Cold Work JIS DC53 Mould Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

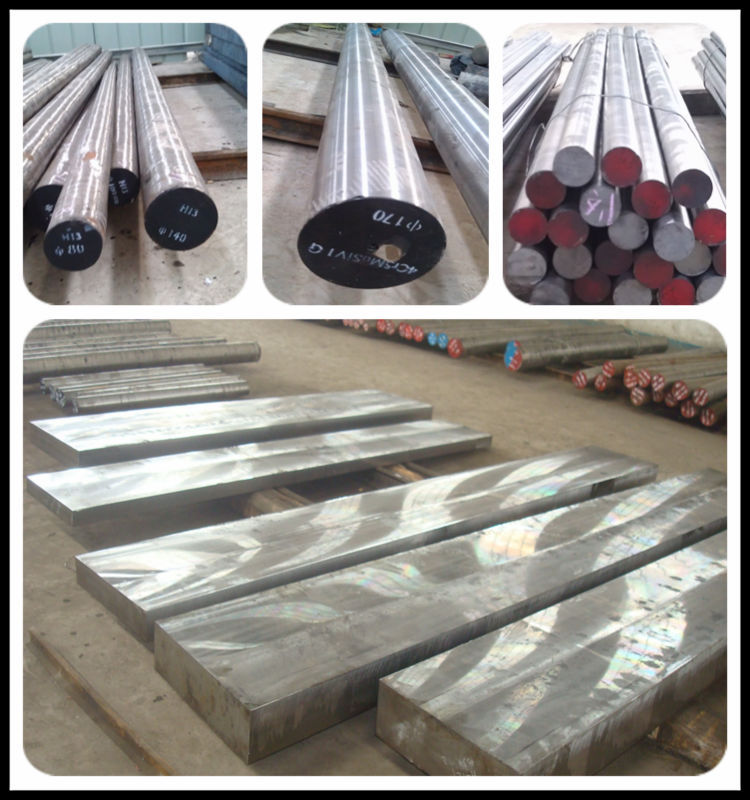

Cold Work JIS DC53 Mould Steel Round Bar

Specification :

| Size | round | Dia 18mm~220mm |

| flat | Thickness 6mm-400mm | |

| Width 60mm-610mm | ||

| Technique | Cold Drawn/Cold Pilfered/Cold Rolled/Hot Rolled/forge- | |

| Process | EAF+LF+VD+ Forged/Hot rolled + Heat Treatment (Annealed,A Normalized, Q+T) | |

| Heat treatment | Normalized ; Annealed ; Quenched ; tempered | |

| Surface Condition | Black surface ; Grinded ; Machined;Turned | |

| Inspection | 100% Ultrasonic according to the test standards:SEP1921-84,CLASS C/c or D/d | |

| Payment Terms | T/T;L/C | |

| Trade Terms | FOB;CIF,CFR | |

| Packing | Standard seaworthy packing or as customer required | |

| Application | various large-sized mirror plastic mould, precision plastic mould, like: cars accessies, home appliances, electronic equipment plastic mould | |

Introduction:

DC53 is a general purpose cold work tool steel with exceptional Toughness, Wear Resistance, Compressive Strength and Temper Resistance.

These properties are obtained through its chemistry as well as its unique manufacturing processes of ladle refinement, vacuum degassing and forging methods. DC53 also has excellent machining characteristics and is well suited as a sub-straight for PVD surface treatments. DC53 can also be hot process CVD and TD (Thermal Diffusion) coated however post heat treat is generally recommended.

Chemical Composition :

| Steel Grade | C | Si | Mn | Cr | P | S | Co |

| 9SiCr | 0.85-0.95 | 1.2-1.6 | 0.3-0.6 | 0.95-1.25 | ≤0.03 | ≤0.03 | ≤1 |

Applications include:

Punches & dies

Draw & forum dies

Shear blades

Shredder knives

Thread & form rolls

Cold heading dies

Mill rolls & slitters

Product list

| GB/T | ASTM | JIS | EN ISO | DIN | NFA | BS |

| 3Cr2W8V | H21 | SKD5 | X30WCrV9-3 | 1.2581 | Z30WCV9 | BH21 |

| 4Cr5MoSiV1 | H13 | SKD61 | X40CrMoV5-1 | 1.2344 | Z40CDV5 | BH13 |

| Cr12 | D3 | SKD1 | X210Cr12 | 1.208 | Z700C12 | BD3 |

| Cr12MoV | D5 | SKD11 | X165CrMoV12 | 1.2601 | ||

| Cr12Mo1V1 | D2 | SKD11 | X155CrVMo121 | 1.2379 | Z160CDV12 | BD2 |

| Cr8Mo1VSi | DC53 | - | - | - | - | |

| 9SiCr | ||||||

| 9Mn2V | O2 | 90MnCrV8 | 1.2842 | |||

| CrWMn | SKS31 | |||||

| 9CrWMn | O1 | SKS3 | 95MnWCr5 | |||

| 5CrNiMo | L6 | SKT4 | 55NiCrMoV7 | |||

| 3Cr2Mo | P20 | 35CrMo7 | 1.2311 | |||

| 3Cr2NiMo | P20+Ni | 40CrMnNiMo8-6-4 | 1.2738 |

Products:

Packaging :

By Seaworthy packing

Shipping :

within 7-30 days after payment

- Q: What are the common sizes of steel round bars?

- The specific application and industry standards determine the varying common sizes of steel round bars. Depending on these factors, the sizes can range from 1/4 inch to 24 inches in diameter. The availability of these sizes is often in increments of 1/8 inch or 1/4 inch. It is worth noting that the sizes may differ based on the country or region. Moreover, metric sizes are also an option, with diameters generally ranging from 6mm to 600mm. The extensive selection of steel round bar sizes enables a wide range of applications across different industries.

- Q: Can steel round bars be used in the manufacturing of tools?

- Yes, steel round bars can be used in the manufacturing of tools. Steel round bars are commonly used in tool manufacturing due to their high strength, durability, and versatility. They provide the necessary structural integrity and toughness required for various tools, such as wrenches, hammers, chisels, and screwdrivers. The round shape of the bar allows for easy machining and shaping into different tool components. Additionally, steel round bars can be heat treated to enhance their hardness and wear resistance, making them suitable for heavy-duty and high-performance tool applications.

- Q: Can steel round bars be anodized?

- No, steel round bars cannot be anodized. Anodizing is a process that is specific to aluminum and its alloys.

- Q: Can steel round bars be used for hydraulic applications?

- Yes, steel round bars can be used for hydraulic applications. Steel is known for its strength and durability, making it a suitable material for hydraulic systems that require high pressure and heavy loads. Steel round bars can be used to manufacture various hydraulic components such as cylinders, pistons, shafts, and valves. The hardness and corrosion resistance of steel also make it a reliable choice for hydraulic applications where the fluid may contain contaminants or have high temperatures. However, it is important to consider the specific requirements of the hydraulic application and select the appropriate grade and type of steel round bars to ensure optimal performance and longevity.

- Q: Can steel round bars be used in the production of packaging equipment?

- Yes, steel round bars can be used in the production of packaging equipment. Steel round bars are commonly used in the manufacturing industry due to their high strength and durability. They can be used to construct various components such as shafts, rods, or rollers, which are essential for the proper functioning of packaging equipment. Steel round bars also offer excellent resistance to wear and tear, making them ideal for heavy-duty applications in the packaging industry.

- Q: What are the advantages of using creep-resistant steel round bars?

- Using creep-resistant steel round bars in various applications has several advantages. Firstly, these bars offer exceptional resistance to high temperatures and prolonged stress exposure, making them ideal for high temperature environments such as power plants, boilers, and engines. Their ability to maintain their mechanical properties at elevated temperatures is a key advantage. Secondly, these round bars possess superior creep strength, allowing them to endure constant stress over extended periods without deformation or failure. This is particularly crucial in applications where components are subjected to continuous stress, such as pressure vessels or structural machinery. The high creep strength ensures the longevity and reliability of these components. Additionally, creep-resistant steel round bars exhibit excellent corrosion resistance. They are often alloyed with elements like chromium, molybdenum, or nickel, enhancing their ability to resist corrosion in harsh environments. This makes them suitable for industries like oil and gas, chemical processing, and marine applications where corrosion is a significant concern. Furthermore, these round bars possess favorable weldability, facilitating easy fabrication and assembly. They can be welded to other components without compromising their mechanical properties, making them versatile and cost-effective for construction projects. Moreover, these round bars offer dimensional stability and high hardness, guaranteeing that components maintain their shape and mechanical properties even under extreme conditions. This characteristic makes them suitable for applications requiring precision and accuracy, such as aerospace and automotive industries. In conclusion, the advantages of using creep-resistant steel round bars include their ability to withstand high temperatures, superior creep strength, corrosion resistance, weldability, dimensional stability, and high hardness. These advantages make them the preferred choice for various industries where reliability, longevity, and performance under harsh conditions are essential considerations.

- Q: How do steel round bars compare to stainless steel round bars?

- Steel round bars and stainless steel round bars differ in their composition, making them suitable for various applications. The composition of steel mainly consists of iron with small amounts of carbon and other elements, whereas stainless steel is an alloy composed of iron, chromium, and often other elements like nickel or molybdenum. This unique composition gives stainless steel its distinctive properties, such as corrosion resistance. Both steel and stainless steel round bars can be manufactured to have high tensile strength. However, stainless steel generally has higher tensile strength compared to regular steel, making it more suitable for applications requiring additional strength and durability. Another significant difference lies in their resistance to corrosion. Stainless steel round bars have excellent corrosion resistance due to the presence of chromium in their composition, making them ideal for applications exposed to moisture, chemicals, or other corrosive environments. On the other hand, steel round bars are more prone to rust and corrosion and may need additional protective coatings in such environments. In terms of cost, steel round bars are generally more affordable compared to stainless steel round bars. The higher cost of stainless steel is attributed to its unique properties and the additional alloying elements required in its production. Both steel and stainless steel round bars have advantages and specific applications. Steel round bars are commonly used in construction, manufacturing, and general-purpose applications where corrosion resistance is not a primary concern. In contrast, stainless steel round bars find extensive use in industries such as food processing, chemical processing, medical equipment, and marine applications where corrosion resistance is crucial. In conclusion, the choice between steel round bars and stainless steel round bars depends on the specific requirements of the application. Steel round bars are more cost-effective but may require additional corrosion protection, while stainless steel round bars offer superior corrosion resistance and strength.

- Q: Can steel round bars be used in the manufacturing of pumps?

- Yes, steel round bars can be used in the manufacturing of pumps. Steel round bars are commonly used in various industries for their strength, durability, and versatility. In pump manufacturing, steel round bars are often used as shafts or rotors due to their ability to withstand high pressure and rotational forces. The steel round bars can be machined, forged, or heat-treated to meet the specific requirements of the pump design. Additionally, steel round bars provide excellent corrosion resistance, making them suitable for pumps used in various environments. Overall, steel round bars are a reliable and commonly used material in pump manufacturing.

- Q: Can steel round bars be used for making automotive suspension systems?

- Yes, steel round bars can be used for making automotive suspension systems. Steel round bars are commonly used in the manufacturing of suspension components such as control arms, sway bars, and torsion bars due to their high strength, durability, and ability to withstand heavy loads and vibrations.

- Q: Can steel round bars be used in the oilfield equipment industry?

- Yes, steel round bars can be used in the oilfield equipment industry. Steel round bars are commonly used in the oilfield industry due to their high strength, durability, and resistance to corrosion. They are used to manufacture various components and equipment such as drill collars, drill bits, valves, and pump shafts. The use of steel round bars ensures that the equipment can withstand the harsh conditions and extreme pressures encountered in oilfield operations. Additionally, steel round bars can be easily welded and machined to meet specific requirements, making them a versatile choice for the oilfield industry.

Send your message to us

Cold Work JIS DC53 Mould Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords