, one line and 2 lines stiching, or paper heat sewing. |

Laminated | Bopp, Matt, Aluminum laminated, pearlized |

PE Liner | HDPE, LDPE liner insert |

Surface | Anti-slip, plain flat, glossy, matt |

Size | Width from 20-3750px. Length do as client request. |

Packing | 500pcs/bale, 800pcs/bale, 1000pcs/bale etc. |

UV treat | As per client request |

Handle |

D cut |

Gusset |

With or without |

Weave | 9X9,10X10,11X11,12X12,14X14 |

MOQ | Plain bag 2000pcs, colorful printing bag 8000pcs |

Leadtime | 10days after approval the samples |

- Q: The package specifications are 9 multiplied by 14 plus 3. How big is it?

- Now the standard of living has improved, basically vacuum packed bags. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q: What does "TM" mean in a food package?

- TM is common in foreign trademarks. It is the abbreviation of "trade mark" in English. "Trade mark" means "commercial mark" in Chinese, so "TM" means "trademark""

- Q: Can food wrap be heated in a microwave oven?

- There are two sides to consider1. sealed pockets are heated in a microwave oven, and the pressure in the bag is too large to explode! There are all the instructions on the microwave (as well as the eggs, and a hole). The microwave food I eat is also packed in plastic bags, but there's always room for gas2. material of packing bagGeneral contact with food bags, requirements are made of polyethylene (non-toxic, burning candles oil smell), general temperature 130 degrees, this pocket no problem (including the regular supermarket to buy plastic wrap and plastic wrap)However, there are a lot of cheap pocket (for example in the market and vest bag, supermarket cashier for plastic bags) are made of PVC, and can not contact with recycled plastic food; do not to mention (characteristics: cheap, taste, burning acrid smell)And, if it's made of polyethylene, don't heat it up with high oil food

- Q: How much is the 1 wire in the food packing bag printing industry?

- 1 wire =0.01 mm, refers to the thickness of the bag units!

- Q: What kind of material is the food packing bag in general?

- Are usually packaged in composite bags, composite materials, polyethylene (PE), polypropylene, nylon, polyester. These are the main membranes. The film is made of stretch film and blow film.

- Q: How big is the vacuum pack 28*40cm?

- Now the standard of living has improved, basically the vacuum bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q: Which kind of transparent vacuum packing bag 16 wire and 24 wire?

- The so-called silk is a unit, a trace of =0.01mm, from this point of view, the bag is thicker, the more difficult to leak, so the 24 wire than the 19 wire better.

- Q: Is there any identification on the vacuum package?

- Continue ink jet printer (continuous spraying machine), referred to as CIJ inkjet printer. The principle of operation is that the ink is ejected continuously through a single nozzle and is broken by crystal oscillation to form ink dots. After the ink point is charged and deflected at high pressure, the ink is scanned on the surface of the moving object. Such as Domino A100.

- Q: Printing solvent for food packing bag

- Determine the amount of water in the solvent by means of the principle of a different dissolution effect. Take the most transparent glass cylinder tube with 100ml toluene solution, take a small amount of analyte ester solvent such as toluene, evenly pour. When you just pour in toluene, carefully observe whether there is turbidity (milk white) phenomenon. If there is this phenomenon, the water content of the solvent is seriously exceeded, and the experience shows that when the moisture content exceeds 0.5%, the phenomenon is obvious. The water content test of benzene solvent can be carried out by extracting solvent from the long glass tube to observe whether there is delamination.

- Q: What's the difference between plastic packaging bags and clothing bags?

- From film making, printing to bag making, there's a big difference. The clothes bag you say is just a bag of bags. There are several kinds of clothes bags I have used, and each machine needs different machines

1. Manufacturer Overview

| Location | Shandong ,China (Mainland) |

| Year Established | 2011 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Mid East Western Europe Southern Europe South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Woven Bag for Rice Packing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 80000 Pieces pc

- Supply Capability:

- 200000 Pieces per Day pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches