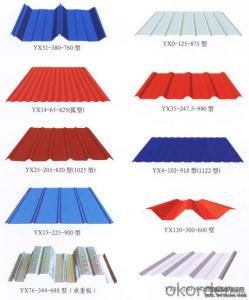

Color coated corrugated steel Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) AVAILABLE DESIGNATION OF (Prepainted galvanized steel coils) printed PPGI coils

Quality Q/BQB 440-2003 JIS G3312-1994 EN 10326-2004 ASTM A653-02a

EN 10327-2004 (BASE PLATE)

(BASE PLATE)

Commercial Steel TDC51D CGCC DX51D+Z/AZ CS Type A/B/C

Forming Steel (TSt01,TSt02,TSt03) CGCD1 FS Type A, Type B

Drawing TDC52D /TDC53D - DX52D+Z/AZ DDS TYPE A/C

Steel DX53D+Z/AZ

Structural TS280GD(TStE28) CGC400 S280D+Z/AZ SS275

Steel TS350GD(TStE34) CGC440 S350D+Z/AZ SS340 Class1

2) OUR SPECIFICATION OF (Prepainted galvanized steel coils) printed PPGI coils

Available Size:

Manufacturer Thickness Width Length of plate Inner diameter of coil

JIANGSU HUIYE STEEL SHEET CO.,LTD 0.2-1.2mm 800/914/1000/1200/1219/1250mm 1000-6000mm 508mm/610mm

Coated Mass OF (Prepainted galvanized steel coils) printed PPGI coils:

Base plate Available Coated Mass(g/m^2)

Galvanized Steel 80, 100, 120, 160, 180

Galvalume Steel 50, 70, 150

Available Painting OF (Prepainted galvanized steel coils) printed PPGI coils:

Category of Painting Item Code

Polyester PE

High-durability polyester HDP

Silicon modified polyesters SMP

Polyvinylidene fluoride PVDF

Easy-Cleaning —

Painting Thickness Top side: 20+5microns;

Bottom side: 5~7microns.

Color System Produce according to RAL Color System or as per buyer’s color sample.

Painting structure Top surface Bottom surface

Primer coating No coating 1/0

Primer coating Primer coating 1/1

Primer coating + Finish coating No coating 2/0

Primer coating + Finish coating Primer coating or single back coating 2/1

Primer coating + Finish coating Primer coating + Finish back coating 2/2

- Q: - I'm considering doing my physics coursework on the uses of Mild Steel in skyscrapers and construction, would this be right? Some sources tell me mild steel is too weak, others say it is fine

- Mild steel doesn't really mean anything, technically. In today's world all steel is mild steel unless it's high carbon or alloy, which are mostly tool steels. You'll need to study steel much deeper than that to accomplish any real physics work relating to steel.

- Q: That's my question, well that and:Steel Pick + Electric Guitar = Trashed Guitar?:D

- Uh. . . your guitar would be okay. . . except your strings wouldn't last long then nylon strings.

- Q: What is the maximum width of steel coils?

- The maximum width of steel coils can vary depending on the specific manufacturing processes and equipment capabilities, but it is typically around 72 inches (182.88 cm).

- Q: How are steel coils used in the production of metal cladding?

- Steel coils are used in the production of metal cladding as they are rolled into flat sheets and then formed into various shapes and profiles. These coils provide the raw material for manufacturing metal cladding panels, which are widely used in construction for their durability, weather resistance, and aesthetic appeal.

- Q: What is stainless steel 316, and what are its properties and uses?

- For machined aspects 416 cautioned. For welded aspects 316 is cautioned. besides the shown fact that 316 supplies a greater advantageous corrosion resistance. oftentimes the only benefit for 416 is machinability others than that 316 is greater advantageous

- Q: How are steel coils used in the production of industrial equipment?

- Steel coils are used in the production of industrial equipment as their versatile and durable nature makes them ideal for fabricating various components such as frames, structures, panels, and parts. These coils are processed and shaped into the required size and shape, allowing manufacturers to create sturdy and reliable equipment that can withstand heavy use and harsh environments.

- Q: I feel really stupid asking this question but i feel like a put metal/steel strings on my classical guitar how do you tell the difference?

- Nylon strings are made of nylon; steel strings are made of .... if you put steel strings on your nylon string (classical style) guitar, you will destroy it. The instrument cannot stand up under the tension required for the strings, they will not fit in the saddle properly, they will cut the nut, and your machine heads may break. ... now if you're asking about the three lowest strings, those are metal wound around nylon on a nylon string guitar.

- Q: bullets are normally made out of lead...are there bullets that are completely steel?? (not plated)

- Not for small arms and not for conventional artillery. In both cases, the projectile has to engage the rifling, which requires a material soft enough to upset into the grooves yet tough enough to stand up to the friction and the pressure. Small arms projectiles, even if the core is steel, must have at least a jacket of softer material, usually a copper alloy, to engage the rifling and seal the bore. Artillery projectiles for rifled weapons use driving bands of bronze or a similar alloy for the same reason. The Germans during World War II and probably some other resource-strapped armed services have used sintered iron bullets for handgun rounds such as 9mm Luger (I have a box, but have never shot one because of their value to collectors), but sintered iron is too fragile for the higher velocities and energies of rifle rounds. Several companies do make sporting bullets entirely of copper, which is a way to solve the problem conventional bullets sometimes have with shedding the jacket on impact with a game animal. You'll also find lots of foreign military ammo with cartridge cases made of mild steel. Russian and Chinese 7.62x39 often has these steel cases. You'll find tens of thousands of them rusting on the ground at rifle ranges all over the country. The bullets have a softer jacket, usually a copper alloy. Armor-piercing ammo has a core of hardened steel, but a jacket of copper alloy.

- Q: How are steel coils used in the construction of buildings?

- Steel coils are used in the construction of buildings primarily for their strength and durability. These coils are typically formed into beams, columns, and other structural components, providing a sturdy framework. Additionally, steel coils can be shaped into sheets or plates used for roofing, walls, and flooring, offering excellent resistance to weather and fire. Overall, steel coils play a crucial role in ensuring the stability and longevity of buildings.

- Q: How are steel coils used in the production of metal signage?

- Steel coils are used in the production of metal signage by being cut and shaped into the desired size and shape for the signs. The coils provide a sturdy and durable base material for the signs, ensuring their longevity and ability to withstand various weather conditions.

Send your message to us

Color coated corrugated steel Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords