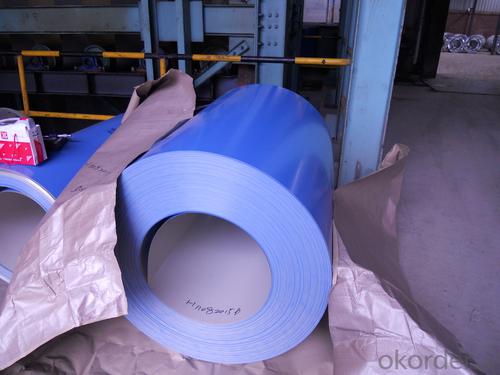

COATED STEEL COIL

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

PREPAINTED GALVANIZED STEEL COILS

ZINC COATING:60g/m2 (-/+10g/m2)

COLOR: ACCORDING TO COLOR SAMPLE.

TOP COATING:5+13 MICRON, BACK COATING:5-7 MICRON;

COIL WEIGHT:3-5 ton

STANDARD:JIS G 3312

STEEL GRADE:CGCC

COIL ID:508mm

THICKNESS:0.2MM-1.8MM

WIDTH:800MM-1250MM

MIN.ORDER:50TON

PRODUCTION TIME:30DAYS AFTER RECEIVED DOWN PAYMENT OR CORRECT LC.

TOLERANCE:WIDTH 0,+3 MM,THICKNESS:+/-0.02MM,ZINC COATING:+/-15G/M2.COATING:-/+2MIC.

- Q: Is it just because brass is reloadable? But what makes it reloadable? What does brass bring to the equation that the steel cased ammo can't do?

- Steel okorder /

- Q: How are steel coils used in the manufacturing of building materials?

- Due to their strength, durability, and versatility, steel coils find wide application in the production of building materials. Typically, these coils are made from high-quality steel and shaped into a continuous, flat strip. One of the primary uses of steel coils in building materials involves manufacturing steel roofing and siding. To achieve the desired dimensions and profiles, the coils undergo a series of processes that involve cutting, shaping, and rolling the steel. Consequently, the resulting roofing and siding materials are highly durable and resistant to weather, enabling the construction of long-lasting building envelopes. Additionally, steel coils are essential in the production of steel studs, which are crucial components for constructing frameworks. By cutting and forming the coils into precise shapes, they are assembled to create sturdy and rigid frameworks for walls, ceilings, and other structural elements. Notably, steel studs offer various advantages such as a high strength-to-weight ratio, fire resistance, and dimensional stability, making them a popular choice within the construction industry. Apart from roofing, siding, and framing, steel coils are utilized in the manufacturing of various other building materials. These materials encompass steel pipes, beams, columns, and reinforcement bars, which are indispensable for constructing foundations, infrastructure, and structural elements. Furthermore, steel coils serve as raw materials for fabricating metal panels, doors, windows, and other architectural components. In summary, steel coils play an indispensable role in manufacturing building materials due to their provision of necessary strength and durability for robust and long-lasting structures. Their versatility enables the production of a wide range of building components, cementing steel coils as an invaluable resource within the construction industry.

- Q: My neighbor who has an older model mustang installed a steel clutch in it and has blown 4 transmissions as a result.Can any mechanic explain why a steel clutch would kill transmissions? What other modifications would the car need in order to prevent this?

- figger he would learn after a tranny or two...no reasion for any clutch to wreck a tranny.must b bad instalation..or he cant drive

- Q: I am getting a barn soon and I was debating between wood, and steel. I think steel would look nicer [painted of course] and I was wondering which is cheaper. Any extra info would be great. Thanks x

- steel would be cheeper and last longer

- Q: Does anyone have any idea where I could get a necklace that has the British Steel by Judas Priest logo?

- Bristish Steel...ROCKS!!! Ebay is a good suggestion but if its something custom like that you could always bring in a drawing or picture to a jeweler and they can source it for you ;) I did something similar and the jeweler actually made it custom for me.... just a suggestion :) Good Luck!

- Q: I read that contrary to popular belief, today's folded steel swords are only made that way for tradition and cosmetics. In the past steel was very impure and therefore had to be folded in order to make a good sword. Today's steel manufacturing provides very pure steel and so folding the metal only makes it look nicer, but does nothing to improve the function of the blade.What do you think of this?

- Folded Steel

- Q: I need to know the density of steel as one of my physical properties of steel. Any answers? If u have more physical or chemical properties of steel, that would help to thanks.

- The short answer to your question is that the density of plain mild steel is 7.85. The long answer is that depending on where you look, or the grade of steel that you are talking about can change this value. A density of 7.88 is often quoted for mild steel as well. If you add alloying elements such as tungsten, chrome or manganese to improve the steel, the density will change. So the long answer is that the density of steel can vary between 7.75 and 8.05.

- Q: What are the challenges in welding steel coils?

- In order to guarantee successful and high-quality welds, it is necessary to address various challenges encountered when welding steel coils. One primary challenge involves achieving appropriate joint preparation. Steel coils often exhibit different surface conditions, such as rust, scale, or oil, which must be cleaned or eliminated before welding. This demands extensive cleaning and preparation to establish a clean and reliable welding surface. Another challenge lies in controlling the heat input. Due to the thin nature of steel coils, excessive heat can result in distortion, warping, or even burn-through. Welding operators must exercise careful control over the heat input to prevent such issues and uphold the integrity of the coils. Additionally, the presence of residual stresses poses a significant difficulty. Steel coils typically endure various stresses during the manufacturing, transportation, and handling processes, which can lead to distortion or cracking during welding. To mitigate these stresses and prevent potential defects, sufficient preheating and post-weld heat treatment may be necessary. Ensuring proper weld penetration is also of utmost importance. Steel coils often possess varying thicknesses, making it challenging to achieve consistent and adequate weld penetration throughout the joint. Welding operators must select appropriate welding parameters and techniques to guarantee complete fusion and a robust bond. Lastly, the size and weight of steel coils can create logistical challenges during welding. Specialized equipment and precise positioning are required to handle large and heavy coils, ensuring safe and efficient welding. Additionally, the length of the coils may necessitate multiple passes or continuous welding, demanding skilled operators and meticulous coordination. In conclusion, welding steel coils necessitates careful attention to joint preparation, heat control, stress relief, weld penetration, and logistical considerations. Overcoming these challenges guarantees the production of welded steel coils that are of high quality and durability.

- Q: What is the process of uncoiling a steel coil?

- The process of uncoiling a steel coil involves using specialized equipment, such as a decoiler or uncoiler machine, that is designed to carefully unwind the tightly wound coil. The coil is typically mounted onto the machine's mandrel, which holds it securely in place. As the machine rotates, the coil starts to unwind, with the outer layers gradually releasing and straightening out. This process continues until the entire coil is uncoiled, resulting in a flat and straight steel sheet or strip ready for further processing or use in various applications.

- Q: How are steel coils used in the production of appliances?

- Steel coils are used in the production of appliances as a primary material for constructing the various components, such as the outer shells, frames, and internal structures. The coils are processed and shaped into specific sizes and forms to meet the requirements of different appliances. Additionally, steel coils provide strength, durability, and a sleek appearance to the finished appliances.

Send your message to us

COATED STEEL COIL

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords