Aluminum Coil Printing - Color Coated Aluminium Coil PVDF Painting for Outer Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coated Aluminium Coil PVDF painting for Outer Doors

Material | Alloy Aluminum 1XXX,3XXX,5XXX or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating,PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Color Coated Aluminium Coil PVDF painting for Outer Doors

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Aluminium Coil PVDF painting for Outer Doors

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

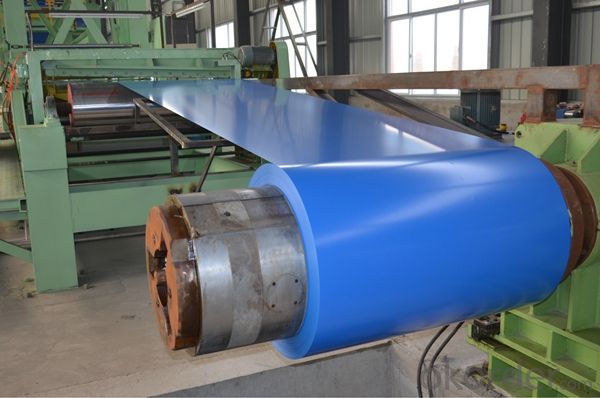

5. Image of Color Coated Aluminium Coil PVDF painting for Outer Doors

6. Package and shipping of Color Coated Aluminium Coil PVDF painting for Outer Doors

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be painted or coated with different colors?

- Yes, aluminum coils can be painted or coated with different colors.

- Q: Is it possible to recycle aluminum coils?

- <p>Yes, aluminum coil can be recycled. Recycling aluminum is a highly efficient and environmentally friendly process. It requires only 5% of the energy needed to produce new aluminum from raw materials. Recycled aluminum coils can be used to manufacture new aluminum products, reducing waste and conserving resources. The recycling process typically involves melting the aluminum, which can then be reshaped into new coils or other forms. This makes aluminum one of the most recycled materials in the world.</p>

- Q: Can aluminum coils be used in the production of household appliances?

- Household appliances can indeed utilize aluminum coils in their production. Aluminum, a material known for its lightweight and durable nature, boasts exceptional thermal conductivity, rendering it highly suitable for various appliance applications. Refrigerators, air conditioners, and heat pumps, for instance, greatly benefit from the utilization of aluminum coils. These coils are commonly employed in the condenser and evaporator coils of such appliances, efficiently facilitating heat transfer. Moreover, the corrosion resistance of aluminum coils is pivotal in ensuring the longevity and optimal performance of household appliances. Consequently, owing to their advantageous properties and benefits, aluminum coils remain a favored option in the production of household appliances.

- Q: How are aluminum coils protected against chemical exposure?

- Aluminum coils are protected against chemical exposure through a variety of methods. One common method is the application of a protective coating or finish on the surface of the coils. This coating acts as a barrier between the aluminum and any potentially harmful chemicals, preventing direct contact and corrosion. Another method is the use of anodization, which involves electrolytically treating the aluminum surface to create a layer of oxide. This oxide layer provides excellent resistance against chemical exposure and enhances the overall durability of the coils. Anodized aluminum coils are widely used in industries where chemical resistance is crucial, such as in construction, automotive, and aerospace applications. Furthermore, aluminum coils can be protected by using alloys that are specifically designed to resist chemical corrosion. These alloys contain additional elements, such as copper or magnesium, which enhance the aluminum's resistance to chemical attack. By carefully selecting the appropriate alloy composition, manufacturers can ensure that the aluminum coils are better able to withstand chemical exposure. Overall, the protection of aluminum coils against chemical exposure involves a combination of protective coatings, anodization, and the use of corrosion-resistant alloys. These measures help to extend the lifespan of the coils and maintain their performance even in harsh chemical environments.

- Q: Are there any limitations on the bending or shaping of aluminum coils?

- Yes, there are limitations on the bending or shaping of aluminum coils. Aluminum is a relatively soft and malleable metal, which makes it suitable for bending and shaping. However, it does have some limitations. Firstly, the thickness of the aluminum coil can affect its bendability. Thicker aluminum coils are generally more difficult to bend or shape compared to thinner ones. This is due to the increased resistance to deformation in thicker materials. Secondly, the temper or hardness of the aluminum coil can also impact its bendability. Different tempers, such as soft, half-hard, or hard, have varying degrees of malleability. Soft tempers are easier to bend, while harder tempers require more force and may be prone to cracking or breaking during bending. Additionally, the design and complexity of the desired bend or shape can also impose limitations. Sharp bends or complex shapes may cause the aluminum coil to crack or deform, especially if it is not properly supported or if the bending radius is too small. Lastly, the presence of any impurities, defects, or alloying elements in the aluminum coil can affect its bendability. These factors can lead to inconsistencies in the material's mechanical properties, making it more prone to cracking or breaking during bending or shaping. Therefore, while aluminum coils offer flexibility for bending and shaping, it is important to consider the thickness, temper, design, and quality of the material to ensure successful and safe manipulation.

- Q: What is the coefficient of thermal expansion of aluminum coils?

- The coefficient of thermal expansion of aluminum coils is typically around 23 x 10^-6 per degree Celsius.

- Q: and alsoHow many grams of the decay product will have formed after 8 days go by?The decay product is the new isotope created as a result of the positron decay of aluminum-24.In class my teacher didn't explain this completely but there's a question on the homework that me and even my mom (another teacher) can't find the answer to.

- so it 6000/ (2*8*24*60*60) 0.00434027778 grams have you heard of the internet an unless your mom is a chem teacher it doesnt mean much

- Q: Will the aluminum braking surface dissipate heat evenly allowing for fast stops from fast descents or will I have to still pulsate braking to reduce heat build up in the tires and tubes?

- Aluminum is tried and true, basalt seems like a gimmick. Aluminum's light, it's sought after over steel, which is cheaper and heavier and stronger. No basalt, no need.

- Q: How are aluminum coils annealed?

- Aluminum coils are annealed through a process called solution annealing. This involves heating the coils to a specific temperature and then rapidly cooling them. The purpose of annealing is to soften the aluminum, increase its ductility, and relieve any internal stresses.

- Q: Can aluminum coils be used in the production of heat sinks?

- Indeed, the utilization of aluminum coils is applicable in the manufacturing process of heat sinks. Aluminum, owing to its remarkable thermal conductivity and affordability, enjoys widespread usage as a material for heat sinks. These heat sinks are efficiently employed in the dissipation of heat emanated from electronic components like processors, power transistors, and LED lights. The coils can be fabricated into diverse forms and dimensions to fulfill particular heat dissipation prerequisites. Furthermore, aluminum possesses the advantages of being lightweight, resistant to corrosion, and readily accessible, rendering it an optimal selection for the production of heat sinks.

Send your message to us

Aluminum Coil Printing - Color Coated Aluminium Coil PVDF Painting for Outer Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords