Cold Rolled Steel Coils 2B Finish Grade 304 Grade 316 Grade 430

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

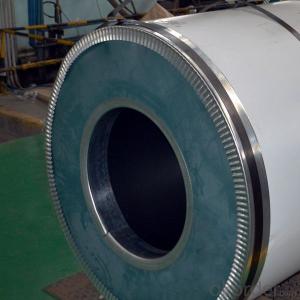

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

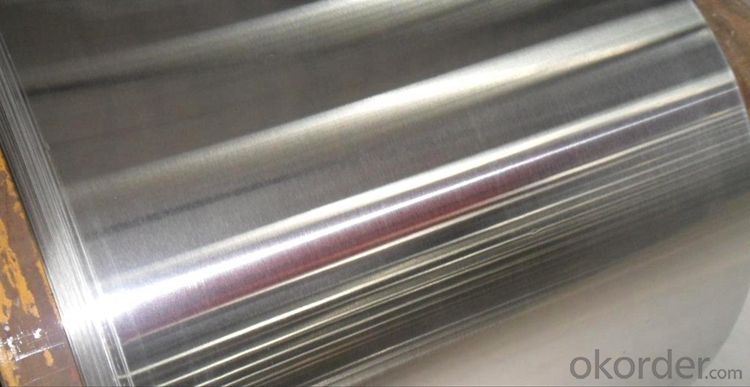

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: Can stainless steel sheets be used for elevator floors?

- Indeed, elevator floors can indeed make use of stainless steel sheets. Known for its durability and resistance to corrosion, stainless steel is widely employed in numerous fields, including elevator interiors. Elevator floors adorned with stainless steel sheets exude a sophisticated and contemporary aesthetic, all while effectively withstanding scratches, blemishes, and impacts. Moreover, stainless steel's effortless cleanliness and maintenance make it an ideal selection for elevator floors that endure substantial foot traffic.

- Q: Can stainless steel sheets be used for decorative backsplashes?

- Yes, stainless steel sheets can be used for decorative backsplashes. Their sleek and modern appearance, durability, and resistance to stains and corrosion make them a popular choice for adding a stylish and functional element to kitchens or other spaces.

- Q: Stainless steel sheet welding method, thickness of 0.5mm

- Common welding method: pulse DC TIG welding.

- Q: How do you prevent galling on stainless steel sheets?

- To prevent galling on stainless steel sheets, it is important to use lubricants or anti-seize compounds during the manufacturing or assembly process. This helps reduce friction and surface adhesion, minimizing the risk of galling. Additionally, using proper cutting tools and techniques, such as slow speeds and low feed rates, can also help prevent galling.

- Q: Can stainless steel sheets be used in food processing?

- Yes, stainless steel sheets can be used in food processing. Stainless steel is a common material used in the food industry due to its many beneficial properties. It is highly resistant to corrosion, which is crucial in food processing environments where frequent contact with water, chemicals, and food is expected. Stainless steel sheets are also non-reactive, meaning they do not interact with food or affect its taste, making it a safe choice for food processing equipment. Additionally, stainless steel is easy to clean and maintain, making it suitable for maintaining high levels of hygiene required in food processing facilities. Its durability and strength also ensure that it can withstand the rigorous demands of food processing operations. Overall, stainless steel sheets are a preferred material in the food industry due to their suitability for food processing applications.

- Q: What are the applications of stainless steel sheets?

- Stainless steel sheets have a wide range of applications due to their unique properties. They are commonly used in construction for roofing, cladding, and facades as they offer durability, corrosion resistance, and aesthetic appeal. In the automotive industry, stainless steel sheets are utilized for manufacturing various components, including exhaust systems, grilles, and body panels. They are also employed in the food processing and pharmaceutical industries for their hygienic properties. Additionally, stainless steel sheets find applications in kitchen appliances, chemical plants, marine equipment, and medical instruments, among others.

- Q: Can stainless steel sheets be used for wall paneling?

- Yes, stainless steel sheets can be used for wall paneling. Stainless steel is a versatile material that is known for its durability, resistance to corrosion, and aesthetic appeal. It is commonly used in various applications, including wall paneling in both residential and commercial settings. Stainless steel sheets can be easily installed as wall panels, providing a modern and sleek look to the space. Additionally, stainless steel is easy to clean and maintain, making it a practical choice for wall paneling in areas that require regular cleaning, such as kitchens and bathrooms. Overall, stainless steel sheets are a great option for wall paneling due to their durability, aesthetic appeal, and ease of maintenance.

- Q: What are the different types of stainless steel sheet surface finishes available?

- Some of the different types of stainless steel sheet surface finishes available include: 1. No.1 Finish: This is a rough, dull surface finish with visible grain lines. 2. No.2B Finish: It has a smooth, bright finish that is commonly used for appliances and architectural applications. 3. No.4 Finish: This finish has a brushed appearance with fine grain lines and is often used in decorative applications. 4. No.8 Mirror Finish: It provides a highly reflective surface that is used for decorative purposes. 5. Satin Finish: It has a smooth, silky appearance with low reflectivity and is commonly used in architectural and decorative applications. 6. Brushed Finish: This finish has a consistent linear grain pattern created by brushing the surface with abrasive materials. 7. Embossed Finish: It features raised patterns or textures on the surface, providing a decorative and tactile effect. 8. Bead Blast Finish: It creates a uniform, matte surface texture by blasting stainless steel sheets with fine glass beads. 9. Etched Finish: This finish involves chemically etching the surface to create patterns or designs. 10. Colored Finish: Stainless steel sheets can be coated or treated to achieve various colors and finishes, allowing for customization and aesthetic appeal.

- Q: Can stainless steel sheets be used for pressure vessels?

- Yes, stainless steel sheets can be used for pressure vessels. Stainless steel offers excellent strength, corrosion resistance, and durability, making it a suitable material for containing high-pressure gases or liquids. Additionally, stainless steel can withstand different temperatures and is easy to clean, making it a popular choice for pressure vessel applications in industries such as chemical processing, oil and gas, and food processing.

- Q: Can stainless steel sheets be used for architectural canopies?

- Yes, stainless steel sheets can be used for architectural canopies. Stainless steel is a versatile material that offers several benefits in architectural applications, including canopies. Firstly, stainless steel is highly durable and resistant to corrosion, making it suitable for outdoor installations. This ensures that the canopy will withstand harsh weather conditions and maintain its appearance over time. Additionally, stainless steel has a sleek and modern aesthetic that can enhance the overall design of the canopy. It can be polished to a mirror-like finish or brushed to create a unique texture, providing architects with various options to achieve their desired look. Stainless steel sheets are also available in different thicknesses, allowing for customization based on the specific requirements of the canopy. This flexibility ensures that the material can support the weight of the structure and any additional elements, such as lighting or signage. Moreover, stainless steel is a sustainable choice for architectural canopies as it is fully recyclable. This aligns with the growing demand for environmentally-friendly construction materials and practices. In summary, stainless steel sheets are a suitable and popular choice for architectural canopies due to their durability, aesthetic appeal, flexibility, and sustainability.

Send your message to us

Cold Rolled Steel Coils 2B Finish Grade 304 Grade 316 Grade 430

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords