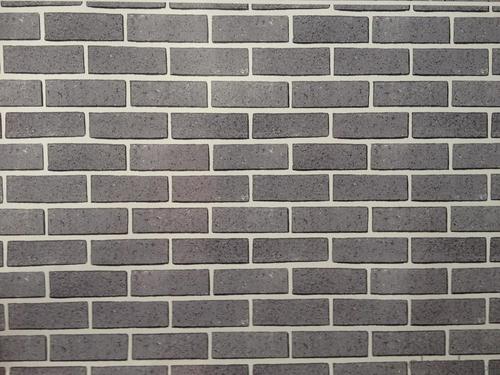

color bond surface coating steel plate--XY007

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Color bond surface coating steel plate :

2.more than ten years experiences, the products are sold to the domestic city and some international cities we strivc to develop production of color coating steel plate the plating (aluminum )

zinc steel. Coil cheickness between 0.6mm and 1.5mm and the width from 600mm to 1250mm and a variety of high durability of color coating steel plate.

3.The company has multiple layer patterns for customers to choose The company provides products deep processing services ,meet the various needs of customers on board specifications All of out products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world if you ate interested in any of our products or would like to discuss a custom order please feel free to contact us we are looking forward to forming successful business relationships with new clients around the world in the near future.

4.We can design the color and thickness according to customers' requirements. The delivery time is only 30 day after you confirm the order.

- Q: Are the steel sheets available in different grades?

- Yes, steel sheets are available in different grades.

- Q: Are steel sheets suitable for outdoor applications?

- Yes, steel sheets are suitable for outdoor applications. Steel is highly durable, weather-resistant, and can withstand harsh environmental conditions, making it an excellent choice for outdoor usage.

- Q: Are steel sheets suitable for food processing facilities?

- Yes, steel sheets are suitable for food processing facilities. Steel is a durable and hygienic material that is resistant to corrosion, easy to clean, and can withstand high temperatures. It is commonly used in food processing facilities to ensure food safety and maintain a clean and sanitary environment.

- Q: What are the different types of steel sheet finishes for decorative purposes?

- Some different types of steel sheet finishes for decorative purposes include brushed, mirror, embossed, and textured finishes.

- Q: What is the difference between a satin and mirror finish steel sheet?

- The appearance and level of reflectivity distinguish a satin finish steel sheet from a mirror finish steel sheet. A satin finish steel sheet displays a sleek, non-glossy appearance with a minimal level of reflectivity. Achieved through the use of abrasive materials, it creates a brushed or textured surface. This finish is often favored for its contemporary and subtle aesthetic. Satin finish steel sheets find common usage in architectural and interior design applications, such as kitchen appliances, countertops, and wall panels. On the contrary, a mirror finish steel sheet exhibits an immensely reflective surface that closely resembles a mirror. Achieved by polishing the steel sheet to a high gloss using fine abrasives and buffing compounds, this finish boasts an intense shine and exceptional clarity. It reflects light remarkably, resulting in a glamorous and opulent appearance. Mirror finish steel sheets are commonly employed in decorative applications, including automotive trim, jewelry, and ornamental architectural elements. To summarize, the primary distinction between a satin and mirror finish steel sheet resides in their appearance and level of reflectivity. Satin finish offers a smooth, matte appearance with minimal reflectivity, while mirror finish provides an incredibly reflective, mirror-like surface.

- Q: What is the difference between a corrugated and flat steel sheet?

- The main difference between a corrugated and flat steel sheet lies in their physical structure. A corrugated steel sheet is characterized by its ridges and valleys, which give it a wavy or ribbed appearance. This design provides increased strength and durability, making it suitable for applications that require structural integrity, such as roofing and siding. On the other hand, a flat steel sheet lacks these ridges and valleys, offering a smooth and even surface. Flat sheets are commonly used in applications where a sleek and uniform look is desired, such as automotive bodies, appliances, and metal fabrication projects.

- Q: Can steel sheets withstand extreme weather conditions?

- Yes, steel sheets are designed to withstand extreme weather conditions due to their inherent strength, durability, and resistance to corrosion. They can withstand heavy rain, snow, high winds, and even hailstorms without getting damaged. Additionally, steel sheets are also fire-resistant, making them a reliable choice for various applications in extreme weather environments.

- Q: Are steel sheets suitable for food storage applications?

- Steel sheets are indeed suitable for food storage applications. Steel is a highly durable and versatile material that is resistant to corrosion, making it an excellent choice for storing food. Steel sheets provide a hygienic and safe environment for food, as they are non-porous and do not absorb odors or flavors. They also offer protection against contaminants and pests, ensuring the integrity and freshness of the stored food. Additionally, steel sheets are easy to clean and maintain, making them ideal for food storage facilities, restaurants, and any other application where food safety is a priority.

- Q: What are the different alloying elements used in steel sheets?

- There are several alloying elements used in steel sheets to enhance their properties and performance. Some of the commonly used alloying elements include: 1. Carbon: The most important alloying element in steel, carbon provides strength and hardness to the material. It also improves the steel's ability to be heat-treated, making it suitable for various applications. 2. Manganese: Manganese is commonly added to steel sheets to improve their mechanical properties, such as strength and toughness. It also helps in reducing the brittleness of the steel. 3. Chromium: Chromium is added to steel sheets to enhance their corrosion resistance. It forms a thin protective layer on the surface of the steel, preventing it from rusting or corroding easily. 4. Nickel: Nickel is often used in steel sheets to improve their toughness and resistance to impact. It also enhances the steel's ability to withstand extreme temperatures, making it suitable for high-temperature applications. 5. Silicon: Silicon is commonly added to steel sheets to improve their strength and hardness. It also helps in deoxidizing the steel during the manufacturing process. 6. Vanadium: Vanadium is used as an alloying element in steel sheets to improve their strength, toughness, and heat resistance. It also helps in refining the grain structure of the steel, making it more uniform and fine. 7. Copper: Copper is added to steel sheets to improve their corrosion resistance and thermal conductivity. It also enhances the steel's ability to be welded and brazed. 8. Tungsten: Tungsten is used as an alloying element in steel sheets to improve their hardness, strength, and wear resistance. It is often added in small amounts to enhance the steel's cutting and drilling capabilities. These are just a few examples of the alloying elements commonly used in steel sheets. The choice of alloying elements depends on the specific requirements of the application and the desired properties of the steel. Different combinations and concentrations of these elements can be used to achieve a wide range of characteristics in steel sheets.

- Q: What is the average wind load capacity of steel sheets?

- The average wind load capacity of steel sheets can vary depending on various factors such as the thickness of the sheet, the type of steel used, and the specific design and installation of the structure. However, steel sheets are known for their high strength and durability, making them capable of withstanding significant wind loads. Typically, steel sheets used for roofing or cladding applications are designed to meet specific wind load requirements based on regional building codes and standards. These standards take into account factors such as the geographical location, building height, exposure category, and wind speed. To determine the wind load capacity of steel sheets, engineers and architects use calculations and simulations to analyze the forces exerted by the wind on the structure. They consider factors such as wind pressure, building orientation, surface area, and the shape and profile of the steel sheets. In summary, the average wind load capacity of steel sheets cannot be generalized as it varies based on several factors. It is crucial to consult with a structural engineer or building professional to determine the appropriate wind load capacity requirements for a specific steel sheet application.

Send your message to us

color bond surface coating steel plate--XY007

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords