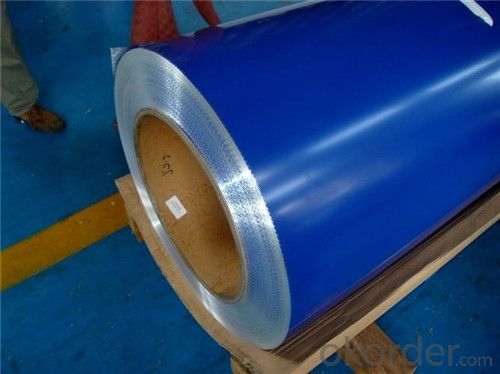

color coated galvanized Rolled steel coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Thickness : 0.14mm-1.2 mm

Width : 700mm-1250mm

Color : RAL code and as per customer

Zinc coating : 60-180g/m AZ 50-AZ275

Hardness : Normal soft/ Semi hard/ Full hard

Pre-Paint coating: 12-25um

Paint material: PE/PVDF

Color: Any color

Coil Inner Diameter: 508mm/610mm

Galvanized steel coil

Introduction:

The galvanized steel coil is made by cold rolled steel sheet, then trough chromated. unoiled, various spangles, hot dipped. The surface is coated by zinc or aluzinc. it is widely used as the raw materials of building. we have exported to midle east, africa, south america, ukraine for the good quality and best credit.

Specification:

Thickness : 0.14mm-0.8 mm

Width : 600mm-1250mm

Color : RAL code and as per customer

Zinc coating : 60-180g/m AZ 50-AZ275

Hardness : Normal soft/ Semi hard/ Full hard

Spangle: None spangle; Regular spangle; Big spangle

Surface treatment: Anti-finger/ None anti-finger

Coil Inner Diameter: 508mm/610mm

Add:

Topside: 5microns primer+ (10-20)microns polyester. Backside: 5-8microns primer epoxy.

The combining force between the galvanized or galvalume steel and the paint is very strong

The surface of Prepainted Steel Coil is normal or can be covered by film.

- Q: Ok, lately I've been taking to making things out of stainless steel chain mallie rings. The problem is that when i make a bracelet or something, the area around the fastener always looks pretty bad. I'm thinking to have a friend who also does chain mallie finish the weave all the way around. This would make it look good but make it impossible to remove.Are there any long term problems with stainless steel on skin? I know some metals will change the color of the skin or make the skin absorb some of the metal. Is this something to worry about with stainless steel?

- Stainless steel contains both nickel and chromium. These two alloys are responsible for most of contact dermatitis in people. Some of my co-workers making steel had such bad reactions to chromium that they had to quit their jobs. Their skin was always inflamed. People don't react to finished stainless steel the same way because the alloys are bonded tightly in the heat treating process. But if you are grinding it and getting the dust on your skin, you could get a contact dermatitis if you are sensitive. I don't think it would absorb into your blood stream or do any long term damage to your skin. If you do get a reaction, you would have to cease your exposure or in a worse case scenario risk getting a body wide reaction like my coworkers. I would not worry about any exposure making rings out of stainless steel. After all, stainless steel is used in sugical implants and most people are fine.

- Q: How are steel coils used in the manufacturing of industrial boilers?

- Steel coils are used in the manufacturing of industrial boilers as they are shaped and welded to form the boiler shell. The coils provide the necessary strength and durability to withstand high pressure and temperature conditions in the boiler. Additionally, the coils are often used to create the tubes and pipes that circulate the hot gases and water within the boiler, facilitating efficient heat transfer and steam generation.

- Q: pros and cons of stainless steel and carbon steel swords

- For display stainless is ok, no maintenance is required, for actual use carbon steel it the way to go, these blades will rust and need to be taken care of.

- Q: What are the different types of steel alloys used in coils?

- Coils commonly employ various types of steel alloys, each possessing unique properties and characteristics. Some frequently used types include: 1. Carbon Steel: As the most fundamental and widely utilized steel alloy in coils, it boasts low carbon content and renowned strength and durability. Carbon steel coils find extensive application in areas demanding high strength, such as automotive parts, construction materials, and machinery components. 2. Stainless Steel: Comprising an iron, chromium, and other element alloy, stainless steel coils exhibit exceptional resistance to corrosion, formidable strength, and heat resistance properties. They are typically employed in scenarios where shielding against corrosion and staining is pivotal, such as kitchen appliances, medical equipment, and transportation components. 3. Galvanized Steel: Galvanized steel coils are formed by coating regular carbon steel with a layer of zinc, furnishing excellent corrosion resistance and safeguarding the underlying steel from rust. Commonly utilized in outdoor settings like roofing, fencing, and automotive body parts. 4. Alloy Steel: Alloy steel coils are manufactured by incorporating diverse alloying elements like manganese, nickel, chromium, or molybdenum into carbon steel, thereby enhancing the steel's strength, hardness, and wear resistance. These coils frequently find application in industries necessitating high strength and toughness, such as machinery, tools, and construction equipment manufacturing. 5. Electrical Steel: Electrically specialized steel coils are designed explicitly for employment in electrical equipment like transformers and electric motors. These coils possess low electrical resistance and high magnetic permeability, facilitating efficient electricity conduction and magnetic field generation. Typically constructed from a silicon alloy, which enhances electrical and magnetic properties. In conclusion, the selection of a steel alloy for coils hinges upon the specific requirements of the given application, encompassing factors like strength, corrosion resistance, electrical conductivity, and heat resistance.

- Q: I have a steel plate 3' long x 2 wide x 3/16 thick. I have a 1/2 diameter hole with the center 3/4 from the end. Tensile strength is 38,000psi. A chain goes through the hole and is connected to a load. how does one determine how much tension the chain can have before it rips through the hole?

- Assuming that the chain can take the breaking load of the plate, the plate will fail at the area between the hole and the end, in double shear. The shear strength of the material should therefore be known for us to be able to calculate the breaking force. Approximately, the shear strength of steel is about 60% of the tensile strength. For ordinary mild steel the tensile strength is about 60,000 psi, not 38,000 psi. 38,000 psi is just about the yield point of mild steel. Using 60,000 psi tensile strength, the approximate shear strength of steel therefore is 36.000 psi. The net area between the hole and the end of the plate is: A = 3/16(3/4 - 1/4) = 0.09375 in^2 The force necessary to rip through the area which is also the tension on the chain is: T = 2 x 0.09375 x 36,000 = 6750 lbs

- Q: looking for a good pocket knife. i keep going through these 440 steel pocket knives with every day work usage. this will be my 4th. even when i use a whetstone they stay sharp for a short period of time but the edge does not last, 440 is too soft! what is a good steel to look for in a pocket knife? also what are some good brands. ive been using gerber and buck sofar. if you could recommend me a few mid/small sized knives i would greatly appreciate it!

- We hear it all the time and to be honest, it’s really, really hard to simply tell you what the ultimate pocket knife is. That’s because there are so many different knives on the market today and each one is suited to a different user and application. Of course there is a bunch of crap out there which we will endeavor to ensure you steer clear of but even after weeding those out you’re left with literally hundreds of choices from top quality manufacturers.

- Q: What are the different methods of cutting edge trimming for steel coils?

- There are several methods of cutting edge trimming for steel coils, including shearing, slitting, laser cutting, and plasma cutting. Shearing involves using a sharp blade to cut through the coil's edge, while slitting involves using multiple circular blades to make longitudinal cuts. Laser cutting uses a high-powered laser beam to melt and vaporize the material, producing a precise and clean cut. Plasma cutting involves using a high-temperature plasma arc to melt and cut through the steel. Each method has its advantages and is chosen based on factors such as the required precision, speed, and cost-effectiveness.

- Q: I remember my dad saying something about steel toed boots but I forgot =#92; I went and checked out all the stores and got a pair with good ankle support but they also have steel toes. Would this interfere with the shifter or anything? I figure if anything my dirt bike shoes have the steel toes too. Any opinion?

- I personally like to feel the shifter, and I've found that I can't feel the shifter as well through steel toed boots. Steel toed boots are designed to protect you in the event of something heavy dropping on your foot - which isn't very likely on a motorcycle. I have also found that in extreme cold that steel toed boots seem to act like a heat sink for your feet - non steel toed boots seem to stay just a little bit warmer. If you're a new rider, a very blunt toe (whether steel or not) can make getting your toes under the shifter a little more difficult, but with some practice and experience, you will get used to it. Honestly, I don't think it really makes all that much difference. All new riders have difficulty with the shifter, and it will take time for you to get used to it either way. I don't think the difference is really even worth going out and buying another set of boots, but yeah, if you were getting your first pair, I would tell you to look for a boot with a toe that is slender and tapered (vs. blunt), and non-steel.

- Q: How do steel coils contribute to the automotive aftermarket?

- The automotive aftermarket heavily relies on steel coils to manufacture a wide range of automotive parts and components. This secondary market deals with the sale of vehicle parts, accessories, and services after the initial purchase of the vehicle. Steel coils find their application in the production of several automotive aftermarket products, including springs, suspension components, chassis parts, and body panels. These coils are typically made from top-notch steel alloys that possess the desired characteristics of strength, durability, and performance. Springs are one of the primary uses of steel coils in the automotive aftermarket. These coiled springs play a crucial role in various automotive systems like suspension, brakes, and clutches. They provide the necessary support, stability, and shock absorption to ensure smooth and safe vehicle operation. Not only that, but steel coils also contribute to the manufacturing of chassis parts, which are vital for maintaining the vehicle's structural integrity and safety. Chassis parts made from steel coils include frame components, cross members, and reinforcement panels, which greatly enhance the overall stability and durability of the vehicle. Moreover, steel coils are extensively utilized in the production of body panels, such as doors, hoods, fenders, and roofs, which are commonly replaced or customized in the automotive aftermarket. These body panels, manufactured from steel coils, not only enhance the vehicle's aesthetics but also provide protection and resistance against impacts. In conclusion, steel coils play a critical role in the automotive aftermarket by facilitating the production of various parts and components necessary for vehicle repair, customization, and improvement. Their high strength, durability, and versatility make them an indispensable raw material, perfectly meeting the demanding requirements of the automotive industry.

- Q: How are steel coils used in the production of industrial shelving?

- Steel coils are used in the production of industrial shelving by being processed and shaped into various components such as shelves, frames, and brackets. These coils are cut, bent, and welded to create sturdy and durable structures that can support heavy loads in industrial settings. The strength and versatility of steel make it an ideal material for manufacturing industrial shelving, ensuring durability and longevity of the shelves.

Send your message to us

color coated galvanized Rolled steel coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords